Aluminum Sheets for Sale Philippines - Painted Aluminum Sheet for Composite Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Painted Aluminum Sheet for Composite Panels

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Painted Aluminum Sheet for Composite Panels

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

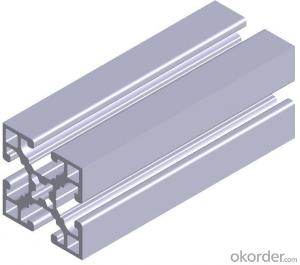

3. Painted Aluminum Sheet for Composite Panels Images

4.Specification of Painted Aluminum Sheet for Composite Panels

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: How to distinguish fluorocarbon spraying and powder spraying aluminium plate

- 2, fluorocarbon spraying is a kind of electrostatic spraying, and liquid spraying methods, called fluorocarbon spraying called curium oil, Hongkong. Belonging to high-grade spraying, higher prices, has long been applied in foreign countries.

- Q: How is aluminum sheet made?

- Aluminum sheet undergoes a rolling process to be manufactured, known as rolling. This process entails passing a preheated aluminum ingot through a succession of rolling mills. The initial step involves heating the ingot to a specific temperature to enhance its malleability. Once heated, the ingot is then fed through a sequence of rolling mills, wherein it is continuously pressed and stretched to reduce its thickness and increase its length. The rolling mills consist of a pair of rotating cylinders with grooves on their surfaces. As the ingot passes through these cylinders, it undergoes compression and elongation, resulting in a thinner and longer sheet. This process is repeated multiple times, with each pass further reducing the sheet's thickness. To maintain the desired thickness and dimensions, the sheet is periodically subjected to annealing. This process involves heating the sheet to a specific temperature and gradually cooling it. Annealing helps alleviate internal stresses and ensures the sheet retains its desired properties. Once the desired thickness is achieved, the aluminum sheet is cooled, trimmed, and either cut into specific lengths or rolled into coils for further processing or distribution. The final product is a flat, thin, and versatile sheet of aluminum that finds applications in various industries, including construction, automotive, packaging, and electrical appliances.

- Q: Are aluminum sheets suitable for food packaging?

- Yes, aluminum sheets are suitable for food packaging. Aluminum is a lightweight, non-toxic, and corrosion-resistant material that provides an effective barrier against moisture, oxygen, and light. It helps preserve the quality, taste, and freshness of food products, making it a popular choice for packaging perishable items. Additionally, aluminum is recyclable, making it an environmentally-friendly option for food packaging.

- Q: An aluminum clock pendulum having a period of 1.00 s keeps perfect time at 20 degrees celcius. (A) When placed in a room at a temperature of -5.0 Celcius, will it gain or lose time? (B)How much time will it gain or lose every hour.

- A for a swinging pendulum period T =2pi*√(L/g), where L is length of the pendulum, g=9.8m/s^2; metals shrink when cooled, so period will decrease, number of ticks per hour will increase, the clock will hurry up; B? period at t1°=20C° is T1=2pi*√(L1/g); ? period at t2°=-5C° is T2=2pi*√(L2/g); ? the law of linear extension says L2/L1= 1+s*Δt°, where s=23.1·10-6 (1/К°) is specific linear extension of aluminum, Δt°=t2°-t1°; ? thus T2/T1 =√(L2/L1) = √(1+s*Δt°) =f1/f2, where frequency f1= 1 Hz at 20C° or 3600 ticks per hour, hence frequency at -5C° is f2= f1/√(1+s*Δt°); therefore instead of 3600 ticks per hour the clock will do 3600/√(1+s*Δt°) ticks per hour; thus it will gain 3600*(1/√(1+s*Δt°) –1) = = 3600*(1/√(1 -23.1·10-6 *25°) –1) = 1.04 s/hour;

- Q: Are aluminum sheets suitable for roofing?

- Yes, aluminum sheets are suitable for roofing. Aluminum is a popular material for roofing because it is lightweight, durable, and resistant to corrosion. It is also non-combustible, making it a safer option for roofing. Aluminum sheets are easy to install and maintain, and they can withstand harsh weather conditions such as heavy rain, snow, and wind. Additionally, aluminum is a sustainable material, as it is 100% recyclable, making it an environmentally friendly choice for roofing. Overall, aluminum sheets provide a long-lasting and reliable roofing solution for both residential and commercial buildings.

- Q: I need to make an aluminum cylinder out of 1/8 6061 plate and tube. I don't have a TIG setup and was considering using Bernzomatic aluminum soldering rods. The cylinder will be pressurized from 20-60 psi. Assuming a clean job, is this pressure ok? How much pressure can the joint take? Also, although the solder does not need flux, should i use it anyway?

- to your setup i might merely persist with the iron. It would not sound like the burden mark downs is going to be properly actually worth the greater suitable probability for a on a regular basis motive force. forged iron is merely greater rugged and can take greater abuse than aluminum. Aluminum has its place yet its no longer in a on a regular basis motive force like it variety of feels you're development.

- Q: What is the standard size of an aluminum sheet?

- The standard size of an aluminum sheet can vary depending on the specific application and industry. However, common standard sizes for aluminum sheets range from 4 feet by 8 feet (48 inches by 96 inches) to 5 feet by 10 feet (60 inches by 120 inches).

- Q: Is it possible to use aluminum sheets as a material for exterior wall covering?

- <p>Yes, aluminum sheets can be used for exterior cladding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum is lightweight, which makes it easier to install compared to heavier materials. It also has good thermal properties, helping to insulate buildings. Additionally, aluminum can be coated with various finishes, allowing for a wide range of aesthetic options. However, it's important to ensure proper installation and sealing to prevent water infiltration and to maintain the cladding's performance over time.</p>

- Q: I just built a stone wall with illuminated glass features embedded, and to make them shine evenly, I had all sides but the visual one wrapped in industrial thickness aluminium foil. One week later, the foil has disintegrated. I have used type 10 Portland. What is going on?

- Embedded aluminum roof flashing, aluminum water stops, aluminum electrical conduit, introduced aluminum powder (sometimes used to foam concrete), or embedded structural aluminum shapes may all corrode in concrete or mortar. In all cases, a reaction that forms aluminum hydroxide and hydrogen gas occurs, and may cause expansion and cracking of the concrete or mortar. The common use of calcium chloride (or other alkali compounds), and dampness of the concrete increases the reaction rate. Usually, coating the aluminum with bituminous paint, impregnated paper or felt, plastic, or an alkali-resistant coating will prevent or sharply reduce the corrosion.

- Q: Is it possible to use aluminum sheets for creating personalized designs or artwork?

- <p>Yes, you can use aluminum sheets to create custom designs. Aluminum is a versatile material that can be cut, shaped, and bent to create various designs. It is lightweight, durable, and resistant to corrosion, making it suitable for both indoor and outdoor applications. You can use techniques such as laser cutting, engraving, or bending to personalize aluminum sheets for your specific needs. Additionally, aluminum can be anodized or painted to achieve different colors and finishes, further enhancing the customization options.</p>

Send your message to us

Aluminum Sheets for Sale Philippines - Painted Aluminum Sheet for Composite Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords