Geotextile 50m2 Non Woven Geotextile Fabric for Reinforcement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Key Specifications/Special Features:

Specifications

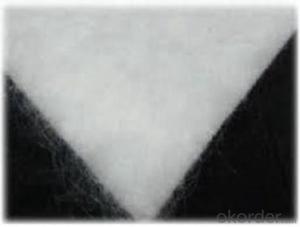

1) PET geotextile: non woven geotextile

2) Material: PP (polypropylene) or Polyester fibers

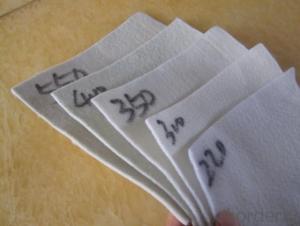

3) 100g/sq.m-1000g/sq.m

4) Width: 2m-6.5m

Non woven - needle punched, cut fibers geotextiles for protection, filtration, separation, drainage or reinforcement applications (see also woven Geotextiles and Geogrids)

Geotextiles made of virgin Polypropylene PP, Polyester PES

Under request, the geotextile is produced with black carbon to protect from UV

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the benefits of using geotextiles in construction projects?

- Geotextiles offer several benefits in construction projects. Firstly, they provide effective erosion control by stabilizing soil and preventing sediment movement, helping to maintain the integrity of embankments and slopes. Additionally, geotextiles act as a barrier against weed growth, minimizing maintenance efforts. They also enhance drainage and filtration systems, improving the overall performance of infrastructure projects. Furthermore, geotextiles can be used as reinforcement materials, providing strength and stability to various construction components like roads, retaining walls, and foundations. Overall, the use of geotextiles in construction projects offers cost-effective and environmentally friendly solutions for a range of engineering challenges.

- Q: Concrete panel shop asphalt do not add geotextiles

- Plus no geotextile cloth according to the design requirements and construction specifications. Generally require high road construction need to lay geotextile. Geotextile manufacturers to answer your questions

- Q: How do geotextiles contribute to the durability of civil engineering structures?

- Geotextiles contribute to the durability of civil engineering structures by providing reinforcement, filtration, and separation. They act as a barrier against soil erosion, increase the load-bearing capacity of soil, and offer protection against water seepage. These functions help to prevent structural damage, enhance the lifespan of the infrastructure, and ensure its long-term stability.

- Q: Can geotextiles be used in the construction of golf course bunkers?

- Yes, geotextiles can be used in the construction of golf course bunkers. Geotextiles are commonly used in construction projects to stabilize and reinforce soil. In the case of golf course bunkers, geotextiles can be used to prevent erosion, improve drainage, and provide a stable base for the sand.

- Q: The amount of geotextile drainage of the drainage pipe, as well as the amount of gravel block ye count

- Are you talking about plastic blinds? do you need? I specialize in producing geotextile materials

- Q: What is the size of the filament geotextile? What are the characteristics of the application?

- What is the size of the filament geotextile? What are the characteristics of the application?

- Q: Precautions for Polyester Filament Geotextiles

- Geotextile storage to meet the following requirements: the Treasury clean no debris, no chemical corrosion; not sun, tarnished; not weight, not scratch, to prevent violent collision; away from the hot source; dry and cool warehouse; There is a need for fire tools, fire hydrants, fire extinguishers and so on. Geotextile transport, loading and unloading requirements: can not be mixed with sharp items; hoisting with flexible rope; can not use steel wire rope directly hoisting; not with sticks, iron bars and other hardware auxiliary top loading; Stress dispersion measures, to avoid tightly tightened with a rope.

- Q: Are geotextiles environmentally friendly?

- Yes, geotextiles are environmentally friendly. They are made from natural or synthetic fibers that are biodegradable and do not release harmful substances into the environment. Geotextiles also help to prevent soil erosion, promote vegetation growth, and improve water quality, making them a sustainable solution for various environmental applications.

- Q: What are the maintenance requirements for geotextile installations?

- The maintenance requirements for geotextile installations typically involve regular inspections to ensure proper functioning and longevity. This may include removing any accumulated debris or sediment that could hinder its performance, checking for any signs of damage or wear, and addressing any issues promptly to prevent further deterioration. Additionally, periodic testing and evaluation of the geotextile's performance may be necessary to ensure it is meeting the desired objectives.

- Q: How do geotextiles help with moisture management in construction projects?

- Geotextiles aid in moisture management in construction projects by acting as a barrier against water infiltration and promoting drainage. They are permeable fabrics that allow water to flow through, preventing water buildup and potential damage to structures. Geotextiles also help to stabilize soil, control erosion, and separate different soil layers, further enhancing moisture management in construction projects.

Send your message to us

Geotextile 50m2 Non Woven Geotextile Fabric for Reinforcement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords