Wood and Plastic Composite/Outdoor Decking/WPC

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Wood Plastic Composite Decking

The WPC decking is a new material, combine the nature look of a wood deck with the advantages of a weather-resistant, stable, easy to clean, and sturdy high-tech material and quite follow the trend of wood substitute.

Application of Wood Plastic Composite Decking

widely used for outdoor decking floor,Wall panel.railing,fence,bridge,dock,gloriette,gazebo,boardwalk,etc

Advantage of Wood Plastic Composite Decking

1. With the look of the natural wood but less timber problems, Approx. 90% recycled materials

2. Weather resistant, suitable from -40 to 60 °C

3. Resistant to termite and insect attack, will not split, rot or warp

4. Cuts and drill like timber

5. Requires no painting, no glue, low maintenance effort

6. Easy to install and clean

Packing of Wood Plastic Composite Decking

Packaging Detail | 112pcs per pallet, 16pallets per 20ft, 24 pallets per 40ft. pallet size:290x105x1375px |

Delivery Detail | 15 days after received the deposit |

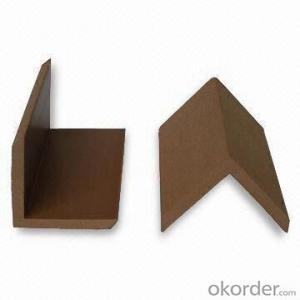

Pictures of Wood Plastic Composite Decking

Specification of Wood Plastic Composite Decking

component | 30%HDPE+60%bamboo/wood fiber component+10%chemical additives |

Length | 2.2m, 2.9m, and 5.8m or customized |

Size | 140X20mm,150X25mm,145 X21mm,145 X25mm, etc |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE, Walnut, gray stone, Cedar, Rosewood) and we can adjust the new color according to the order requirement |

FAQ

We have organized several common questions for our clients,may help you sincerely.

1. How about your company?

Our company is a world class manufacturer & supplier of Wood Plastic Composite and is one of the large-scale professional investment Wood Plastic Composite bases in China. Annually more than 1000 containers of Wood Plastic Composite bases are exported to markets in Europe, North America.

2. How to guarantee the quality of the products?

We can supply certificates, including ISO9001, ISO14001, CE, FSC Certificate, "REACH" Test Reports by SGS; Intertek Test Report by ASTM standard..etc.

3. How to install the WPC decking?

Installation tool: electric saw (desk type or portable),churn drill, electric portable drill and driver

Decking and accessories: 1.decking 2.joist 3.metal clip 4. plastic expansion screws 5.start clip 6.fascia

Installation step:

1. Fix the joist. 2. Decking installation. 3.Fascia installation

- Q: the underfloor heating guys are screeding heating mesh to conctrete floor. I need to know the procedure for gluing an engineered floor to screed. thank u.

- If I were you I would contact the flooring manufacturer for their recommended procedures rather than soliciting advice that may or may not be correct for your situation - ask the heating guys what material they are using to float the floor with so you can get the correct info

- Q: What kind of composite flooring is good?

- Now the use of composite floor decoration room has been very wide, but the different brands of composite flooring in the performance indicators there is a big difference I personally think that the best choice on the market relatively large brand, so the quality and after-sales service Satirical kettle is better, such as Sao Paulo, icons, nature and so on!

- Q: It is good or seamless for the elephant floor

- There are two kinds of composite floor chamfering plate and molding plate. There are cracks for the chamfering board, seamless for the molded plate: carefully observe the chamfering board around the paint for the edge, there is no wear-resistant layer, and can not be a strict fit, the middle of a gap will seepage into the seepage, Good care. At the same time the paint side will be 1-2 years off, the substrate exposed to the outside, the water will penetrate into the substrate greatly affect the life of the floor. And the pressure plate wear layer is extended to the edge of the surface is a whole; combined with the assembly after the tight seam, just to make up for the lack of chamfer board. Another key can not be ignored is the lock, chamfering board is often flat buckle, in the process of flat buckle easy to fall off; and the new arc intelligent deduction bite force to avoid the use of the process of the above problems. Choose the floor to choose the floor as long as the sharp eyes, identify the substrate · wear-resistant technology do not have to spend the blood of this still can buy a satisfactory floor.

- Q: After the floor of my house is finished, the flooring company says it does not need waxing is compounded, is it like this?

- Do not need a composite floor strength is high 2 composite floor surface is not a solid wood material but posted a layer of skin, do not need special protection.

- Q: How to strengthen the composite floor?

- Reinforced wood flooring accessories installation requirements: 1. The bottom mat can prevent the floor by wetlands, and between the ground and the floor from the buffer effect. When the mat is installed, the mats and mats can not overlap, and the interface is sealed with tape. 2. Geothermal ground, the first floor and large shopping malls and other ground to add 0.2 mm thick film, and every two films should be overlapped every 200 mm, and sealed with a tight strip. 3. Electric heating The ground is recommended to use anti-aging, good thermal conductivity of the material as a mat, in the full improvement of flexibility and reduce noise at the same time, electrical insulation protection must be improved. {TodayHot} 4. The quality of the skirting board must also meet the national standard requirements. Pavement process requirements: 1. Before installing the floor, doors and door sets must be set to the appropriate height to ensure the installation of the floor. 2. The floor of the pavement, requiring seams tight, no significant difference between high and low, no obvious gap. 3. The floor of the floor is determined by the special pad of adjustable width. 4. Construction, as far as possible to maximize the savings of materials. 5. When installing the skirting board, the height of the hole on the wall to be consistent, shall not damage the pipeline within the wall. 6. Requirements skirting board at both ends of the seam tight, highly consistent.

- Q: Granville lion composite floor and giant Ning composite floor which is good

- Granville lion composite floor and giant Ning composite floor are just the general floor brand. It is recommended to buy the brand to bear the edge of Cao Gu 丨 ordered to check the taper plate. Top 10 brands of flooring: Nature floor flooring Top ten brands of 2: Saint elephant floor flooring Top ten brands of 3: Ferguson wood flooring floor Top 10 brands of 4: Del Wood floor flooring Top Ten brands of 5: Wooden floor flooring top ten brands of 6: life home floor flooring top ten brands of 7: Rhine Sunshine wood flooring top ten brands of 8: Anxin wood flooring floor of the top ten brands of 9: Cicero wood flooring top ten brands of 10: Ruijia wood flooring

- Q: I'm taking out carpet - under it is a layer of linoleum and it is down on a cement slab. It is tight and down solid.... is there really any reason to remove it? Advantages/Disadvantages???? Any advice welcome

- Do not remove the linoleum. You do not need the plastic bubble underlayment for a floating hard wood floor if you have a good grade of linoleum down. The linoleum will work as good or better than the plastic underlayment.

- Q: Strengthen the composite floor environmental protection do

- As long as meet the national standard, is the health of the floor.

- Q: Will the professionals, strengthen the composite floor really can not touch a drop of water? If it is true

- You ask, it is very professional, all wood products will have a water content of a standard

Send your message to us

Wood and Plastic Composite/Outdoor Decking/WPC

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords