Bidim Geotextile Non Woven Needle Punch Geotextiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Geotextile

Good flexibility, permeability, filtration, sepatation and easy for construction.

Product Application

CMAX Geotextile has excellent permeability, acquired, durablity, which can be widely used in railway, highway, movement hall, dams, hydraulic structures, hence hole, coastal shoal,reclamation, environmental protection and other projects.

The main products are Synthetic staple fibers needlepunched non woven geotextiles and slit and split film yarn woven geotextiles.

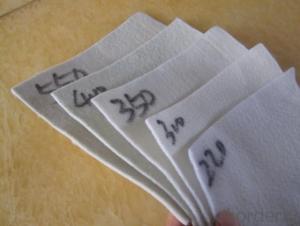

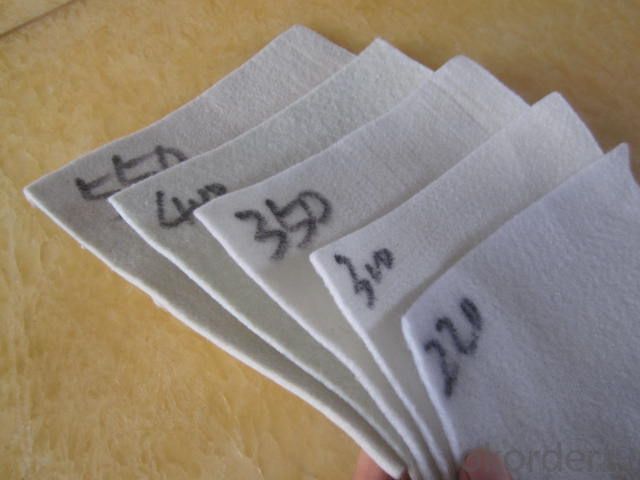

Product Specifications:

Weight: 100GSM-1500GSM

length: 50m-100m

width:1m-8m

material:100%PET

Packaging Details:pp woven bags or at your request

Delivery Detail:15 days

Product Property:

1. Super high strength, ultralight, high resistance.

2. Resistance to chemical erosion, excellent water resistance.

3. Abrasion resistant.

4. Excellent anti-aging and anti-UV property, good weather fastness.

FAQ:

Q: What kind of payments could you support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: In the river within the construction of flexible piping can use geotextile to do anti-floating measures

- Yes, I am specialized in producing the installation

- Q: How do geotextiles improve the performance of slopes?

- Geotextiles improve the performance of slopes by providing erosion control, stabilization, and reinforcement. These synthetic fabrics are installed between the soil layers of the slope, acting as a barrier to prevent soil movement and erosion caused by water flow or wind. Geotextiles also enhance the overall stability of the slope by improving soil drainage, reducing pore water pressure, and increasing soil strength.

- Q: Are geotextiles suitable for use in road shoulder stabilization?

- Yes, geotextiles are suitable for use in road shoulder stabilization. Geotextiles can effectively prevent erosion, improve soil stability, and provide reinforcement to road shoulders by distributing load and reducing lateral movement. They are also permeable, allowing for drainage and preventing water accumulation, which helps maintain the integrity of the road shoulder.

- Q: What are the factors to consider when selecting a geotextile for a specific application?

- When selecting a geotextile for a specific application, several factors need to be considered. These include the desired function of the geotextile, such as separation, filtration, drainage, reinforcement, or erosion control. The site conditions, including soil type, slope, and climate, also play a crucial role in determining the appropriate geotextile. Other factors to consider include the expected loads and stresses, installation requirements, longevity, and cost-effectiveness. It is important to consult with an experienced geotechnical engineer or geotextile specialist to ensure the right selection for the specific application.

- Q: Geotextile how to do on-site measurement

- Geotextile is calculated by the square, you only need to measure a long, wide, calculate the area will be able to know how much geotextile, and hope to help you!

- Q: How do geotextiles aid in the reduction of differential settlement?

- Geotextiles aid in the reduction of differential settlement by providing a stable and uniform foundation for the soil. They distribute and equalize the load across the soil, preventing differential settlement and ensuring the overall stability of the structure. Additionally, geotextiles can help in reinforcing weak soils, improving their bearing capacity and reducing the potential for differential settlement.

- Q: Can geotextiles be used in coastal erosion control?

- Yes, geotextiles can be used in coastal erosion control. Geotextiles are permeable fabrics that can be placed in coastal areas to stabilize soil and prevent erosion caused by waves and currents. They help to retain sediment and protect shorelines from erosion by absorbing and dissipating wave energy. Additionally, geotextiles can promote the growth of vegetation, further enhancing their effectiveness in coastal erosion control.

- Q: How long do geotextiles last?

- Geotextiles typically have a lifespan of 20 to 50 years, depending on factors such as the type of material used, environmental conditions, and the intensity of use.

- Q: What kind of geotextile is used to repair the road?

- Geotextile in the application of the road: a slope care, specifications in the 250-350g / m2 its role has the following three points: 1. filter when the water from the fine soil into the coarse soil layer, the use of polyester staple fiber Acupuncture geotextile good permeability and water permeability, so that water through, and effectively carrying soil particles, sand, small stone, etc., in order to maintain the stability of soil and water engineering. 2. Drain polyester staple fiber geotextile has a good water conductivity, it can form a drainage channel within the soil, the soil structure of excess liquid and gas efflux. 3. Protection of water flow on the soil erosion, the effective concentration of concentrated diffusion, transmission or decomposition, to prevent the soil by external forces and damage. Second, the foundation treatment, the main role is to strengthen. The use of polyester staple acupuncture geotextile to enhance the soil tensile strength and resistance to deformation, enhance the stability of the building structure to improve soil quality. Specifications not low 400g / m2. The main role is to use the polyester staple fiber geotextile with different physical properties (particle size, distribution, consistency and density, etc.) of the building materials (such as soil and sand, soil and concrete, etc.) ) To isolate. So that two or more materials are not lost, not mixed, to maintain the overall structure and function of the material, so that the building capacity to enhance the capacity. Specifications in the 150-400g / m2

- Q: How do geotextiles improve the stability of slopes?

- Geotextiles improve the stability of slopes by providing reinforcement and erosion control. They are placed within the slope to enhance its strength, prevent soil erosion, and increase overall stability. The geotextiles act as a barrier, distributing the forces exerted on the slope and reducing the potential for sliding or failure. Additionally, they can promote water drainage, preventing the accumulation of excess water that may weaken the slope. Overall, geotextiles play a crucial role in enhancing the stability and longevity of slopes.

Send your message to us

Bidim Geotextile Non Woven Needle Punch Geotextiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords