Outdoor WPC Decking/ Wood Plastic Composite Decking Manufacturer /Direct Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Outdoor WPC Decking/ Wood Plastic Composite Decking Manufacturer /Direct Factory

一.Product Description:

.

Low flame spread / High slip resistance / No sting of wood / Contains no toxic chemicals or preservatives / Environmental friendly / Can be recycled with 100%

• High Strength

Outstanding screw and nail retention / High impact resistance / Great Compressive-tensile-shear strength / Modulus of elasticity: 20% greater than PVC

• Good appearance & nice touch

Natural feel & wood touch / Broad range of finishes and appearance, Multicolor, and needn't to painting

• Longevity

Its lifespan at least 10-15 years in the outdoor weather condition

• Install & Maintain easily

Easy to produce and easily fabricate / Easy to cut, fix and glue; Easy to tenon, drill and nail / Require less routine maintenance / No need staining & water Sealant

Competitive Price

• Using most advanced machinery to increase the output and reduce the costs.

Strong technical support from famous institute of high polymer to guarantee the best quality as well as cost saving.

• Neighboring one of the biggest wood/ bamboo processing industry region and having a special purchase channel of the raw materials (Plastic and wood/bamboo fiber)

• As a high technology and environmental-friendly enterprise, supports form the government such as reduction and exemption of tax rate are available.

escriptions :

The characteristics of Wood generally had the problem of Waterproof and the serious concern to the environmental protection has been increasing day by day as well as it caused the Governments worldwide to stipulate the law to restrict to fell trees to reach the goal. To satisfy with the market's demand we utilized the characteristics of macromolecule to combine with the high technology of heavy pressure-micro foaming to produce an unique product with the invention and innovation of revolution. We call this new product " CELLwood®".

Properties :

1. 100% recyclable product meets with the environmental protection without

adding any wood flour or sawdust.

2. 100% waterproof.

3. Suitable to be used for the activities indoor and outdoor.

4. The component with high quality features that the density is similar to the wood

(D:0.6~0.7 g/cm3) and light.

5. The processing is similar to the general timber, e.g.: shave, saw, trim, nail, drill,

wash and grind.

6. Strong rigidity and durability. (Similar to teak)

7. Thermal process is easily executed to be blended to have various shapes of the

materials.

二.Technical Data

Slip resistance:

Boards of Techwoodn according to ASTM D2394-05. This is the best ranking for bare-foot slip resistance.

Weathering resistance:

Boards of Techwoodn have very low moisture uptake.This is key for mold and mildew resistance.

UV resistance:

4000 hours accelerated Xenon-arc Exposure,the Boards turned slightly more clear and colored.

Abrasion resistance:

The resistance to abrasion is similar to oak.

Fungus resistance:

Whatever fungus the wood composite is exposed to,it is extremely durable.

Moreover,aging test does not affect this durability.

三. FAQ

. What kinds of wpcproducts do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

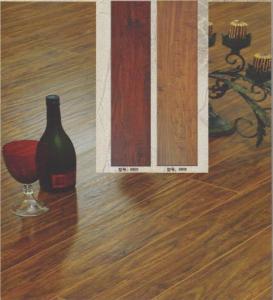

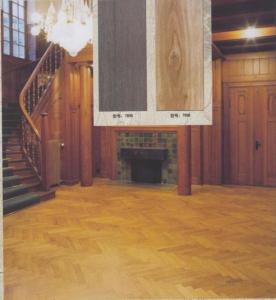

四. More picture for your reference

- Q: What is the moisture-proof mats for solid wood flooring?

- Manufacturers equipped with moisture pad

- Q: Please refer to the ceiling for the floor, or the floor, how does its ownership confirm?

- Separate the adjacent part of the owner of the partition, beams, columns and floors, are adjacent to the owners of the total. Legal basis: "People's Republic of China Property Law" Experts recommend the development of property law supporting the law to avoid decoration disputes Separate walls, beams, columns and slabs of the exclusive part of the adjacent owners are part of the adjacent owners; ? 2 roof floors, floor flooring and The outer wall belongs to the inside side of the owner and other owners, the roof floor and the outer side of the external walls shared by all the owners, while other owners to use the pipeline, lines and other ancillary facilities, are related to the owners.

- Q: we had a floating floor put down...after all was said and done....the floor looks like it has waffles in it...has anyone seen this? It's light oak...it's ugly and fake looking....speant 13,000 on it...or is this the way it's suppose to look?

- Cant imagine spending 13k on a laminate floor. I did my frontroom last year and I believe I spent like $300 total on the flooring and padding. It took 1 day to do. Is your house like 25k square feet or something? Anyhow, no idea what flooring you picked out, not too sure how you would not have an idea how it would look when done, the planks are large enough to get the idea.

- Q: hen I was in Florida I went to a hotel called the crown plaza in Orlando and I was in the lift when I noticed there was a fourteenth and and a twelfth floor but no thirteenth floor and It wasn't a staff floor or anything cause I counted the floors on the way up by looking at the numbers on the walls ( It was a glass lift) . Anyway I was wodnering do you think it's something paranormal ? or did they just forget to put the floor there? Or is it a superstitious thing?

- It's a superstitious thing. The number 13 is associated with bad luck in some countries, and even has a specifically recognized phobia, Triskaidekaphobia, a word which was coined in 1911. Friday the 13th has been considered an unlucky day since the 1800s, as a combination between an unlucky day, Friday, and the number 13. The levels of a multi-story building are numbered sequentially, from basement, one or ground upwards. In some countries, the number 13 is considered unlucky and building owners will sometimes purposefully omit a floor so numbered.[1] Hence, the 13th floor is given the number 14. Even landlords who are not themselves superstitious realize that the desirability of suites on a floor 13 might be compromised because of superstitious tenants, or commercial tenants who worry about losing superstitious customers. Based on an internal review of records, Dilip Rangnekar of Otis Elevators estimates that 85% of the buildings with elevators did not have a floor named the 13th floor.[2] Also the Disney ride The Twilight Zone Tower of Terror is known to have 13 floors, even though the dial on the elevator goes to 12. When on the elevator the doors have the numbers 13 on it, showing that the floor should not exist.

- Q: without putting all the dirt from the floor into the grout joints.

- sweep or vacuum up all dirt, dust, loose debris. Use warm water and a tile cleaning agent and if it's not gross dirty just mop it or use a cloth. If it's horrid, scrub with a stiff brush. When it's dry, use a grout cleaner --really smelly and lots of elbow grease, but they work --then when it's dry seal your grout. Sealants are pricey but so worth it. Henceforth you will only need to mop. voila

- Q: MY 2ND BATHROOM FLOOR STICK ON TILES ARMSTRONG TYPE ARE STARTING TO BLEED WATER THROUGH THE CRACKS , WHATS UP

- Peel and sticks aren't really going to stand up to bathroom use. They are better off used in a foyer or mudroom. Go with a single sheet of linolium or real tiles with grout!

- Q: I am looking to replace the flooring in my bathrooms

- It depends on what kind of flooring you want to install, and what is already on the floor. If you are going to install a sheet vinyl, and there is more than one layer of existing flooring you will have to remove the old flooring. Then you will probably have to install 1/4 luan or plywood underlay first. Then you will have a nice smooth surface for the new floor. If there is only one layer of existing flooring and it is smooth and tight you should be able to install the new vinyl right over it. Some vinyls have to be glued fully, and then there are others that are only perimeter glue. You should remove the stool, install the new floor, a new seal under the stool and replace it.

- Q: How to clean the wood floor is the best cleaning

- Strengthen the composite floor is basically not deliberately maintenance, strengthen the composite floor is based on the density of fiberboard or wood as the substrate, and with special wear-resistant plastic as a cladding material made of Ding Ding Dian shares Karma Dali lost stem a plate, the surface Smooth, wear-resistant stains, so waxing useless, can not penetrate, so as long as the usual cleaning, with a little wet mop can be wiped, and do not use a very wet mop to wipe.

- Q: We have wood laminate floors in our new kitchen, and I feel like they always look dirty. (I have two young boys, so really they ARE always dirty, but I'd like them to look clean at least when I first mop!!) No matter what I use, they always look dull. I have tried **** & Span, Murphy's Oil Soap, and some other things. All of them seem to leave a film. What is the best way to clean wood laminate flooring to make it shiny? Thanks!

- There okorder /... I use it for my hardwood. The clothes are machine washable and they last for a long time! wash great. I also think you can buy refills and new cloths at Bed Bath and Beyond... no positive because I just order mine online. But try it out and see if you like it. I am hesitant over any steam mop because as recommended by the manufacturer... never steam clean your laminate... it can really mess it up. So I play it safe.! Hope this helped! :)

- Q: To do a 1500 * 80 * 80 cm fish tank, the weight of the water after the installation of 1 ton, do not know whether the building floor can withstand more

- Can, remember that our home decoration when the cement and gravel used more than three tons.

Send your message to us

Outdoor WPC Decking/ Wood Plastic Composite Decking Manufacturer /Direct Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches