Fireproof Calcium Silicate Board Non-asbestos

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

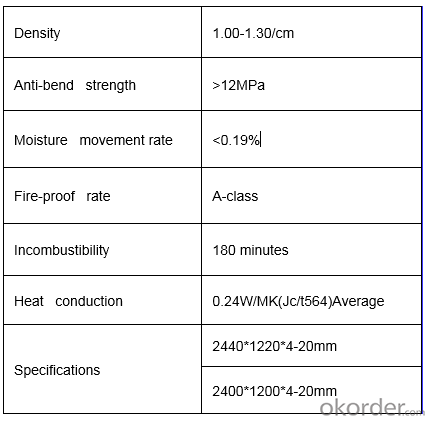

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q: Calcium silicate board production line

- Flow slurry method is equipped with a stirrer and separator in the headbox. When the slurry reaches a certain level in the headbox, it flows naturally through the horizontal cloth pulp plate and the inclined flow slurry plate to the blanket to form the initial material layer, The initial material layer through a number of vacuum box forced dehydration, winding to the forming tube I, to achieve the required thickness from the molding tube after pulling the wet blank, the next process into a variety of products.

- Q: Just 6mm of calcium silicate board to do smallpox will not crack

- Calcium silicate board has excellent water resistance, in the bathroom, bathroom and other places of high humidity, can still maintain the performance of stability, will not swell or deformation. Calcium silicate board high strength, 6mm thick plate strength greatly greater than 9.5mm thick ordinary gypsum board.

- Q: What is calcium silicate board?

- As a new type of building plate can be used for industrial and civil construction of the partition board and ceiling panels, the surface after the water treatment can also be used as building exterior wall and composite insulation system, especially high-rise building large format wall The Because this plate has a good fire resistance, especially for the building steel structure, bearing the cover of the fire (Table 1). Although the calcium silicate board in a variety of different applications have a corresponding alternative products, but in the application of the effect and cost there is a big difference, cost-effective. As compared with the paper gypsum board, the silicon count is slightly better than the paper gypsum board in the construction, the strength, moisture, fire, life and so on are significantly better than the paper gypsum board.

- Q: Calcium silicate board commonly known as what

- Decorated with calcium silicate board, calcium silicate board by the United States OCFG company invented, is a comprehensive performance known to the world of new building plate, the 20th century, 70 years in the developed countries to promote the use and development. Europe and the United States, Japan, Australia and Taiwan is the most common use of calcium silicate board countries and regions, China in the early 80s successfully developed, the mid-80s into the development stage, the late 90s to get a large area to promote the application. Thickness of 4-20mm, length and width to 1220 * 2440mm mainly. At the same time to have a large size of calcium silicate board processed into a decorative calcium silicate ceiling, its anti-sagging varieties and other advantages, is widely used in the ceiling.

- Q: What is the new environment of environmental protection wall insulation materials

- 1. Building materials used in the source of raw materials, such as: fly ash, coal gangue, quartz sand, tailings, rice bran, wheat straw, cotton stalks, sawdust, construction waste. 2. Raw materials can not contain harmful substances prescribed by the State 3. Production of low energy consumption, such as: the previous clay brick energy consumption, take up a lot of land resources. Now the energy consumption of unburned brick is much lower. 4. Green building materials quality light, transport aspects 5. Recyclable

- Q: What are the advantages of calcium silicate board?

- The strength of more than 10MPA than most of the plate strength are high; density between 0.6-1.4 (in addition to some of the higher strength of the pressure forming plate), as insulation materials more energy; the use of wood fiber and inorganic high temperature, In the high humidity state does not decompose the decomposition of non-toxic gases (decomposition only release water vapor); due to calcium carbonate plate autoclaved products and air in the water vapor, oxygen, carbon dioxide do not react, so the service life is equivalent to building life The

- Q: Hydrate calcium silicate gel under what circumstances

- Hydrate calcium silicate gel under what circumstances

- Q: What is the difference between silicon calcium board and high crystal plate?

- Silicon calcium board is the traditional use of gypsum, silicate cement and potential reactive powder to do the ceiling plate, easy to deformation discoloration damp, the north can be used with a place, the southern wet spots may not be suitable.

- Q: What is the difference between silicon calcium and cement fiberboard?

- Fiber cement pressure plate and calcium silicate board are common architectural decoration materials on the market, its appearance and composition are many similar or even the same place, many people can not distinguish, and some businesses even calcium carbonate board posing as fiber cement pressure plate sales , Has reached the purpose of profit.

- Q: Calcium silicate board the greater the density of the better performance?

- Now the majority of the market are coated with the physical pressure, and some autoclave autoclaved through the cement pressure plate.

Send your message to us

Fireproof Calcium Silicate Board Non-asbestos

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords