Polyurethane Waterproof Coating One/Two Component

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Component Polyurethane Waterproof Coating Introduction

Single-component moisture-curing pure polyurethane waterproof coating is a kind of liquid polymer waterproof material,

suitable for dry and wet base surface construction, solidified into tough and elastic, non-toxic and tasteless waterproof

film after coating. It is a new type of environmental friendly waterproof material without solvent.

Single Component Polyurethane Waterproof Coating Application

•Building roof

•Concrete

•Wall

•Water Tank Structure

•Floor(kitchen floor, bathroom floor ect)

•Underground Tunnel

•Sewerage Structure

•Movement Joint

•Wet Area, Pipes, Sewer & etc.

Single Component Polyurethane Waterproof Coating Advantage

1.water based and solvent based

2.Solid content above 80%

3.Durable performance, UV resistant, ageing-resistant,resistant high and low temperature,antifatigue, withstand constant immersion in water

4.Good splicing performance

5.Operate conveniently, low viscosity

6.Can splicing with concrete and many kinds board stuff

7.Will not change color after used

8.Apply for Roof,Swimming Pool,Tank and more

Single Component Polyurethane Waterproof Coating Specifications

NO. | Items | Ⅰ | Ⅱ |

1 | Tensile Strength MPa≥ | 1.9 | 2.45 |

2 | Elongation at Break %≥ | 550 | 450 |

3 | Tearing Strength N/mm≥ | 12 | 14 |

4 | Bend at Low Temperature°C≤ | -40 | |

5 | Unpermeability0.3MPa 30min | Impermeable | |

6 | Solids Content%≥ | 80 | |

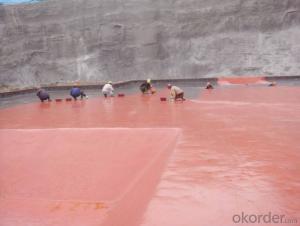

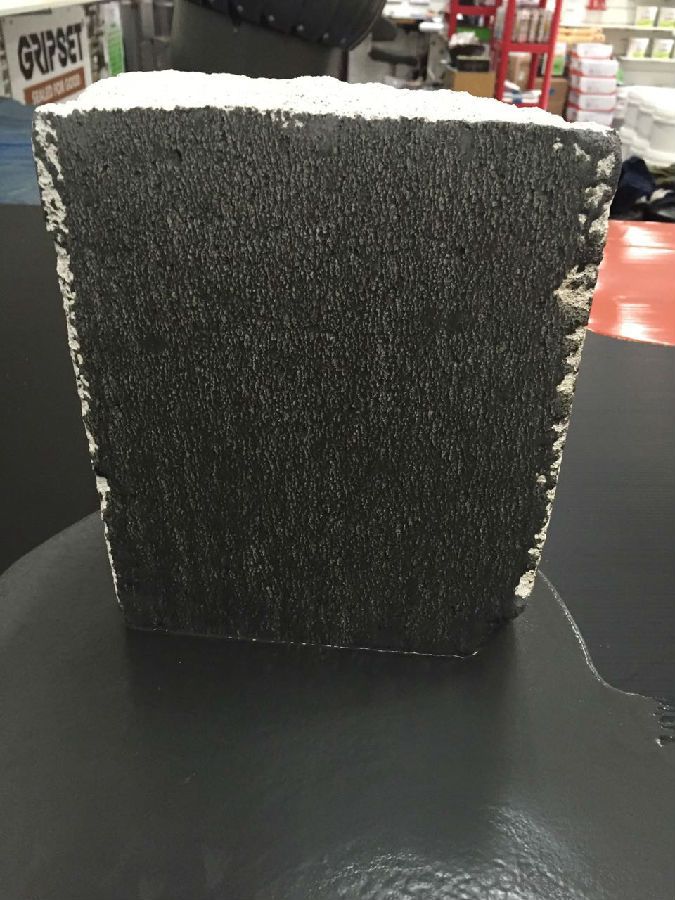

Single Component Polyurethane Waterproof Coating photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: Can acrylic materials be perforated? How to do waterproof after punching?

- Or in the back with glass adhesive paste anti-corrosion nine PCT board (if the hole is flat, Anti-corrosion nine PCT is to remove the other side of the paste surface with asphalt anti-corrosion paint brush)

- Q: Find the construction steps for waterproof coatings

- 1, base surface treatment (1) roof structure After the completion of concrete pouring, should be repeated water compaction, so that the surface of the grass-roots level, the flatness with 2m to check the ruler, ruler and grass-roots gap of not more than 5 mm, and only allow gentle changes. (2) the base surface of the pores, rugged, honeycomb, gap, sand, etc., should be promptly treated, the base surface must be clean, no floating slurry, no water beads, no water; when the base surface appears more than 0.3 mm cracks , Should rush each 10 cm brushing 1 mm thick polyurethane coating waterproof layer, and then set the polyurethane cloth reinforcement layer, and finally brushing waterproof layer. (3) all the corners are used 5 × 5㎝ 1: 2.5 cement mortar for chamfering, the angle made R = 10 mm rounded corners.

- Q: Do you use the waterproof material on the building to be harmful to the human body?

- Your pores, the respiratory tract, the lungs, will be hurt, when young do not feel out, the consequences more powerful than smoking.

- Q: Can Henkel have water against him?

- Add a small amount of water is possible because the premise of waterproofing should also be wet before the grassroots

- Q: Js waterproof coating without powder can brushing

- 4. Coating protection: JS waterproof coating after the end of the construction, not thoroughly dry before the need to protect the coating, including the suppression of pedestrians, rain erosion, exposure, sharp damage to objects; thoroughly dry solid JS cement Emulsion coating does not need to do other protective layer;

- Q: There is no formaldehyde in the finished putty

- Visible putty powder and formaldehyde or a great relationship, but now many manufacturers have introduced environmentally friendly putty powder, not only environmentally friendly pollution-free important is also can control the air, there is a negative ion putty powder is the composition which contains tourmaline tourmaline, through And the water molecules in the air combined with the decomposition of negative ions to deal with the air, anion can be neutralized with formaldehyde into dust falling into the air, you can also remove the dust in the air, as well as enhance the metabolism of the function.

- Q: FRP finished brush on what can be waterproof do not fade

- With glass fiber reinforced plastic + color paste even after the use of. Can be waterproof.

- Q: What should you pay attention to before the construction of the basement waterproofing membrane?

- Plastic runway construction should pay attention to: 1, before the construction, must be on the asphalt concrete foundation for quality acceptance, acceptance criteria according to design standards and technical specifications, the plastic runway in the corresponding drainage facilities, can be used around the clock. The ambient temperature should be controlled at 5 ℃ ~ 38 ℃, to avoid below 5 ℃, 38 ℃ above the ambient temperature operation, the relative humidity control below 70%, the foundation requires a clean, according to the temperature and relative humidity to adjust the amount of catalyst The curing speed control appropriate. Color paste and prepolymer storage, the lid to be tightened, before use to detect moisture, qualified after use, the water in the foundation should also be controlled to avoid the bubble after the glue. Plastic pavement materials must be carefully checked when the quality inspection certificate and validity period.

- Q: What are the materials used in the ceiling?

- Kitchen bathroom ceiling material 4: sauna board ????This is a dedicated wood panel for the sauna, but it can also be used in the kitchen and bathroom, generally degreased, with high temperature, not easy to deformation, health and environmental protection and other characteristics, even if there is a long time in the water Will not rot, usually painted in a layer of paint decoration, can make the overall ceiling more beautiful.

- Q: Waterproof material water leakage construction should pay attention to what

- 2, wall treatment · Wall treatment to do about 300mm high waterproof coating, to prevent water infiltration wall back tide. · Bathroom between the wall and the ground (plane and elevation) brushing height should be greater than 100mm. · The height of the shower room in the bathroom is not less than 1800mm. · If there is a bathtub, the height of the wall adjacent to the bathtub should be 300mm higher than that of the bathtub. · Waterproof height of tub is not less than 800mm. · The height of the squat should be more than 900mm. For the transformation of the toilet wall and self-built light wall, the proposed height of the waterproof to do the top.

Send your message to us

Polyurethane Waterproof Coating One/Two Component

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords