Oil Christmas Tree of High Quality with API 6A Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Oil Christmas Tree Description

These units are used to control wellhead pressure and adjust oil/gas flowrate.

Structural models:single-wing or dual-wing;single-string or dual-string integrated.

The trees can be fitted with the hydraulic or pneumatic safety value and also with the control panel to implement remote control.

Type of choke value:fixed or adjustable.

2. Main Features of Oil Christmas Tree

• Consist of casing head, tubing head and Christmas tree.

• Apply to all kinds of casing, tubing programs and connection forms.

• Feature reliable running, simple and convenient operating and repairing.

• Can be equipped with (pneumatic) hydraulic safety valve.

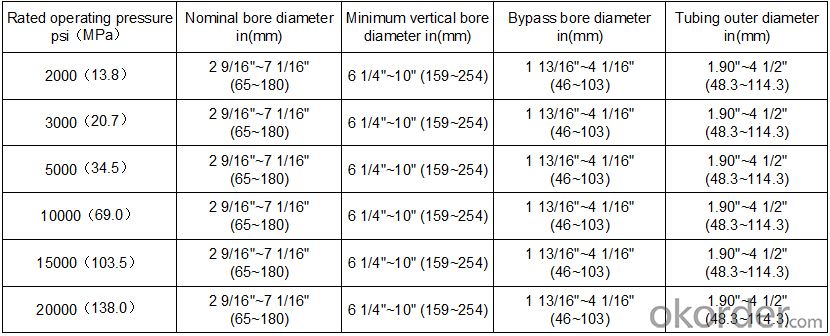

• Working pressure: 2000PSI~20000PSI

• Working medium: oil, natural gas, mud ,including H2S,CO2

• Working temperature: -46°C~121°C(Class LU)

• Material class: AA,BB,CC,DD,EE,FF

• Specification level: PSL 1-4

• Performance level: PR 1-2

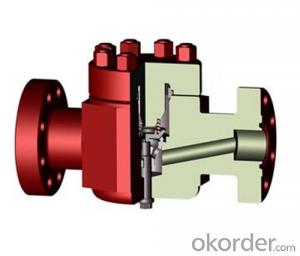

3. Oil Christmas Tree Images

4. Oil Christmas Tree Specification

5. FAQ of Oil Christmas Tree

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing Oilfield products in China, mainly offering various of oilfild products consists of our one-stop sales. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: Ive been tolding one or more of my valves is/are knocking, how can I fix this. Detail would be great, this is for a F0RD 460, from a 90. I was wondering if I can just buy some used heads(not sure if this comes with these things called valves, haha)but I can pick up some 460 heads, for pretty cheap.. on those and do a full swap, since mine is from 90 i dont know if year would matter. So how can I fix knocking valves., thanks

- Valve noise is usually caused by a bad hydraulic lifter, or a worn cam lobe, sometimes wear in the rocker arms also. I don't think changing the heads would help much in your case. I woud get a good mechanic to listen to it, and tell you first ok, because sometimes, just changing the oil and putting in an additive will stop noisy valves good luck

- Q: I am trying to replace a leaky valve stem. And I didn't know how to get to the valve core and when I get there how do I change it? The charge is recovered. It is a 2000 Impala. Thanks in advance.Noah

- Schrader Valve Core

- Q: The tricuspid valve is closed: a. during the rapid filling of the ventriclesb. when the mitral valve is openc. during ejection of blood from the ventriclesHelp plzThank you!

- c

- Q: My house has hot water baseboard heat. In the basement, there is a wood burning stove (now it is like a radiator) that has the pipe system going through it Between the pipe in and the pipe out is a valve. Does it have to be opened or closed all the way? There is no other way to control the heat in the basement I was thinking of opening the valve half way, but I do not want to destroy the valve.

- you have water baseboard pipe heat running through your Wood burning Fireplace? is that correct? At the end there is a valve? If so these two have no correlation with one another. Your water heating system is pumped through with a circulating pump and the temperature is controled by a thermostat. If If the house is hot then you have a thermostat problem OR there are zone valves located within the piping that opens and closes according to your thermostat setting. If you are not getting comfortable temps then check this little zone valve motor and replace. Just open all the baseboards covers until you locate a little zone valve motor valve. Change this out and see what happens.

- Q: Hi,I have just bought a Northface Hammerhead and for some reason when biting on the bite valve no water is being released. Does anyone have any idea why this might be, or can tell that I am missing something obvious. Thanks very very much.

- My the north face bite valve never worked either.

- Q: I want to reduce the prssure of a liquid flow (ethanol) from 16.7 atm to 1.2 atm? Do I need more than one valve?

- One control valve can reduce pressure, as long as there is always a significant flow through it. The main reason for using more than one valve is usually to reduce or prevent cavitation caused by a large pressure change through a given valve. Ethanol has a pretty high vapor pressure, so cavitation might be a problem. Control valve manufacturers usually provide design guides for their valve trim choices (often in software form) that lead you through the choices and requirements. Each valve design has different limits. But, my seat of the pants feel is that you can do this with one valve. I have included an example. I am not specifically recommending this company. -- Regards, John Popelish

- Q: Hi.. I was looking forward to install an electric supercharger for my 2 litre non turbo engine.This unit is driven by an electric motor instead of being mechanically driven.My question is if I can install a blow off valve in between the supercharger and the inlet manifold? Will it work?

- Hey guy. First off, you shouldn't even bother putting in an electric supercharger. The reasons are the about of boost you are going to need to see any REAL advantages you will not get from an elec. I suggest do what I am doing and spending the money to get a GOOD valve job and get everything polished to match and you will actually gain H.P. I have seen 32 hp gains out of a 2.2 I4 F2 engine from a probe by just adding a cold air intake, going to a 2 inch exhaust w/ header and a good valve job. Incidently, I now run 142 hp instead of the original 110.

- Q: Why do we use in chilled water pipe network utilizing 2 way valves on all terminals except the last terminal we use a 3 way valve, also another question what does a pump shutt off pressure means

- maybe so at the end of the line if it needed to be discharged in a different direction it could, or in case the other side was frozen or something...... and a pump shut off kills pressure,.

- Q: Is it hereditary? My dad had a bicuspid valve and we got told it was hereditary but some doctors say it's not, my parents wanted to get me tested in case i had it so we would know in advance but the doctors here refuse to do it (I live in England if that makes a difference) my dad said he would pay to go private if it's hereditary. I know someone who had a bicuspid valve and 3 out of her 4 children inherited it, i know it's pretty harmless until i reach an older age but my parents and i would like to know now, i'm 13 by the way.=]

- About 1-2% of the population have bicuspid aortic valves, although the condition is nearly twice as common in males. It is more common than any other congenital cardiac anomaly. Bicuspid aortic valve has been found to be an inheritable condition, with a demonstrated association with Notch 1. Familial clustering as well as isolated valve defects have been documented. The incidence of bicuspid aortic valve can be as high as 10% in families affected with the valve problem. Other congental heart defects are associated with bicuspid aortic valve at various frequencies.(Wikipedia) The cause of this problem is unclear, but it is the most common congenital heart disease. It often runs in families.(MedlinePlus)

- Q: is there any way to buy refills for empty valve oil bottles, such as holton or al cass

- Refills? okorder they are horrible!

Send your message to us

Oil Christmas Tree of High Quality with API 6A Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords