Aluminum Sheets for Sale Philippines:Aluminium Sliding Window Interior Window Frame

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Sliding Window Interior Window Frame Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Sliding Window Interior Window Frame :

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

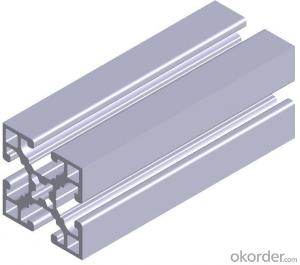

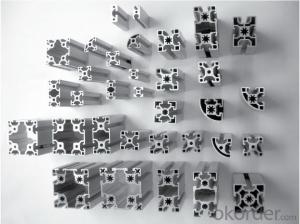

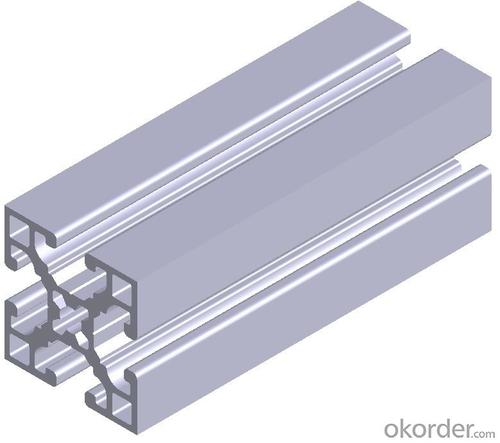

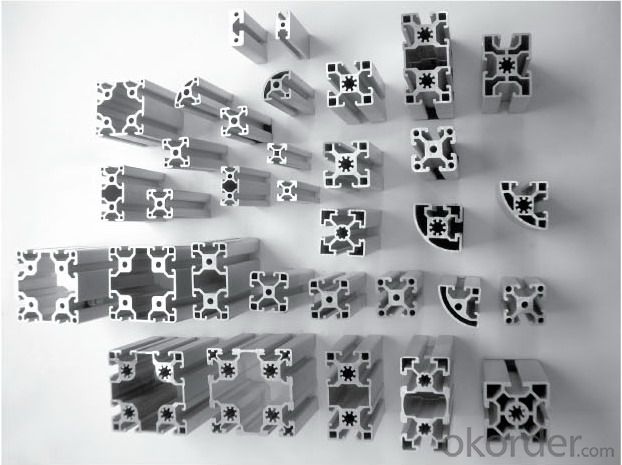

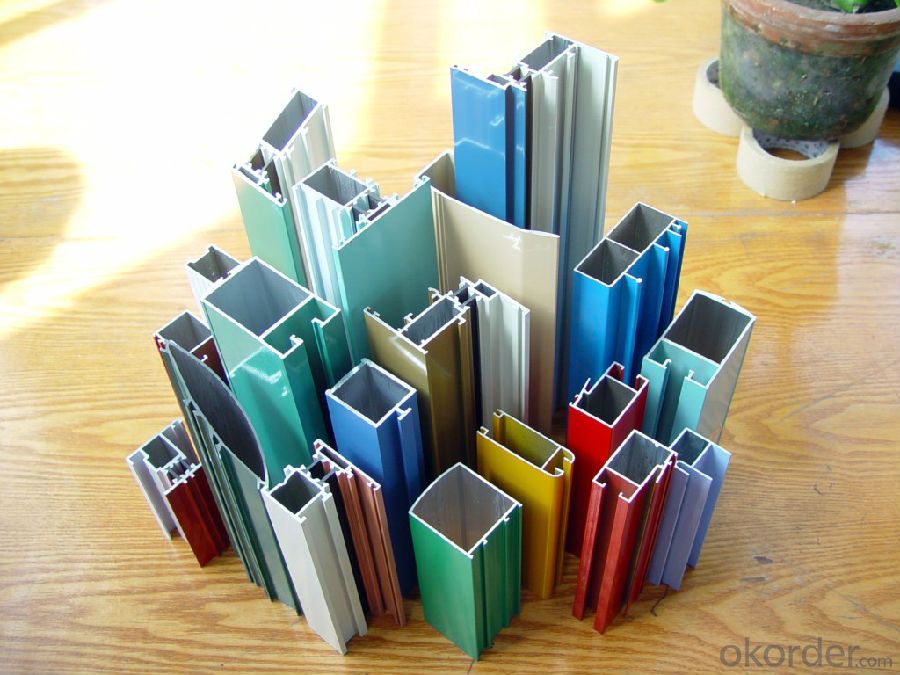

3.Aluminium Sliding Window Interior Window Frame Images:

4.Aluminium Sliding Window Interior Window Frame Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the limitations of using aluminum sheet?

- There are several limitations to using aluminum sheet. Firstly, it has a lower strength-to-weight ratio compared to other materials like steel. This means that aluminum sheets may not be as strong and durable in certain applications. Additionally, aluminum is prone to corrosion, especially in harsh environments, so proper protective coatings or treatments are necessary. Aluminum sheets also have limited formability compared to materials like steel, which can impact their use in certain complex shapes or designs. Lastly, aluminum sheets can be more expensive than other materials, which may affect their affordability in certain projects.

- Q: Explain the distinctions between aluminum sheets and aluminum foil in terms of thickness, uses, and properties.

- <p>Aluminum sheets and aluminum foil are both made from aluminum but differ in thickness and applications. Aluminum sheets are thicker and more rigid, typically used for construction, manufacturing, and as a packaging material. They offer better strength and durability. Aluminum foil, on the other hand, is very thin and flexible, commonly used for food packaging, cooking, and insulation. It's lightweight and has excellent heat and light reflection properties. Aluminum sheets are often anodized or coated for additional properties, while foil is valued for its purity and malleability.</p>

- Q: Can aluminum sheets be used for air conditioning systems?

- Indeed, air conditioning systems can make use of aluminum sheets. Due to its remarkable heat transfer properties, aluminum is widely employed in the fabrication of air conditioning systems. Its lightweight nature, resistance to corrosion, and exceptional thermal conductivity render it a perfect material for producing coils, fins, and heat exchangers within air conditioning units. Furthermore, aluminum sheets can be effortlessly manipulated and molded into diverse forms and dimensions, thereby enabling flexibility in both design and installation.

- Q: What is the electrical resistivity of aluminum sheets?

- The electrical resistivity of aluminum sheets is approximately 2.65 × 10^-8 ohm·meter.

- Q: Can 101 aluminum sheets be used in the production of nameplates or tags?

- Yes, 101 aluminum sheets can be used in the production of nameplates or tags. Aluminum is a popular material choice for nameplates and tags due to its durability, lightweight nature, and resistance to corrosion. The 101 aluminum alloy, which is a commercially pure aluminum, offers excellent formability and workability, making it suitable for various manufacturing processes such as stamping, engraving, or etching. It can be easily cut, shaped, and customized to create high-quality nameplates or tags with clear and precise markings. Additionally, aluminum's ability to withstand harsh environments and its attractive appearance make it a preferred choice for many industries, including automotive, aerospace, electronics, and signage. Therefore, 101 aluminum sheets are a suitable material for the production of nameplates or tags.

- Q: Hi I am getting a laptop pretty soon and have pretty much decided on a Mac. But really a white macbook is $1150, and aluminum is $1400. And just so no one says this, the white one is updated with all the same hardware(Advanced graphics, etc.) I want to get it asap so the $250 would mean about 2 months longer which would kind of be a drag. I also understand the aluminum doesn't have a firewire port, but idk what the hell that even is so can someone explain what it is and why I would care about it. Basically, is it worth the 2 months and $250 for the aluminum. Thanks.

- There is no difference between the plastic/aluminum on the inside at all except for the firewire port, and some of the aesthetic differences (the aluminum one just looks cooler in my opinion, the lcd is behind the glass panel, the trackpad is made of glass too, and the battery meter is on the side, not underneath like the white macbook). Firewire is IEEE 1394, it's like USB but not used as much except with high-speed external hard drives and digital video cameras (which can be used with video editing software on Macs). It is faster than USB.

- Q: who knows the ceiling technology of aluminum sheet?

- Construction technology of ceiling aluminum sheet: (1) firstly check keel’s quality, the straight shape and uniformly forced state of boom, control the keel’s gap within 500mm, reduce the gap according to design requirement under humid environment. The lower surface of keel is smooth without a sense of bearing down, main device is closely connected with accessories, it can be bound after being confirmed qualified.(2) we should break the board along the cutting line and ensure the margin of cutting board straight and square without any chipping or arris defect. (3) while placing and fixing the board, we can place edge of aluminum-plastic panel(encapsulated edge) in the vertical direction of supporting keel, there is a phenomena of hanging. Aluminum-plastic panel should be placed closely in the process of butt joint, it can’t be pressed. You can start from a plate angle or middle position, and don’t place them at the same time. Slab joint should be straight and in the same width, without break joint. (4) in the process of joint, Aluminum-plastic panel should be placed closely in the process of butt joint, it can’t be pressed. And the butt joint should be stagger, the butt joint can’t be connected on the same keel. When you use doubling plate, the joints of the second layer board and the first layer board can’t be connected with the same keel, double-deck gypsum board should be staggered joints.

- Q: Aluminum knowledge. What is the model 3003 H24? What does H mean?

- H: work hardening state.(1) Hxx state:H1 * - hot rolling, Zhang Liqiang; H2 * - continuous casting and rolling, Zhang Liqiang, part of the toughening; H3 * - after stress treatment, stable performance; H4 * - after paint or coating; H x 2 - 25% x 4 - H hardness; hardness 50% processing; H * 6 - 75% hardness; H * 8 - 90 more than the hardness.(2) Hxxx state:H111: suitable for the final annealing, but also a proper amount of work hardening, but the degree of hardening is not as good as the H11 state of the product.H112: for hot forming products, the mechanical properties of the condition are specified.H116: made for magnesium content more than 4% 5 * * * alloy products. These products have specified mechanical properties and anti stripping corrosion resistance requirements.

- Q: What are the safety standards for using aluminum sheets in construction?

- <p>Yes, there are safety standards related to using aluminum sheets in construction projects. These standards ensure the material's structural integrity, durability, and safety. They include specifications for thickness, strength, and quality of aluminum sheets, as well as guidelines for their installation to prevent issues like corrosion, fire hazards, and structural failure. Compliance with these standards is crucial for the safety of the construction workers and the longevity of the building.</p>

- Q: This question asks about the ability of aluminum sheets to withstand weather conditions without deteriorating.

- <p>Aluminum sheets have excellent weathering resistance. They are highly resistant to corrosion and oxidation, which makes them suitable for outdoor applications. Aluminum forms a protective oxide layer when exposed to air, which prevents further corrosion. This property allows aluminum sheets to maintain their appearance and structural integrity over time, even in harsh weather conditions. Additionally, aluminum can be coated or anodized to further enhance its resistance to weathering.</p>

Send your message to us

Aluminum Sheets for Sale Philippines:Aluminium Sliding Window Interior Window Frame

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords