Nordic Ware Mill Finished Aluminum Sheet for Subway Cabin

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished Aluminium Sheet for Subway Cabin Description

Mill Finished Aluminium Sheet for Subway Cabin is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished Aluminium Sheet for Subway Cabinle

Mill Finished Aluminium Sheet for Subway Cabin | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished Aluminium Sheet for Subway Cabin

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished Aluminium Sheet for Subway Cabin

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished Aluminium Sheet for Subway Cabin

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

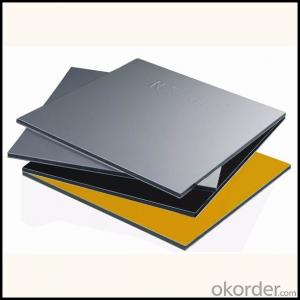

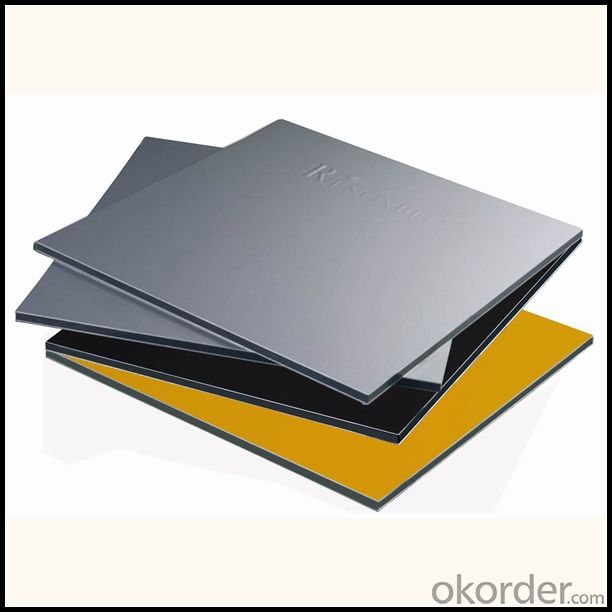

6. Image of Mill Finished Aluminium Sheet for Subway Cabin

7. Package and shipping of Mill Finished Aluminium Sheet for Subway Cabin

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks about the various colors and finishes that can be applied to aluminum sheets.

- <p>Aluminum sheets are available in a wide range of colors and finishes, offering versatility for various applications. Common colors include silver, white, black, and bronze, but they can also be anodized or painted to achieve virtually any color. Finishes can be smooth, brushed, or embossed, with options like matte, satin, and gloss. Additionally, there are specialty finishes like mirror-like polished, hammered, and wood grain textures. The choice of color and finish depends on the specific requirements of the project, such as aesthetics, durability, and resistance to environmental factors.</p>

- Q: My professor gave us the following:1roll of Reynonlds Wrap Heavy Duty Aluminum18.0 in wide, 500.0 ft long and 0.94mil thickThe cost $48.98and I'm not sure how to figure it out

- You have : ---------------- V = aluminum volume in one roll = ( L ) ( W ) ( t ) V = ( 500 ft ) ( 1.5 ft ) ( 0.94 mil ) ( 1 in / 1000 mil ) ( 1 ft/12 in ) V = 0.05875 ft^3 m = aluminum mass = ( d ) ( V ) m = ( 168 lbm/ft^3 ) ( 0.05875 ft^3 ) = 9.87 lbm m = ( 9.87 lbm ) ( 453.6 g / 1.0 lbm ) = 4477 g n = moles of aluminum in one roll = m / M n = ( 4477 g ) / ( 27 g/mol ) = 165.8 moles Al N Al atoms = ( n Al ) ( NAVO ) N Al atoms = ( 165.8 mol ) ( 6.022 x 10^23 atoms / mol ) N Al atoms = 998.5 x 10^23 Al atoms C* = cost per atom = cost of aluminum roll / number of aluminum atoms in one roll C* = ( 4898 cents ) / 998.5 x 10^23 atoms ) C* = 4.91 x 10^-23 cents per Al atom --------------- Please award Best Answer to the most correct and most helpful response to your question. C* =

- Q: Are the aluminum sheets suitable for manufacturing food processing equipment?

- Yes, aluminum sheets are suitable for manufacturing food processing equipment. Aluminum is a lightweight, durable, and corrosion-resistant material, making it ideal for use in the food industry. It is non-toxic, odourless, and does not affect the taste or quality of the food being processed. Additionally, aluminum is easy to clean and maintain, ensuring hygiene standards are met. Its ability to conduct heat efficiently also makes it suitable for applications such as cooking and baking. Overall, aluminum sheets are a popular choice for manufacturing food processing equipment due to their numerous beneficial properties.

- Q: Can aluminum sheets be custom cut to specific sizes?

- Yes, aluminum sheets can be custom cut to specific sizes according to the requirements of the project or application.

- Q: Are aluminum sheets suitable for use in HVAC (heating, ventilation, and air conditioning) systems?

- Aluminum sheets are indeed a fitting choice for HVAC systems. The popularity of aluminum in HVAC systems stems from its numerous advantageous properties. To begin, aluminum is both lightweight and robust, making it effortless to handle and install in HVAC systems. Its low density also enables cost-effective transportation and reduces the overall weight of the HVAC units. Furthermore, aluminum possesses exceptional resistance to corrosion. Given that HVAC systems often encounter moisture and condensation, particularly in air conditioning units, aluminum's corrosion resistance ensures its durability and longevity in such environments. Moreover, aluminum sheets exhibit commendable thermal conductivity, facilitating efficient heat transfer throughout the HVAC system. This property holds particular significance in heating and cooling applications, as it aids in effectively distributing the desired temperature. In addition, aluminum is a non-toxic material, rendering it safe for use in HVAC systems that circulate air within buildings. It does not emit any harmful particles or gases, thereby ensuring the quality of indoor air. Lastly, aluminum is highly recyclable, contributing to its environmental friendliness. The ability to recycle aluminum sheets reduces the carbon footprint associated with HVAC systems and aligns with sustainability objectives. Taking all these advantages into account, aluminum sheets undeniably prove suitable for use in HVAC systems. They offer an optimal combination of strength, corrosion resistance, thermal conductivity, safety, and environmental friendliness.

- Q: Is it suitable to use aluminum windows in areas with cold weather conditions?

- <p>Yes, you can use aluminum windows in cold climates, but there are considerations. Aluminum is a good conductor of heat, which can lead to heat loss in cold weather. To mitigate this, insulated glass units and thermally broken frames can be used. These designs slow down heat transfer, making aluminum windows more energy-efficient in cold climates. Additionally, proper sealing and weatherstripping are crucial to prevent drafts and ensure the windows perform well in low temperatures.</p>

- Q: Can the aluminum sheets be used for manufacturing musical instruments?

- Yes, aluminum sheets can be used for manufacturing musical instruments. Aluminum is a lightweight and versatile material that can be shaped and tuned to produce various musical sounds.

- Q: This question asks for a list of various methods used to treat the surface of aluminum sheets to improve their properties or appearance.

- <p>There are several types of surface treatment for aluminum sheets, each serving different purposes. These include: Anodizing, which creates a protective oxide layer and enhances corrosion resistance; Chemical Conversion Coating, such as chromate conversion, to improve paint adhesion and corrosion resistance; Electrolytic Polishing, which provides a smooth, shiny surface; Powder Coating, an electrostatic process that applies a durable coating; Paint Coating, offering a wide range of colors and finishes; and Mechanical Polishing, which smooths the surface and improves reflectivity. Each treatment has its specific applications and benefits, depending on the desired outcome for the aluminum sheet.</p>

- Q: I'd like to have the aluminum on the etching front white. Do any of the experts know that?

- After anodizing, it turns white. If not, the aluminum plate should be white and spray polyester or fluorocarbon paint,

- Q: I was quoted $5000+ to upgrade my house from 100A electric service to 400A. Part of the reason for the high cost is the cost of copper. What size copper wire is needed for 400A, and how much does it cost per foot? Would it be a lot cheaper to use aluminum wire?

- Aluminum has been outlawed due to corrosion issues. Actually, that is a good price. As for wire gage, 14-2 will be adequate, but when I did my house, I insisted upon 12-2 through out. It doesn't cost that much more and you will avoid the possibility of overheating or over load issues.

Send your message to us

Nordic Ware Mill Finished Aluminum Sheet for Subway Cabin

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords