Wood Plastic Composite Decking Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Place of Origin: | ||||

| Model Number: | Technics: | Size: | |||

| Technique: | Section: | Feature: |

Packaging & Delivery

| Packaging Detail: | Carton/Pallet |

| Delivery Detail: | 5-15 days |

Specifications

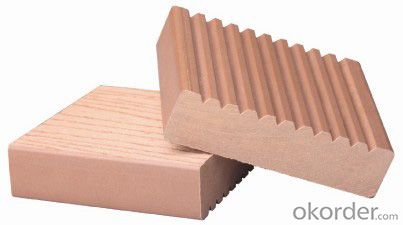

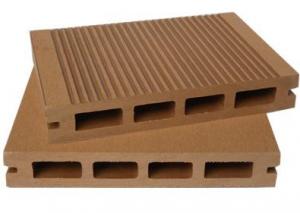

Outdoor wood plastic composite decking

1-Energy-saving

2-Renewable

3-Less maintenance

4-Long lifetime

Dear Customer, We are WPC Decking Direct FACTORY, Welcome your Inquiry.

Product Informatin:

Description | Outdoor Wood Plastic composite engineered Decking |

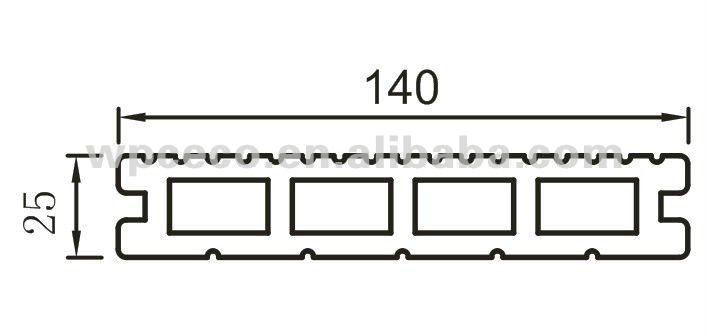

| Size | 140X25mm |

| Component | 30%HDPE+ 60%wood fibers +10%additives |

| Decking section |  |

Certificate | ISO, MA, Intertek |

| Main Feature |

1.having a natural wood texture. 2.Installation is simple with low cost. 3.waterproofing, moisture-proofing, pests-proofing 4.impact resistance, wear resistance and no distorting 5.suitable from -40°C to 60 °C 6.without paint, without glue, low maintenance costs 7.UV-proofing,color stability 8.100%recyclable, saving wood resources

|

Quality warranty | 15 years |

| Application | Swimming pool, garden, school, park, lawn,dock, playground, corridor, hotel , entertainment place, shopping center, laboratory ,living room , dance club , business hall, bathroom , massage room , etc . |

- Q: We are putting in maple floors and are considering engineered wood. Trying to research the engineered floors, I see alot of positives and not the negatives - yet there must be some! Any opinions?Also - would one be easier to install than the other?If it matters ... This is for the 1st floor our our house in South Eastern MA (about 6 miles from the ocean). Thanks

- the instalation is about the same, except if u go for the click connect vs nailing the boards down - the click is easiest. but your biggest concern shud b on the finish. if this flooring is going down in a high traffic area i would go for the best finish possible. fyi -- we have oak flooring in our kitchen n family room. the kitchen is about 8 years old and came pre-finsihed n has been showing signs of wear for years. whereas, our family room floor, we started w/raw wood n polyed (3 coats) it ourselves has been down for 3 years, this room is for our yard n garage access n is not showing any sign of wear. you may also want to consider this - both flooring types can b refinshed. with an engineered floor it will last for many decades. but a solid wood floor can last for over a century. i have lived in east boston n winthrop in older houses that still had the original hardwood flooring. good luck

- Q: Can tile flooring be on the floor?

- Can shop, but there is a problem. If you shop on the floor tile and then shop the floor, then your room will increase the height of the ground. It is estimated that the door has to change, and if you only shop room, then the living room than the room floor is very ugly. Personally suggested to knock the floor to re-leveling the ground and then shop the floor.

- Q: My home is warm, has been heating, the composite floor was blisters how to do

- How could it be blisters? Is it hot? If it is to warm the water, it is serious, and need to quickly find a professional to repair the replacement; valve Fen Huang Huang Yi No. wrong copper and nitrogen expansion of the floor was blisters, and can pry up the floor, drying sun, dry after no deformation, But also can be used, other deformation, can only be lost; but the proposed replacement, or else the new floor, the old floor, how many will have color, visually not good

- Q: Thank you for helping me? There is the price

- Solid wood flooring is made of wood, and composite flooring is generally done with the MDF, the two are fundamentally different, mainly to see its side, a look to know

- Q: What is the difference between composite flooring and tiles?

- To the occasion, the general bedroom and study more suitable for wood flooring. The kitchen, the bathroom is more suitable for tiles. One: tiles: tiles are often said floor tiles. Tiles are cheap, and easy to clean and clean, tiles are also wear-resistant. However, the tiles of the foot feel and decorative effect as wooden floor. Second: wood flooring: wood flooring is divided into solid wood flooring, parquet. 1) solid wood flooring: solid wood flooring is very healthy, environmental protection, decoration effect is good. In the price is more expensive, and not easy to install and maintain, need regular waxing. 2) parquet: solid wood flooring changed the previous physical structure, better stability. In the price, than the solid wood flooring to be cheaper, are middle consumer products. Is the home decoration in the more popular a class of ground decoration materials. 3) to strengthen the floor: to strengthen the floor is the biggest feature of wear resistance is good, very suitable for living room and other places more concentrated, is the wood floor varieties in the cheapest floor, is the working class people first floor decoration materials. However, in the installation and maintenance is very simple.

- Q: San Nair composite flooring is the brand?

- Not a big brand but environmental protection and waterproof wear are very good just too little advertising is not well worth

- Q: Home decoration, want to shop wood flooring, go out a circle, pure solid wood price beyond my budget, strengthen the floor style and more, the price of Fan Dun Dun stalk when the rudder when Jiang Jie close people, good care, among the Of the solid wood composite, the price is not cheap, but I can barely accept, aside do not say anything else, environmental protection in this area, really solid wood composite than to strengthen the floor ok? I read a statement on the Internet, solid wood compound is also a layer of glue with a layer of glue, might as well strengthen the composite it, the price is not very close to the people, which I am very tangled ~ Please understand your friends advice, thank you! ~ ~ ~ More

- These two kinds of plates will use glue bonding, but in general, the use of solid wood composite floor glue will be less than the composite floor, which is why the solid wood flooring than laminate flooring environmental reasons. But this is not absolute, and ultimately depends on the manufacturers of the production process, the state has expressly set environmental standards, if the solid wood composite floor with E2 production standards to strengthen the composite floor E1 production standards, it is E1 than E2 environmental protection. E0, E1, E2 is the environmental protection of formaldehyde emission detection of three different standards Synonyms: E0 ≤ 5 mg / 100 grams E1 ≤ 9 mg / 100 grams (generally said that the environmental protection board indicators) E2 ≤ 30 mg / 100 grams 1. Strengthen the floor: it has the advantage of cheap wear, strengthen the composite board is used to do the density board, MDF is made of wood powder +, airtight, poor foot feeling, impatience, no moisture. 2. Solid wood flooring: solid wood flooring (solid wood flooring) In addition to the advantages of solid wood flooring, but also the advantages of solid wood flooring, such as: not easy to deformation Alice, good maintenance, not Jiaoqi, etc.: ① solid wood flooring The substrate is mostly lianamine, breathable, comfort is better; ② with less glue, better environmental protection; ③ surface layer with van denen sturdy rudder when the fine solid wood thin slices, good-looking, the price is generally lower than similar Solid wood flooring; ④ it is generally used UV paint coating, but also the use of ceramic paint, wear resistance are better, but not as strong as complex;

- Q: New house ready to renovate, bedroom inside want to use composite floor, but I heard that the composite floor radiation, is true or false ah? The The More

- No radiation at ease

- Q: what is the primary differences between 5/16 and 3/8 engineered flooring - besides thickness?

- The price.

Send your message to us

Wood Plastic Composite Decking Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches