Vlies Geotextil Non-Woven Geotextile High-Performance for Highway, Railway, Dam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

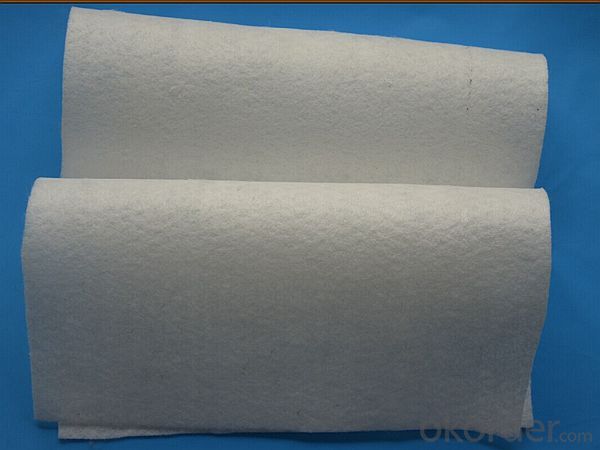

Thermal bonded Non-Woven geotextile

Non Woven Geotextiles

Non woven Geotextiles Fabrics are probably the most commonly known geotextiles. Nonwoven

polypropylene fabric, which has a felt-like consistency, combines strength and watr flow.

Available in varying weights and thicknesses, the fabrics are strong but permeable,

allowing for varied uses. Nonwoven fabrics commonly are used as a separator between

subsoils and rock riprap, and they also are used to separate soils and sized stone in many

ground-level and subsurface drainage applications. Nonwoven Geotextile Fabrics have a

random, three dimensional pore structure and are highly water permeable, as is necessary

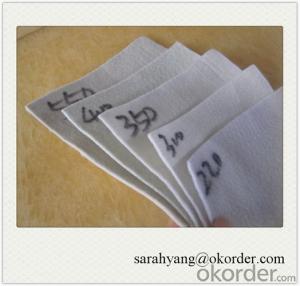

in many geotextile end uses. A wide range of fabric weights ranging from 3.1oz. to over 16

oz. is offered to meet the requirements of various Non-woven applications. Custom sizes

are available with all of our Woven and Non Woven Geotextile Fabrics. We offer the lighter

weight Non wovens fabrics in 3' X 300' and 3' X 360' rolls for use as Pipe Wrap. Below are

our standard weights and sizes.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FQR

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: Can geotextiles be used in land reclamation projects?

- Yes, geotextiles can be used in land reclamation projects. Geotextiles are commonly used in these projects to stabilize and reinforce soil, control erosion, and promote vegetation growth, ultimately enhancing the overall success and durability of the reclaimed land.

- Q: What are the different factors to consider for geotextile selection in agricultural applications?

- When selecting geotextiles for agricultural applications, several factors need to be considered. These factors include the type and level of soil erosion, the desired drainage and filtration requirements, the expected load and stress levels on the geotextile, the potential for chemical exposure, the climate and weather conditions, and the longevity and durability needed for the specific agricultural application.

- Q: How do geotextiles help in the reinforcement of soil?

- Geotextiles help in the reinforcement of soil by providing stability and strength to the soil structure. They act as a barrier between different soil layers, preventing their mixing and maintaining their integrity. Geotextiles also distribute the load evenly across the soil, reducing the risk of settlement or subsidence. Additionally, they improve drainage and filtration by allowing water to pass through while preventing the loss of fine particles. Overall, geotextiles enhance the overall performance and longevity of soil in various engineering and construction applications.

- Q: Can geotextiles be used in geosynthetic clay liners?

- Yes, geotextiles can be used in geosynthetic clay liners. Geotextiles are often used as a protective layer or separator between the clay liner and other materials in order to enhance the performance and longevity of the geosynthetic clay liner system.

- Q: How to deal with the use of geotextiles under the roof

- Use a drainage board

- Q: What are the standards and specifications for geotextiles?

- The standards and specifications for geotextiles are defined by various organizations such as the American Society for Testing and Materials (ASTM), the International Organization for Standardization (ISO), and the Geosynthetic Institute (GSI). These standards cover aspects such as tensile strength, elongation, thickness, permeability, and durability of geotextiles. They also provide guidelines for testing methods, installation practices, and performance requirements to ensure the quality and effectiveness of geotextile products in various applications like soil stabilization, drainage, erosion control, and filtration.

- Q: Construction of composite geotextile

- Geotextile as a protective layer of geomembrane, so that the protection of impermeable layer from damage. In order to reduce the UV radiation, increase the anti-aging properties, it is best to use the laying method. Construction, the first use of smaller diameter sand or clay to find the base surface, and then laying geomembrane. Geomembrane should not be stretched too tight, buried at both ends of the soil part of the corrugated, and finally in the shop on the geomembrane with a fine sand or clay shop layer of 10cm or so excessive layer. Puzzle 20-30cm stone (or concrete prefabricated block) for the anti-Chong protective layer. Construction, should try to avoid the stones directly hit the geomembrane, the best side of the film side of the protective layer of the construction. Composite geomembrane and the surrounding structure should be connected with expansion bolts and steel plate pressure bar anchorage, the connection site to brush the emulsion asphalt (2mm thick) bonding, to prevent the occurrence of leakage.

- Q: What are the advantages of using geotextiles in agriculture?

- Geotextiles offer several advantages in agriculture, including erosion control, weed suppression, moisture conservation, and improved soil condition. They prevent soil erosion by stabilizing slopes and preventing sediment runoff, ensuring the longevity of cultivated areas. Geotextiles also act as a barrier to weed growth, reducing the need for herbicides and manual weeding. Additionally, they aid in conserving moisture by reducing evaporation and maintaining soil moisture levels. Furthermore, geotextiles promote better soil structure and fertility by preventing soil compaction, improving aeration, and facilitating nutrient absorption.

- Q: You produce 700 grams of high-strength polypropylene geotextile it?

- 700 grams of high-strength polypropylene geotextile is designed for high-speed rail sliding layer of high-strength wear-resistant geotextile, our products in the West high-speed rail passenger line, OKorder and Hangzhou and other high-speed rail lines have applications.

- Q: How do geotextiles improve the performance of tunnels?

- Geotextiles improve the performance of tunnels by providing reinforcement and stabilization to the surrounding soil, preventing soil erosion and subsidence. They also act as a barrier to prevent the migration of fine particles, improving the overall durability and longevity of the tunnel structure.

Send your message to us

Vlies Geotextil Non-Woven Geotextile High-Performance for Highway, Railway, Dam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords