China Aluminum Tin Sheets Mill Finished Aluminum Treadplate for Subway Tube

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished Aluminium Treadplate for Subway Tube Description

Mill Finished Aluminium Sheet for Subway Cabin is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished Aluminium Treadplate for Subway Tube

Mill Finished Aluminium Sheet for Subway Cabin | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished Aluminium Treadplate for Subway Tube

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished Aluminium Treadplate for Subway Tube

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished Aluminium Treadplate for Subway Tube

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

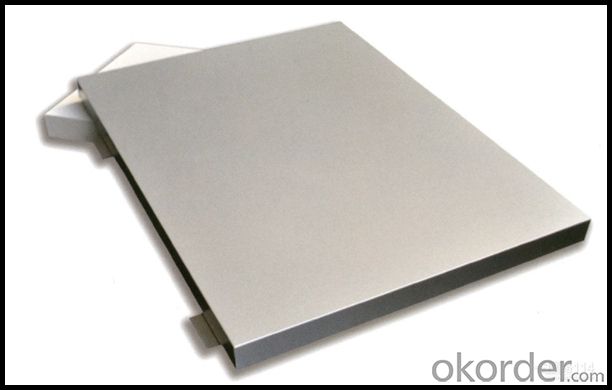

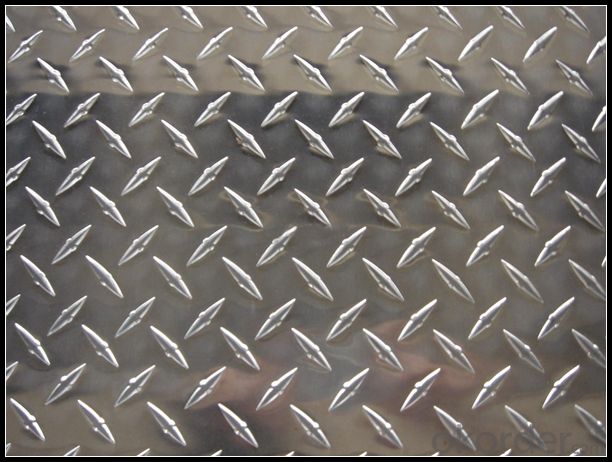

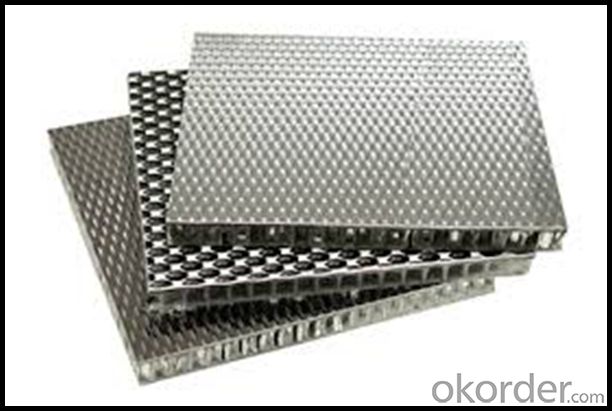

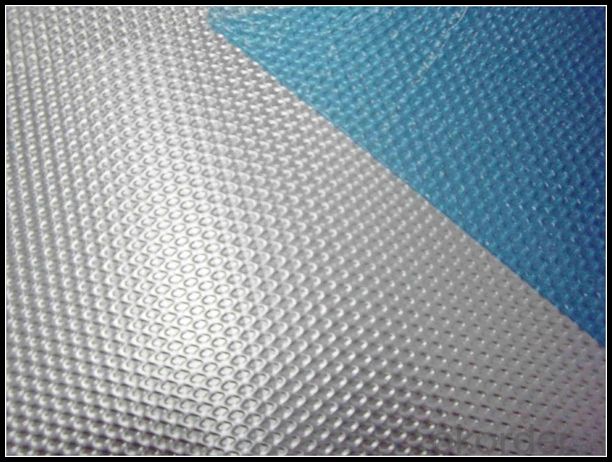

6. Image of Mill Finished Aluminium Treadplate for Subway Tube

7. Package and shipping of Mill Finished Aluminium Sheet for Subway Cabin

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks for a method to determine the quantity of aluminum sheets required for a specific project.

- <p>To calculate the amount of aluminum sheets needed for a project, first determine the area that needs to be covered. Measure the length and width of the surface in question. Multiply these two dimensions to get the total area in square units (e.g., square feet or square meters). Next, consider the thickness and specific requirements of the aluminum sheets, as this may affect the number of sheets needed. Finally, divide the total area by the coverage area of one aluminum sheet (which can be found from the supplier or calculated if you know the dimensions and thickness of a single sheet). Round up to the nearest whole number to ensure you have enough material for your project. Always account for waste and additional material for cuts or adjustments.</p>

- Q: What are the different types of finishes available for aluminum sheets?

- There are several different types of finishes that are commonly available for aluminum sheets. These finishes are applied to the surface of the aluminum to enhance its appearance, protect it from corrosion, and improve its durability. One of the most common types of finishes is the mill finish, which is the natural finish that is achieved after the aluminum has been extruded or rolled. This finish has a smooth and shiny appearance, but it is not as resistant to corrosion as some of the other finishes. Another type of finish is the brushed finish, which is achieved by brushing the surface of the aluminum with a fine abrasive material. This creates a pattern of fine lines on the surface, giving it a unique and textured appearance. Brushed finishes are commonly used in architectural applications and can also help to hide scratches and other imperfections. Anodizing is another popular finish for aluminum sheets. This process involves immersing the aluminum in an electrolytic bath and applying an electric current to it. This causes a layer of aluminum oxide to form on the surface, which provides excellent corrosion resistance and can be dyed in various colors for aesthetic purposes. Powder coating is another commonly used finish for aluminum sheets. In this process, a dry powder is sprayed onto the surface of the aluminum and then heated to form a durable coating. Powder coating is available in a wide range of colors and finishes, including matte, glossy, and textured. Finally, there is the painted finish, which involves applying a liquid paint to the surface of the aluminum. This finish offers a high level of customization, as it is available in virtually any color and can be applied in various patterns and textures. Overall, the choice of finish for aluminum sheets depends on the specific requirements of the application, such as aesthetics, corrosion resistance, and durability. Each finish offers its own unique advantages and can greatly enhance the appearance and performance of aluminum sheets.

- Q: This question asks for the method to determine the quantity of aluminum sheet required for a specific project.

- <p>To calculate the amount of aluminum sheet needed for a project, first determine the dimensions of the area to be covered. Measure the length and width to find the total area in square units. If the project involves complex shapes, break it down into simpler shapes like rectangles and circles, and calculate the area for each. Multiply the total area by the thickness of the aluminum sheet required. Finally, consider any additional material for overlaps or wastage, typically around 5-10%. The total volume calculated will give you the amount of aluminum sheet needed for the project.</p>

- Q: Are aluminum sheets suitable for chemical storage containers?

- Chemical storage containers are usually not appropriate for aluminum sheets. Despite aluminum's reputation for being resistant to corrosion, it can still interact with certain chemicals, causing the container to deteriorate and potentially contaminate the substance being stored. In addition, aluminum is a relatively fragile metal and may not offer sufficient strength and durability for the long-term storage of hazardous chemicals. It is recommended to utilize materials that are explicitly designed for chemical storage, such as high-density polyethylene (HDPE), polypropylene (PP), or stainless steel, as they provide exceptional resistance to chemicals and structural stability.

- Q: Are aluminum sheets suitable for cladding?

- Yes, aluminum sheets are suitable for cladding due to their durability, lightweight nature, and corrosion resistance. Additionally, aluminum offers versatility in terms of design options and ease of installation, making it a popular choice for cladding applications in various industries.

- Q: How does the thickness of aluminum sheet affect its strength?

- The thickness of an aluminum sheet directly affects its strength. Generally, thicker sheets tend to be stronger and more rigid due to the increased amount of material present. Thicker sheets are capable of withstanding higher loads and are less prone to bending or deformation under stress. However, it is important to note that other factors such as alloy composition and processing techniques also play a significant role in determining the overall strength of an aluminum sheet.

- Q: What are the standard sizes and availability of aluminum sheets in the market?

- The standard sizes and availability of aluminum sheets in the market can vary depending on the location and specific requirements. However, there are some commonly available sizes that can generally be found in most markets. In terms of thickness, aluminum sheets are commonly available in 0.02 to 0.2 inches (0.5 to 5 millimeters) thickness range. Thinner sheets (0.02 to 0.06 inches) are often used for lightweight applications such as signage or crafts, while thicker sheets (0.1 to 0.2 inches) are typically used for more heavy-duty applications like construction or industrial purposes. Regarding width and length, standard aluminum sheet sizes are often offered in 4 feet by 8 feet (48 inches by 96 inches) or 4 feet by 12 feet (48 inches by 144 inches). These dimensions are widely available and suitable for various applications. However, it's important to note that custom sizes can also be ordered or cut from larger sheets to meet specific project requirements. Availability of aluminum sheets can be found in various locations, including local hardware stores, metal suppliers, and online marketplaces. It is always recommended to check with local suppliers or conduct online research to determine the specific sizes and availability in your area. Additionally, different grades or alloys of aluminum may have varying availability, so it's essential to consider the specific requirements of your project when sourcing aluminum sheets.

- Q: Over 5 billion aluminum cans are recycled each year. If laid end to end, these cans would form a line reaching from?

- No, Ed. 1 billion seconds = 31.69 years, so it was the spring of 1976. Also 1 billion minutes ago = about 1901.3 years ago, so Christ would have been about 100. But I digress... Anyway, let's say the average aluminum can is 4.9 tall (I measured a Coke can). 5 billion cans would be 24.5 billion inches tall. This would be 386,679 miles. This would be from the Earth to the moon (about 250,000 miles) and halfway back again!

- Q: Can aluminum sheets be anodized for improved hardness?

- Yes, aluminum sheets can be anodized to significantly improve their hardness. Anodizing is an electrochemical process that thickens the natural oxide layer on the surface of the aluminum, creating a durable and corrosion-resistant coating. This process enhances the hardness and durability of the aluminum sheets, making them more resistant to wear, scratches, and other forms of damage.

- Q: My new home has a mix of copper and aluminum wiring. My mother used a shop vac in one of the recepticles last week and blew two of them in my bedroom. Then this weekend my brother was replacing my exhaust fan in the bathroom and that proceeded to blow the entire bedroom and bathroom including ceiling fans, lights and all recepticles. Does anyone have any ideas?

- Home Depot sells quality aluminium receptacles. Not doubting your father totally but an electrician needs to check the inside of the panel. A number of things can go and the breaker wont be effected. If the problem is not within the panel an electrician can trace the dead circuits and isolate the problems. Hopefully your new but old home does not have any concealed electrical boxes. Sometimes in older homes the previous owner may have added some electrical items and any Joe could have did it. Believe me I've seen a lot in my 15 years of practice.

Send your message to us

China Aluminum Tin Sheets Mill Finished Aluminum Treadplate for Subway Tube

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords