Aluminum Sheets Atlanta for Subway Cabin Flooring

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminium Treadplates for Subway Cabin Flooring Description

Aluminium Treadplates for Subway Cabin Flooring is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminium Treadplates for Subway Cabin Flooring

Aluminium Treadplates for Subway Cabin Flooring | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

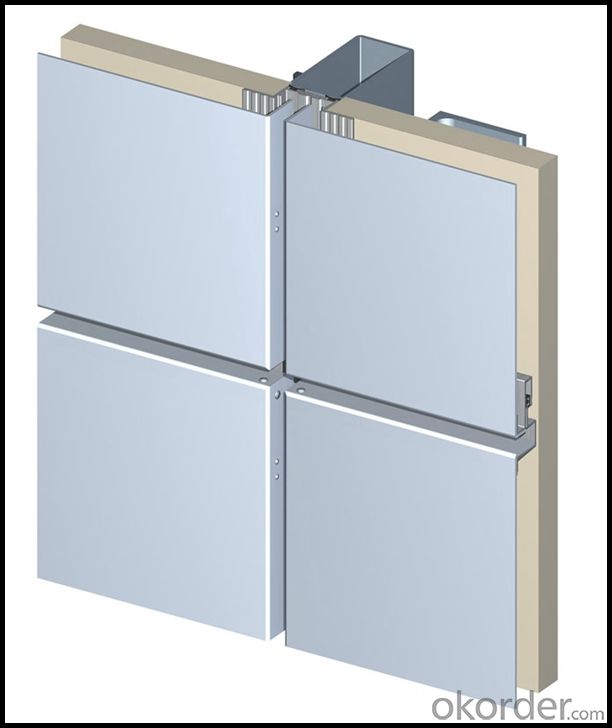

3. Application of Aluminium Treadplates for Subway Cabin Flooring

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminium Treadplates for Subway Cabin Flooring

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminium Treadplates for Subway Cabin Flooring

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

6. Image of Aluminium Treadplates for Subway Cabin Flooring

7. Package and shipping of Aluminium Treadplates for Subway Cabin Flooring

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks if there are any potential risks or hazards associated with using windows that are manufactured from recycled materials.

- <p>There are generally no significant safety concerns with using windows made from recycled materials. These windows are often made from recycled plastics or glass, which are processed to ensure they meet safety and quality standards. However, it's important to ensure that the recycled materials used are free from contaminants and are processed correctly to maintain structural integrity. Additionally, the manufacturing process should adhere to environmental and safety regulations to prevent any health or environmental risks. Always check for certifications and standards that the windows meet to ensure their safety and reliability.</p>

- Q: What is the thickness of the aluminum sheets?

- The thickness of the aluminum sheets can vary depending on the specific product or application. Aluminum sheets are available in a wide range of thicknesses, typically ranging from 0.006 inches (0.15 mm) to 0.25 inches (6.35 mm) or even thicker. The appropriate thickness will depend on the specific requirements and intended use of the aluminum sheet.

- Q: Everyone said that the pre roll coated aluminum plate, what is pre roll coating?

- Beforehand, beforehand, mean,Roll coating is a paint coating process, relative to spraying, such as powder, wall coating, coating or roller coatingThe coating is applied to the surface of the aluminum sheet by a roller or steel roller. Roll coating

- Q: This question asks for a comparison of various types of aluminum sheet materials, highlighting their unique characteristics and differences.

- <p>Aluminum sheet materials vary based on alloy composition, thickness, and surface treatment. Common types include 1000 series (99% pure aluminum), 3000 series (alloys like 3003 and 3004), 5000 series (magnesium alloys), and 6000 series (magnesium-silicon alloys). Each series has distinct properties: 1000 series is soft and ductile, 3000 series offers moderate strength and good formability, 5000 series has high strength and corrosion resistance, and 6000 series is known for its strength and excellent weldability. Thickness and temper (hardness) also affect performance, with thinner sheets being more flexible and harder tempers offering greater strength. Surface treatments like anodizing or painting can enhance appearance and corrosion resistance.</p>

- Q: What is the use?

- The three and 3000 series aluminum on behalf of 300330033A21. Also known as China's 3000 series aluminum antirust aluminum production process is more outstanding.3000 series aluminum is made of manganese as main components. The contents of 1.0-1.5 in between. Is a series of anti rust function better. Routine application in air conditioning, ice box, car etc. in the moist environment, price more than 1000 written columns, is a commonly used alloy series.The four and 4000 series aluminum aluminum on behalf of 4A014000 series belongs to the high silicon content series. Usually silicon content between 4.5-6.0%. Belongs to the building material, mechanical parts, forging materials, welding materials; low melting point, good corrosion resistance of the product description: has the characteristics of heat resistance, wear resistanceThe five and 5000 Series 5052.5005.5083.5A05 series.5000 series aluminum plate belongs to the representative of the more commonly used aluminium alloy series, the main elements of magnesium, magnesium content in 3-5%. Also called aluminum magnesium alloy. The main characteristics of low density, high tensile strength, elongation rate is high. In the same area under the weight of the aluminium magnesium alloy is lower than that of other series. It is commonly used in aviation, such as aircraft fuel tank. The application in the conventional industries are more widely. The processing technology for slab continuous casting and rolling, which belongs to the aluminum plate series so can do deep processing. Oxidation belongs to one of the more mature aluminum series in China 5000 series aluminum plate.

- Q: Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for various industrial applications, including shelving. It offers strength and stability while being easy to clean and maintain. Additionally, aluminum's versatility allows for customization and modification to fit specific storage needs.

- Q: I know aluminium forms a protective layer of aluminum oxide and hence water does not corrodes it easily.However, since the oxide is amphoteric, won't it react with acids and subsequently be dissolved?What is the main reason aluminium cans are used?

- Because of the aluminum chemical properties. Aluminum Oxide (Al2O3) is an extremely hard and compact material, so when the metal is exposed, it gets a very thin coat of Al2O3 that has a 9 hardness (only diamond is harder), that protects the rest of the metal from the atmosphere. Also, you should question if the phosphoric acid actually attacks aluminum, that is because that acid is found in Pepsi and coke..., BUT, as far as i know cans have a little plastic coat inside..., so the liquid does not get in touch with the aluminum.

- Q: What are the different surface patterns or textures available for aluminum sheets?

- Aluminum sheets come in various surface patterns and textures, each designed for specific purposes and offering unique aesthetic appeal. Some commonly used surface patterns for aluminum sheets are as follows: 1. Smooth: These sheets have a flat and polished surface without any visible patterns or textures. They are ideal for applications that require a clean and sleek appearance, such as architectural elements or interior design. 2. Diamond Plate: These sheets have a raised diamond pattern on the surface, providing excellent traction and slip resistance. They are commonly used for flooring, stairs, ramps, and industrial applications where grip and durability are essential. 3. Brushed: These sheets have a consistent linear pattern created by brushing the surface with fine abrasive pads. This finish gives a satin-like appearance, making it popular for decorative purposes like signs, furniture, appliances, and automotive trim. 4. Stucco: These sheets have a raised pattern that resembles a stucco wall finish. The texture is achieved by embossing the sheet with a stucco roller, creating a rough and durable surface. Stucco patterned sheets are commonly used for exterior cladding, roofing, and decorative applications. 5. Hammered: These sheets have a unique texture that resembles the surface of hammered metal. The finish is achieved by imprinting the sheet with a pattern of small indentations using a hammer or similar tool. Hammered sheets are often used for decorative purposes, such as backsplashes, countertops, and art installations. 6. Perforated: These sheets have a pattern of small holes punched into the surface, allowing for airflow, light transmission, and sound absorption. They are commonly used for architectural elements, screens, filters, and ventilation systems. These examples represent just a fraction of the surface patterns and textures available for aluminum sheets. Each texture serves a specific purpose and offers distinct visual appeal, enabling a wide range of applications in various industries.

- Q: Can aluminum sheet be used for electrical grounding applications?

- Indeed, aluminum sheet finds utility in electrical grounding applications. It possesses remarkable conductive properties, rendering it apt for employment in grounding systems. Its low resistance and exceptional electrical conductivity make it a common choice in diverse electrical applications. With the capability to proficiently transport electrical current and securely disperse it into the ground, aluminum sheet guarantees the safeguarding of electrical systems and averts potential electrical dangers. Moreover, the lightweight and corrosion-resistant attributes of aluminum establish it as a favored option for grounding applications across numerous industries, encompassing construction, automotive, and aerospace.

- Q: have been taking an over the counter Antacid consistently for the past 8 years as a daily source of extra calcium per the bottle. Now, I am getting many nerve problems, similar to Lou Gehrig's disease. I am a healthy 38 year old male who excersises, eats right and is generally health conscious. I am concerned that unknowingly I have toxified my body with the aluminum that apparently is in Antacid. I did not know this until now or of course I would not have gone any where near it.Can taking Antacid lead to nerve problems such as Lou Gehrig's disease?

- Aluminum okorder /

Send your message to us

Aluminum Sheets Atlanta for Subway Cabin Flooring

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords