Bitumen Asphalt Roofing Felt For Waterproof Field

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 Square Meter m²

- Supply Capability:

- 300000 Square Meter per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

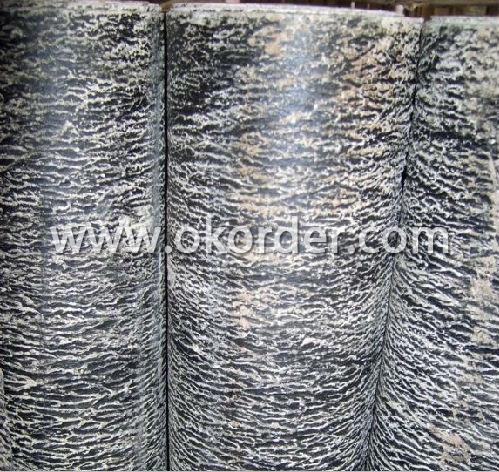

The roofing felt is widely used as underlayment which is under asphalt shingles. Its saturation rate is 100%,that’s to say, both water and air cannot enter.

Heavy-weight asphalt roofing felt made of a specially formulated organic sheet which has been fully saturated with waterproofing asphalt.

Asphalt roofing felt used as an underlay beneath asphalt shingles, wood shakes, tiles and other sloped coverings.

Detailed Specification of Roofing Felt:

Model | Width | Length | Thickness | Weight | Qty/pallet | Qty/40'GP |

ASTMD4869#15 | 36inch | 144feet | 0.5mm | 38lbs | 39rolls | 1560rolls |

ASTMD4869#30 | 36inch | 72feet | 0.7mm | 30lbs | 52rolls | 1924rolls |

ASTMD226 #15 | 36inch | 144feet | 0.7mm | 45lbs | 30rolls | 1110rolls |

ASTMD226 #30 | 36inch | 72feet | 1.2mm | 48lbs | 30rolls | 1110rolls |

- Q: Bathroom first leveling or do waterproof, what is the difference

- 7. The threshold stone is only decorated, do not mistakenly believe that can hold water. In short, each process have to carefully do not leave a hidden trouble to ensure worry. But the reality of the structure, materials, workers, mutual protection and many other unsatisfactory, so that waterproof is a common problem, perhaps set (overall) bathroom by the factory as a whole production test, on-site assembly will solve this common problem.

- Q: A complete set of basement waterproof construction program

- First, the basement of the external walls of water leakage project engineering basement waterproofing standard GB50108-2001 "underground engineering waterproof technical specifications" secondary waterproof rating. Basement exterior wall waterproof structure with self-waterproof concrete plus coil waterproof, 50 thick polystyrene board protective layer.

- Q: What is the car waterproof sticker material?

- Engraving process car sticks A. knife engraving process: refers to the computer will be vector graphics input knife machine, the knife will be cut into a preset film shape, and then by hand will be different colors together Finished, and finally in the finished product posted on the surface of a layer of transparent transfer film, after the stickers to remove the stickers; due to knife car paste production process is complex, high cost of materials, currently only suitable for individual car and Che Youhui team Small customization

- Q: Find the construction steps for waterproof coatings

- 2, waterproof layer construction sequence and methods (1) base surface treatment and acceptance of qualified, and now Yin, Yang angle and construction joints and other special parts brushing waterproof coating layer, strengthen the layer 1 mm, strengthen the layer after brushing, immediately paste fiberglass cloth or 30 ~ 40g / ㎡ polyester cloth reinforcement layer, is strictly prohibited to strengthen the surface layer and then paste the reinforcement layer material. (2) to strengthen the layer of hard work, began to brush a large waterproof layer, waterproof layer using multi-channel (3 to 5) brushing, brushing the upper and lower coating should be perpendicular to each other. When the surface of the coating is completely cured (not sticky hands) before the next curtain coating construction. (3) polyurethane coating waterproofing layer after the completion of the experience of acceptance, the timely application of the waterproof layer of the protective layer, the plane protective layer with 7 cm thick fine stone ㎝, in the pouring of fine stone before the need to cover the waterproof layer A layer of 350 # paper tire linoleum insulation layer. Facade waterproof layer (such as anti-beam facade) with a thick 6 mm polyethylene foam protection (expansion ratio of not more than 25 times).

- Q: Self-built concrete house finished three years after the use of large-scale housing wall leakage how to do?

- Second, the chisel in addition to the wall structure to the wall structure for waterproof construction, you can use the material coating, membrane and infiltration of crystallization, the quality is different.

- Q: There is no formaldehyde in the finished putty

- Visible putty powder and formaldehyde or a great relationship, but now many manufacturers have introduced environmentally friendly putty powder, not only environmentally friendly pollution-free important is also can control the air, there is a negative ion putty powder is the composition which contains tourmaline tourmaline, through And the water molecules in the air combined with the decomposition of negative ions to deal with the air, anion can be neutralized with formaldehyde into dust falling into the air, you can also remove the dust in the air, as well as enhance the metabolism of the function.

- Q: What should you pay attention to before the construction of the basement waterproofing membrane?

- 4, the preparation of finished products: according to the pavement area required to calculate the semi-finished products, the required slurry and prepolymer were lifted to the console, according to batch release neatly. Place the desired vinyl particles and catalyst into the appropriate position on the table.

- Q: How does the waterproofing membrane work?

- 5, lap seam treatment: the roll is rolled, the adjacent two webs of the joints with a short stove welding welding sticky, heated to spill hot melt adhesive for the degree, and then use the flame and iron wipe The sub-joints will be evenly heated to wipe the edge; 6, the coil side of the sealing side of the construction.

- Q: Waterproof material water leakage construction should pay attention to what

- Or to local, if it is a bathroom, it should pay attention to these points: Bathroom waterproof practice: 1, ground handling Before the water treatment, must first find the ground. Leveling layer of construction methods: the base surface with gaps, cracks, unequal defects, with cement mortar repair smooth. So that the base surface must be strong, smooth, clean, dust-free, greasy, wax, release agent, and other debris material. Leveling layer before drying can be waterproof construction, construction should be fire, waterproof. After the completion of the waterproof layer, to be finished product protection, not on the move.

- Q: What is the difference between finished mortar and cement mortar?

- Finished mortar is good, easy to mix, is conducive to the improvement of masonry and work efficiency; cement sand waterproof, suitable for wall paste wall, wall light

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 100 Million |

| Main Markets | America; Europe; Asia; the middle east |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 50% - 100% |

| No.of Employees in Trade Department | 6 - 10 people |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 20000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | |

Send your message to us

Bitumen Asphalt Roofing Felt For Waterproof Field

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 Square Meter m²

- Supply Capability:

- 300000 Square Meter per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords