Us Fabrics Geotextile Non Woven Geotextile for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

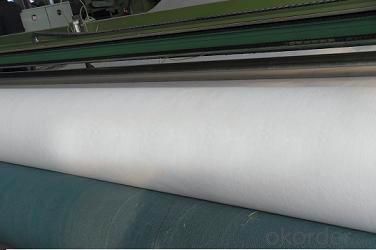

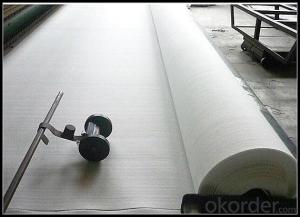

Structure of Non Woven Geotextile Description:

Nonwoven geotextiles are multi-purpose fabrics that are felt-like in appearance.Nonwoven Geotextiles are available in varying strengths and thicknesses to ensure appropriate material selection for your project. Custom roll sizes are also available.

Main Features of the Non Woven Geotextile:

1.Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different

granule pathway from the groundsill or other buildings.

2.Reinforcement

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earthbody stability.

3.Protection

It prevents the bank from being washed out, protects the bank and the

bottom, prevents the water and soil from being washed away

Non Woven Geotextile Images

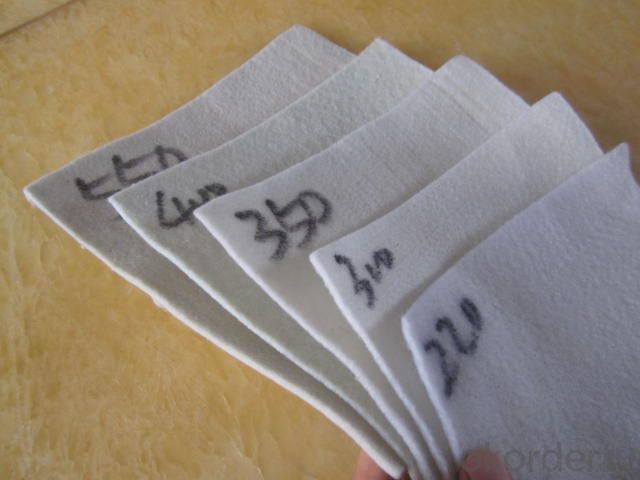

Non Woven Geotextile Specification:

Material | PET(polyester) OR Polypropylene |

Weight | 100g/m2-800g/m2 |

Width | 1-6m |

Length | 100m(or as your demand) |

Packing | Standard Export Packing. Or Packed as customers' requests. |

Payment terms | TT/LC |

Delivery time | 15-30days |

Items | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Note |

Quality error in unit area% | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness .mm.≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Error of width.% | -0.5 | |||||||||||

Breaking strength,KN/m≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | CD MD |

Elongation at break≤(%) | 25-100 | |||||||||||

CBR bursting strength KN≥ CBR | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

Effective aperture090(095)mm | 0.07-0.2 | |||||||||||

Vertical permeability coefficient cm/s | Kx(10-4-10-3) | K=1.0-9.9 | ||||||||||

Tearing strengthKN≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: What are the cost considerations for geotextile applications?

- The cost considerations for geotextile applications include the initial cost of the geotextile material, installation costs, maintenance and replacement costs, and the potential long-term cost savings. Additionally, the type and quality of the geotextile, site conditions, and project specifications can also impact the overall cost of geotextile applications.

- Q: Seepage geotextile and impervious geomembrane

- It is generally believed that the individual geotextile does not have the anti-seepage effect, the main assessment index is the permeability coefficient, the general geotextile coefficient is higher than the ordinary soil, about 0.01-0.001 look, but the geotextile and rubber, Asphalt, plastic combination will form a water-impermeable composite, anti-seepage effect increased by 10 times, and asphalt, rubber combined into a waterproofing membrane such as sbs, etc., and plastic is generally polyethylene, polyvinyl chloride, eva (standard name is Geomembrane) is a combination of impermeable geomembrane or composite geomembrane, because the composite white geotextile outside the protective effect, so the project is also called impermeable geotextile. Therefore, the two are essentially not much difference, but the argument is different. Waterproof board is also called geomembrane, customary to> 0.8mm thick geomembrane called waterproof board, & lt; 0.8mm called geomembrane, it is based on high molecular polymer as raw material made of impermeable material , Divided into homogeneous waterproof board and composite waterproof board

- Q: How to apply geotextile soil

- Directly laying Huazhi geotextile material manufacturers

- Q: Can geotextiles be used in mining applications?

- Yes, geotextiles can be used in mining applications. They are commonly used in mining for various purposes such as erosion control, soil stabilization, and filtration. Geotextiles can help to prevent soil erosion on slopes, reinforce weak soil structures, and separate different materials in mining operations. Additionally, they can aid in water management by acting as a barrier or filter to control sedimentation and drainage.

- Q: 200g / m2 geotextile how to enter the inspection test

- 200g / m2 geotextile how to enter the inspection test

- Q: Are geotextiles poisonous?

- Geotextile is not toxic, the production of geotextile raw materials are polyester (PET) or polypropylene (PP). Polyester and polypropylene have become daily necessities. Many of the mineral water bottles are also produced by PET and PP raw materials.

- Q: Are geotextiles resistant to hydrocarbons?

- Yes, geotextiles are generally resistant to hydrocarbons.

- Q: What are the design considerations for geotextile-reinforced slopes?

- Some of the key design considerations for geotextile-reinforced slopes include the selection of appropriate geotextile material, the determination of proper reinforcement spacing and orientation, the assessment of slope stability and soil characteristics, and the consideration of environmental factors such as water drainage and vegetation. Additionally, the design should take into account the expected loads and stresses on the slope, as well as potential erosion and long-term durability of the geotextiles.

- Q: How do geotextiles aid in the protection of geomembranes?

- Geotextiles aid in the protection of geomembranes by acting as a barrier between the geomembrane and the surrounding soil or aggregate. They provide cushioning and support, preventing direct contact and potential damage to the geomembrane from sharp objects or uneven surfaces. Additionally, geotextiles can assist in preventing soil erosion and the migration of fine particles, enhancing the overall stability and longevity of the geomembrane installation.

- Q: Welding geotextile how to apply the mattress on or below

- The company specializes in the production of geotextile, geomembrane and other geotextile materials to undertake welding works!

Send your message to us

Us Fabrics Geotextile Non Woven Geotextile for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords