Geotextil Tejido Precio Nonwoven Split Joint Fabric/Nonwoven Weed Barrier Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Weed Control Fabric Product Description

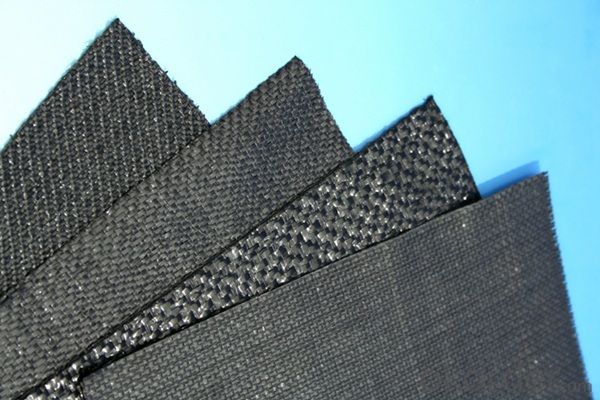

Weed Control Fabric is also known as weed control mat, anti grass cloth, ground cover, weed barrier, it is woven by polyethylene or polypropylene material. It is mainly used for ground weed prevention in the green house, drainage, maintain ground clean, ground mark and agricultural guidance, road surface protection and so on.

Weed Control Fabric Specification

Product Name | Weed Control Fabric |

Materials | 100% PP or 100% PE |

Weaved Condition | By circular jet loom or water looms |

Width | 0.5m to 6m (1.64ft to 19.69ft) |

Length | Made to the order (Customized available) |

Weight | 70g/m2 to 400g/m2 |

Mesh | 8x8; 10x10; 11x11; 12x12; 12x16; |

Colors | Black, Green, White etc. (Customized available) |

UV Protection | 2 years, 5 years, or more |

Application | Green House; Garden; Landscape; Road surface protection; Seedbed protection; Grass control etc |

Weed Control Fabirc Features

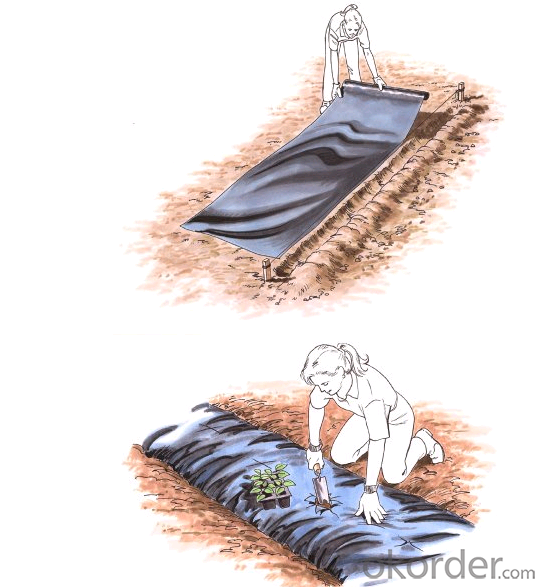

1. Weed suppressant and drainage control landscaping fabric

2. Easy to use, Environmentally friendly

3. Allows water, air and nutrients through, suppressing weeds without the use of chemicals

4. Reduces the level of watering required due to the slower rate of water evaporation

Weed Control Fabric Application

1. Excellent Weed Control

2. Moisture, fertilizers, air reach plants to allow for healthy soil

3. Good water and air permeability

4. Exceptional toughness and strength

5. Durable, tear-resistant; won't rot or mildew

6. Lightweight, easy to install, follows natural ground contours

7. Ideal for use in landscaped beds, under decks and walkways.

Packaging & Delivery

| Packaging Details: | Packed In Roll Or In Bales Or Cartons Or According To Customers Requirement |

| Delivery Detail: | 20 Days After Order Confirmed |

- Q: What is geomembrane geomembrane, composite geomembrane

- Anti-seepage drainage of the site ah Geomembrane ah

- Q: Geotextile manufacturers rely on what to do a hundred years do not rot geotextile

- Because geotextile raw materials are chemical fiber. Huazhi geotextile material answer

- Q: How do geotextiles aid in the filtration of water?

- Geotextiles aid in the filtration of water by acting as a barrier that allows water to pass through while trapping and filtering out sediment, dirt, and other contaminants. They help to prevent clogging and maintain the permeability of soil, improving the overall quality of water that passes through them.

- Q: Can geotextiles be used in green roof systems?

- Yes, geotextiles can be used in green roof systems. Geotextiles are often used as a separation layer between the growing media and the drainage layer in green roof systems. They help to prevent the mixing of different layers, while still allowing water to drain through. Additionally, geotextiles can also be used to reinforce the root barrier in green roof systems, providing added stability and protection.

- Q: How do geotextiles help with reinforcement of geotextile tubes?

- Geotextiles help with the reinforcement of geotextile tubes by providing strength, stability, and durability to the structure. They act as a barrier against soil erosion and provide a layer of protection for the geotextile tube. Additionally, geotextiles distribute the stresses evenly throughout the structure, improving its load-bearing capacity and preventing potential failures.

- Q: Garage top back to the soil before the drainage board geotextile take what role

- The top surface of the drainage board glue a layer of geotextile filter to prevent the passage of soil particles, so as to avoid drainage channel obstruction of the drainage channel, said white is to do a filter layer, the water discharged to the designated location, the traditional process is Block ah, stone ah, what do the water layer, and now with the drainage board is not the reason for the stone is the drainage board is plastic, light weight, can reduce the load of the building. Manufacturers of drainage board geotextile waterproof board

- Q: What are the factors to consider when selecting geotextiles for embankment stabilization?

- When selecting geotextiles for embankment stabilization, there are several important factors to consider. These include the strength and durability of the geotextile, its filtration and drainage properties, its compatibility with the soil and other materials, and its ability to withstand environmental conditions such as UV exposure and chemical exposure. Additionally, factors such as cost, installation requirements, and project-specific needs should also be taken into account.

- Q: How do geotextiles help with groundwater protection?

- Geotextiles function as a barrier or filter that helps protect groundwater by preventing the infiltration of contaminants into the underground water sources. They aid in separating different layers of soil and preventing the mixing of pollutants with the groundwater, thereby safeguarding the quality and purity of water resources.

- Q: Why the durability of filament geotextile is relatively strong

- The reason for raw materials

- Q: Waterproof and protective layer between which type of geotextile isolation layer

- Personally think to take impervious geotextile. Anti-seepage geotextile has excellent water permeability, filterability, durability, can be widely used in railways, highways, sports museum, dams, hydraulic construction, then hole, coastal beach, reclamation, environmental protection and other projects. Mainly staple acupuncture non-woven geotextile and split film woven geotextile. Check the original post & gt; & gt; trouble to adopt, thank you!

Send your message to us

Geotextil Tejido Precio Nonwoven Split Joint Fabric/Nonwoven Weed Barrier Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords