Bitumen Roofing Felt

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 Square Meter m²

- Supply Capability:

- 300000 Square Meter per Month m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

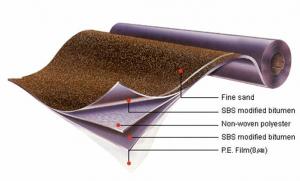

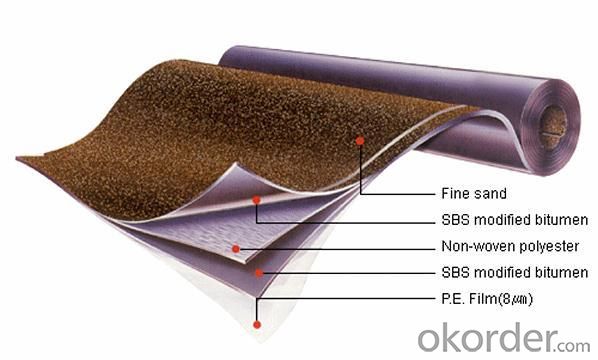

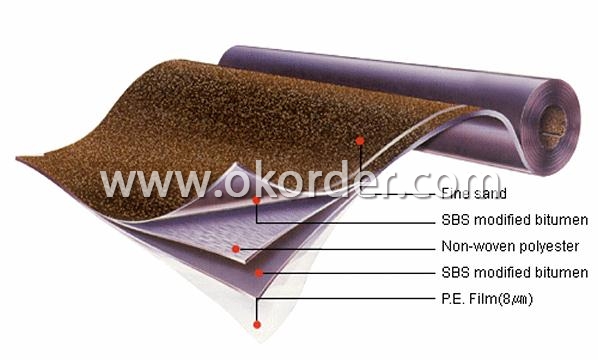

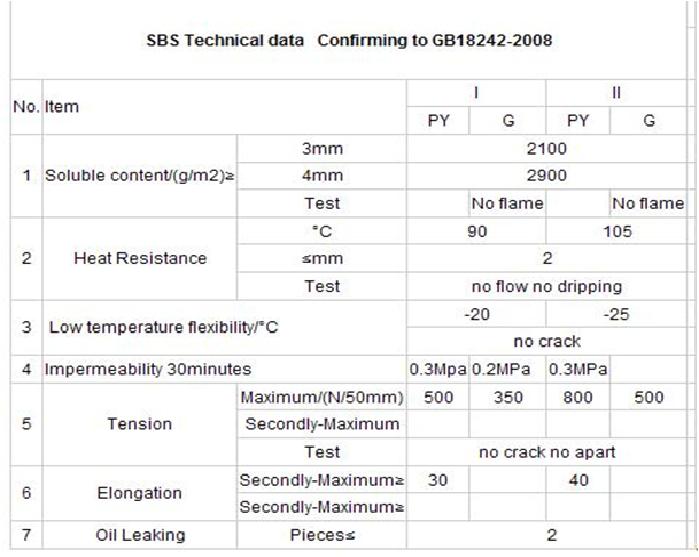

Specifications of Bitumen Roofing Felt:

1.Name: waterproofing roofing felt

2.Low temperature:-5,-10,-15,-20,-25

3.Surface whit PE,Sand, mineral material

4.Thickness:3mm,4mm,5mm

5.Application: roofing and wall,underground application

6.Characters: waterproofing

7.Packaging & Delivery Detail: in rolls

- Q: How to ensure the waterproof quality of the underground shear wall (retaining wall)?

- 3, according to the hydrogeological conditions and outdoor environment type to take the appropriate level of waterproof concrete.

- Q: Can acrylic materials be perforated? How to do waterproof after punching?

- Anti-corrosion nine PCT board size is greater than the size of the hole, that is, just in the hole on the nine-plate, This can play a certain role in strengthening.

- Q: Waterproof mortar expensive or dry mortar expensive

- Waterproof mortar more expensive. Because waterproof mortar compared to dry mortar, to add another waterproofing agent, emulsifier and other substances. Waterproof mortar regardless of the cost or transport are more cost-effective.

- Q: How do you make waterproofing in the kitchen and bathroom?

- Kitchen and toilet to do waterproof, it is recommended to use kitchen and toilet waterproof paste, it is specifically for the kitchen and toilet water and easy to seepage yin and yang angle, pipe, sanitary ware, floor drain and other parts of the development, special materials, so waterproof Ordinary waterproof material is better, and waterproof coating construction is more convenient, only need to brush 2-3 times, the thickness of 1.2-1.5MM on it. Specific construction methods are as follows: 1, will penetrate the root, floor drain and other cracks, need to repair the site cut into "V" shape, and clean, sprinkler moist; 2, the [infiltration of crystalline repair mortar] add water (water and ash weight ratio of 1: 2 ~ 3) mixed evenly, in the early condensate before (5 minutes) to repair the construction, the root of the pipe, the floor drain, yin and yang, Should be made r angle; 3, repair mortar after the final setting, the [durable waterproof paste] powder and liquid material mixing evenly, put it aside for 3 minutes, and then stir evenly after brushing on the base surface, should be cross brush twice, and so on The first time after the dry, can be carried out the second time construction; 4, after the completion of anti-stamped, 48 hours after the closed water test.

- Q: Do you use the waterproof material on the building to be harmful to the human body?

- Of course harmful, not just this particle, there are auxiliary materials are also toxic.

- Q: Roof leakage, what materials do the best waterproof

- The Second, if the roof is only the original did not do waterproof, only need to remove the leaky parts of 2 ~ 3cm deep after cleaning, you use asphalt irrigation, and now there is finished asphalt coating, such as sunny day when the treatment will basically not Leaked out. If there is a waterproof layer is too much trouble, to be around a range of waterproof tick, re-do waterproof, do when the attention and the original waterproof junction to do reinforcement layer. There are many ways to deal with leak detection, or to find some professional leak-proof companies to deal with this problem.

- Q: What should you pay attention to before the construction of the basement waterproofing membrane?

- Plastic runway construction should pay attention to: 1, before the construction, must be on the asphalt concrete foundation for quality acceptance, acceptance criteria according to design standards and technical specifications, the plastic runway in the corresponding drainage facilities, can be used around the clock. The ambient temperature should be controlled at 5 ℃ ~ 38 ℃, to avoid below 5 ℃, 38 ℃ above the ambient temperature operation, the relative humidity control below 70%, the foundation requires a clean, according to the temperature and relative humidity to adjust the amount of catalyst The curing speed control appropriate. Color paste and prepolymer storage, the lid to be tightened, before use to detect moisture, qualified after use, the water in the foundation should also be controlled to avoid the bubble after the glue. Plastic pavement materials must be carefully checked when the quality inspection certificate and validity period.

- Q: Why should the use of high pressure perfusion waterproof plugging method

- High pressure grouting construction principle: is a special high-pressure grouting waterproof material through the high-pressure infusion equipment into the concrete crack structure extended until all the cracks (including the naked eye is difficult to meet) filled with water (water) with the cross-linking reaction, Release a large number of carbon dioxide gas, resulting in secondary pressure, high pressure and secondary pressure will be pressed into the elastomer and filled with all the gaps, to stop the purpose of leakage, it can be said that the best performance of plugging material,

- Q: Developers have done waterproof, decoration house also have to do it

- Secondly, before the waterproof layer may be done in the house decoration, paving tiles or other equipment when the installation was destroyed, so that the waterproof layer is no longer a whole,

- Q: Finished house bathroom waterproof household acceptance should be how to accept?

- 3: waterproof cement mortar leveling layer and foundation with dense, no hollowing, smooth surface, no cracks, from the sand, yin and yang angle made of circular arc.

We are specialized in the production and marketing of Waterproofing Materials and Machinery.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1993 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | South America; Asia; Africa; Mid East |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 20% - 50% |

| No.of Employees in Trade Department | 6-10 people |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 2000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | |

Send your message to us

Bitumen Roofing Felt

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 Square Meter m²

- Supply Capability:

- 300000 Square Meter per Month m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords