Non-Woven Polypropylene Geotextile Fabric Reinforcement Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Polyester Nonwoven Geotextile:

The non woven geotextiles are made by non-woven process technology, selects polyester staple fiber with high monofilament strength and excellent thickness ratio as raw material after underwent adequate scutching.

The state-of-the-art high speed needle punching production line is adopted, its roll width is up to 8meters.

Main Features of Polyester Nonwoven Geotextile:

It is of excellent physical and hydraulic properties, and especially its advantages in the tensile strength,

longitudinal and lateral strength ratio, uniformity and so on.

Supply a wide range of color, such as white, green and grey. Independent developed soft green fiber can

protect installer’s eyes at the onsite during work under the strong light, and it is eco-friendly productions.

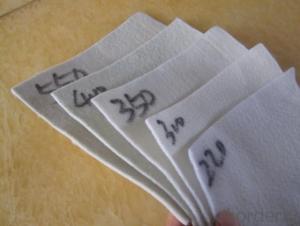

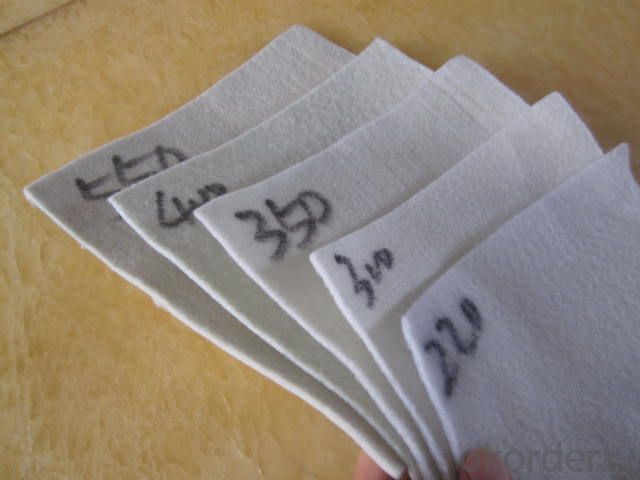

Specifications of Polyester Nonwoven Geotextile:

200g/m2, 250g/m2, 300g/m2, 350g/m2, 400g/m2, 450g/m2, 500g/m2, 600g/m2, 800g/m2

1.woven geotextile(reinforced geotextile)

2.Materials:PP

3.Tensile strength:15~100kn/m

4.Unit weight:100~400g/m2

5.Width:1 ~ 6m

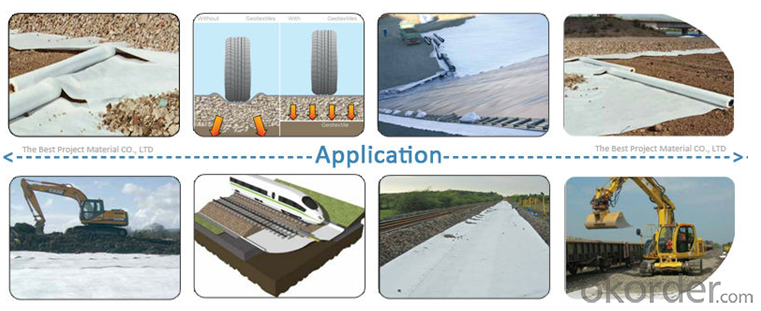

Applications of Polyester Nonwoven Geotextile:

Used in many civil engineering and building applications. Designed to offer filtration, separation, and ersion control functions.

Application industry

Some commen uses of the material includes the following:

1.Road stabilization applications

2.Roofs

3.Civil applications

4.Railway work

5.Landfill lining

6.Trenches

7.Dams

8.Fitration under rip rap and rocks

9.Environmental applications

IMages of Polyester Nonwoven Geotextile:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Geotextile CBR tear strength rate is how much

- Geotextile CBR bursting strength is generally in accordance with the national standard GB / T-2017 "geosynthetics static top breaking test (CBR method)" according to the national standard GB / T-2017 standard requirements of geotextile CBR strong pre-tension 20N. According to the national standard GB / T-2017 standard requirements of geotextile CBR strong rate of (50 ± 5) mm / min.

- Q: What are the key factors affecting the hydraulic conductivity of geotextiles?

- The key factors affecting the hydraulic conductivity of geotextiles include the size and shape of the geotextile fibers, the porosity of the material, the thickness of the geotextile, and the applied pressure or load. Other factors that can influence the hydraulic conductivity include the type of soil or aggregate being filtered, the presence of any clogging materials, and the overall condition and integrity of the geotextile.

- Q: Geomembrane bag bag is geomembrane or geotextile

- Neither is the geotextile bag made of woven cloth

- Q: Can geotextiles be used in erosion control in stormwater detention ponds?

- Yes, geotextiles can be used in erosion control in stormwater detention ponds. Geotextiles are commonly used to stabilize and reinforce soil, prevent erosion, and filter water in various construction and environmental applications, including stormwater management. By placing geotextiles on the slopes and bottoms of stormwater detention ponds, they can help prevent soil erosion caused by the flow of stormwater, reduce sedimentation, and improve the overall effectiveness of the pond in controlling and managing stormwater runoff.

- Q: What are the key considerations for geotextile installation in areas prone to landslides?

- The key considerations for geotextile installation in areas prone to landslides include: 1. Site evaluation: Conduct a thorough assessment of the site to understand the slope stability, soil conditions, and potential triggers for landslides. This will help determine the appropriate type and strength of geotextile needed. 2. Design and engineering: Engage geotechnical engineers to design a tailored solution based on the specific needs of the site. They will consider factors such as slope gradient, soil type, and expected loads to determine the appropriate geotextile specifications. 3. Drainage management: Proper drainage is critical to prevent water accumulation, which can increase the risk of landslides. Geotextiles can be used to enhance drainage by allowing water to pass through while retaining soil particles. 4. Anchoring and securing: Geotextiles should be securely anchored to the slope to ensure stability. This may involve using appropriate anchor systems or integrating the geotextile into the existing slope or retaining structure. 5. Monitoring and maintenance: Regular monitoring is essential to identify any signs of distress or movement in the slope. Timely maintenance and repair of the geotextile system can help prevent potential failures and ensure its long-term effectiveness in landslide-prone areas.

- Q: What is the latest price of geotextile?

- Per ton of national standard short geotextile 7000-8000 yuan, filament geotextile per ton - yuan.

- Q: What are the different guidelines for geotextile installation in erosion control projects?

- The guidelines for geotextile installation in erosion control projects may vary depending on the specific project and site conditions. However, some common guidelines include conducting a thorough site assessment, properly preparing the subgrade, ensuring proper overlap and seam strength of geotextile materials, adequately anchoring the geotextile to prevent movement, and regularly inspecting and maintaining the geotextile for any damages or clogging. Additionally, following manufacturer recommendations and consulting with experienced professionals can also provide valuable insights for successful geotextile installation in erosion control projects.

- Q: Are geotextiles effective in preventing soil erosion?

- Yes, geotextiles are effective in preventing soil erosion. They act as a barrier that prevents soil particles from being carried away by water or wind, while still allowing water to pass through. This helps to stabilize the soil and reduce erosion, making geotextiles a valuable tool in erosion control measures.

- Q: Are geotextiles resistant to fungal growth?

- Yes, geotextiles are generally resistant to fungal growth due to their synthetic nature and the materials they are made from.

Send your message to us

Non-Woven Polypropylene Geotextile Fabric Reinforcement Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords