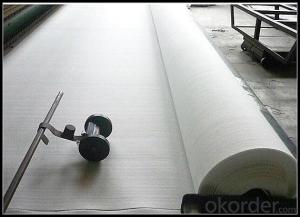

Geotextile Matt Non-Woven Geotextile Fabric for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products description:

The raw materials of geotextile are PET staple fibre, synthetic staple fibres, polypropylene ect. According to raw

material composition, the products are classified into 4 types : the same material and the same specification, the

same material and different specifications, different materials and the same specification, the different materials and different specifications. We can also produce it with imported materials.

Product Features

1. Geotextile has good air and water permeability to let water flow through it so as to effectively control

sandrock running-down.

2. Geotextile has good water transmissibility, it can form drainage channels inside soil mass to drain redundant liquid and air out of the soil mass.

3. Geotextile helps to enhance the soil mass' tensile strength and non-deformability and structural stability so as to improve soil mass quality.

4. It can effectively make the concentrated stress diffuse, transfer or decompound, and prevent the soil mass against the destruction of outside force.

5. It can prevent the mixture of sandstone, soil mass and concrete of upper and lower layers.

6. Its mesh is hard to jam by virtue of the compliancy and motility of the reticulation formed by indefinite form

fibrous tissue.

7. High water permeability-it can keep good water permeability even in the pressure of soil and water.

8. Corrosion resistant-it is made from polypropylene fiber or terylene or other chemical fiber, featuring resistance to acid and alkali

and oxidation, non-corroding, no worm-eaten.

9. Easy construction-low weight, easy operation, simple construction.

Specification:

Width: 1.0-4.0m (according to requirement)

Weight: 50g-800g for per square meter

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Geotextile detection sampling, how many meters

- Two meters by two meters! Geotextile manufacturers to answer!

- Q: Geosynthetics direct shear instrument reference standards which

- Geosynthetics Direct shear test The abrasive characteristics of the sand / geotextile interface were measured by direct shear test of the standard sand / geotextile contact surface. Test Specimens: 1. Tile the specimen on a rigid horizontal base located in the lower part of the shear box, with the front end of the specimen, and the test leads: ISO.1, GB / T.1, ASTM / D5321, JTGE50T1129, SL / T235-1999. Clamped in front of the shear zone, the sample and the base between the adhesive with adhesive, after bonding the sample should be flat, without folding and folding, the test sample and the base is not allowed between the relative slip; 2. Install the upper shear box: with the pre-quasi-quality standard sand filled with the upper shear box, the thickness of 50mm, sand thickness should be uniform, after the density of the density of 1750kg / m3; 3. Install the horizontal loader , And apply 50KPa to the sample with a reference weight of 50KPa normal pressure.

- Q: How do geotextiles help in preventing soil contamination from chemicals?

- Geotextiles act as a protective barrier between the soil and chemicals by preventing their infiltration into the ground. They effectively filter and separate contaminants, allowing water to flow through while retaining harmful substances. This helps in minimizing soil contamination and preserving its quality.

- Q: Can geotextiles be used in green wall construction?

- Yes, geotextiles can be used in green wall construction. They are often used as a base material to provide stability, drainage, and erosion control in green wall systems. Geotextiles help to retain soil and allow water to pass through, promoting healthy plant growth and preventing water buildup.

- Q: What are the advantages of using geotextiles in green roof design?

- Geotextiles offer several advantages in green roof design. Firstly, they provide an effective separation layer between the growing media and the roof membrane, preventing soil erosion and protecting the waterproofing layer. Secondly, geotextiles enhance drainage by allowing excess water to pass through the growing media and into the drainage layer, preventing waterlogging and maintaining a healthy environment for plant growth. Additionally, geotextiles can act as a filtration layer, preventing fine particles from clogging the drainage system and maintaining its functionality. Overall, the use of geotextiles in green roof design improves the longevity and performance of the roof system, while also aiding in stormwater management and plant health.

- Q: Can geotextiles be used for reinforcement of canal banks?

- Yes, geotextiles can be used for reinforcement of canal banks. Geotextiles are commonly employed in civil engineering projects to enhance the stability and strength of soil and structures. In the case of canal banks, geotextiles can be used to control soil erosion, improve drainage, and provide reinforcement against potential slope failures. They are effective in distributing loads, reducing soil movement, and preventing the loss of fine particles, which ultimately helps in maintaining the integrity and stability of canal banks.

- Q: What are the geotechnical test test items for highway engineering? The

- Unit area weight or tensile strength, CBR burst strength, these two are the most basic, the other is not too important

- Q: How do geotextiles help in preventing soil liquefaction?

- Geotextiles help in preventing soil liquefaction by providing stability and reinforcement to the soil. They act as a barrier and restrict the movement of soil particles, thereby reducing the potential for liquefaction. Additionally, geotextiles enhance the drainage capacity of the soil, allowing water to flow through and preventing the buildup of excess pore pressure, which is a major factor leading to liquefaction.

- Q: What are the advantages of using geotextiles over traditional construction materials?

- There are several advantages of using geotextiles over traditional construction materials. Firstly, geotextiles are lightweight and flexible, making them easier to handle and install compared to heavy materials like concrete or steel. Secondly, geotextiles have a high strength-to-weight ratio, providing excellent reinforcement and stabilization capabilities for soil and other materials. Additionally, geotextiles are permeable, allowing for proper drainage and preventing water buildup, which can lead to erosion or structural damage. Moreover, geotextiles are resistant to biological degradation, chemicals, and UV radiation, ensuring their long-term durability. Lastly, geotextiles are cost-effective, as they require less labor and equipment for installation and maintenance compared to traditional materials. Overall, the use of geotextiles offers numerous benefits in terms of efficiency, functionality, and sustainability in construction projects.

- Q: How do geotextiles improve the performance of geomembranes?

- Geotextiles improve the performance of geomembranes by providing additional support, protection, and filtration capabilities. They act as a cushioning layer, reducing the stress on the geomembrane and enhancing its durability. Geotextiles also prevent punctures and abrasion, acting as a barrier against sharp objects and protecting the geomembrane from damage. Moreover, they allow for drainage and filtration, ensuring proper water flow and preventing the buildup of pressure behind the geomembrane. Overall, geotextiles enhance the performance and lifespan of geomembranes by providing added strength, protection, and functionality.

Send your message to us

Geotextile Matt Non-Woven Geotextile Fabric for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords