Non Asbestos Fireproof Calcium Silicate Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

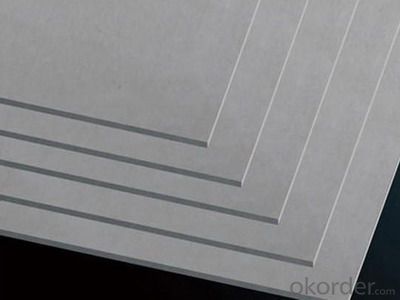

It contains inorganic raw materials such as cement, silica powder and reinforced cellulose fiber as the main materials. All ourboards are autoclaved to become stable products. It does not contain any asbestos fiber; however, it has strong bending strength like those with asbestos.

It can be applied not only in the interior use but also in the outdoor walls. It has low water absorption rate and high impact resistant ability. These advantages make it suitable for any purposes of applications.

Product Applications:

1) Old and new building curtain walls, exterior walls and other outdoor systems

2) European and American styles of architecture and high-end villa roof

3) Indoor hall, office, building facade and podium

4) Kitchen, bathroom, bathrooms, changing rooms and other damp places

5) Subway stations, tunnels and underground works

6) Interior wall decoration system

7) High quality requirements of the ceiling

8) Environmental requirements, particularly Germany occasions

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

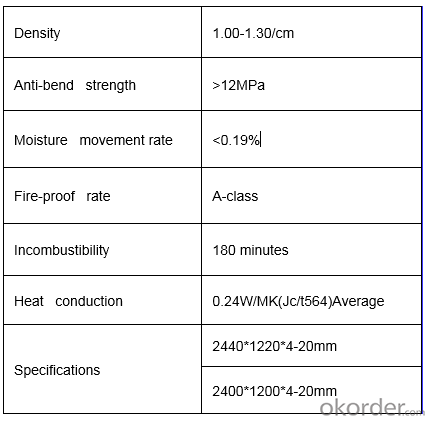

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q: Is the calcium silicate board and the Etter plate the same material?

- Calcium silicate board is the domestic follow-up imitation of the product. Although the raw materials are basically the same, but the proportion of raw materials and other ingredients added, as well as the production process is different due to the differences in these factors, product density, water resistance, fire performance are very different.

- Q: Calcium silicate board and magnesium silicate board which is better

- In recent years, with the improvement of production technology, the use of calcium silicate board is also more and more common in Guangdong, in addition to the external brand of Etterit, there are Oulang, Jinfu, Chun Figure, Yin Xing and other own Brand.

- Q: Home improvement ceiling with a special board, scraping the cover is a good place is rural?

- Then come back to ask questions. Usually the national standard is low, we Ete's corporate standards to be higher than the national standard. Etter board thickness has a lot of 6-12mm range. But for the ceiling is also due to project vary. Some room ceiling related to fire protection requirements, then we usually choose low-density series 8mm or 10mm; some just a simple office ceiling, then the medium density of 6mm can be Edite board is not calcium silicate board. The name of the Aite plate is a fiber-reinforced silicate plate. The board is imported from the plant fiber, not the ordinary calcium silicate board.

- Q: Where to produce 3 m long reinforced fiber calcium silicate board

- Fiber reinforced calcium silicate board is a new building decoration material from 2011 to 2012. The fiber reinforced calcium silicate product has the advantages of light high strength, fireproof insulation, durable, low shrinkage rate, good processing performance and easy surface decoration. , Is widely used in building interior and exterior decoration, ventilation pipes, sound-absorbing panels, fire wall panels and a variety of special-purpose industrial facilities

- Q: Integrated ceiling and calcium silicate board which is good

- Waterproof fire performance than the wood is much better ... ... and easy to clean up not afraid of soot But it is bad to return to the South do not absorb the water ... ... but also anti-tide ... ... that is likely to drip down

- Q: What is the difference between gypsum board and silicon calcium board?

- Gypsum board is a building gypsum (that is, CaSO4) as the main raw material, mixed with appropriate amount of additives (adjust the rate of condensation) and fiber to do plate core, with a special plate for the face, the processing of the plate. Strength is not high, not wet

- Q: FC and calcium silicate board which is good

- Fiber cement board (fiber cement board abbreviation for the FC board), also known as fiber reinforced cement board. Calcium silicate board and fiber cement board, although all belong to the fiber reinforced inorganic non-metallic plate, with low density, medium density and high density of the points, but because calcium carbonate board raw materials in the calcium material is lime and add the appropriate amount Reinforced materials by pulping, molding, high temperature autoclave and other processes made, suitable for low density and medium density light board. Fibrous cement board of calcium material is cement, and there are autoclaved and non-autoclaved products, suitable for medium density and high density board.

- Q: How do I distinguish between calcium silicate boards and asbestos? I heard some people use cement board instead of calcium silicate board, containing asbestos ingredients!

- Asbestos fiber cement products for interior and exterior decorations and indoor ceilings, the fine asbestos fibers contained in the light, if they are inhaled, may cause refractory asbestos lung disease, which can cause various cancers and bring great (Such as Germany, France, Sweden, Singapore, etc.) has banned the production and use of all asbestos products.China has also some companies began to produce non-asbestos cement sheet.Therefore, in the decoration of the house, in the Conditions permitting, the choice of non-asbestos cement products is better.

- Q: Does the calcium silicate factory pollute? What is the harm to people? Please know the big god reply! Thanks

- Environmental hazards are dangerous to people's health

- Q: Silicon calcium board and gypsum board which is good There are calcium silicate board and security board. What are the differences between these boards?

- The price is about three times the cost of gypsum board, it is recommended to use gypsum board decoration. Gypsum board line brand dragon card, Lafarge, can be resistant, cheap second and third line brands such as Taishan, according to your standard decoration bar

Send your message to us

Non Asbestos Fireproof Calcium Silicate Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords