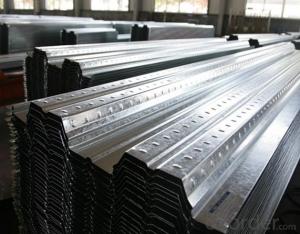

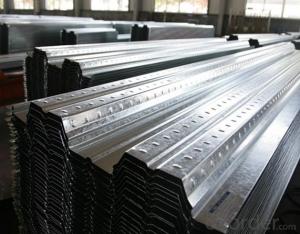

No-edge Raised Floor(Steel Panel) good quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 g/m²

- Supply Capability:

- 500000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

No-edge Raised Floor(Steel Panel)

Model: HGD600

Dimension: 600×600×35(mm)

This product without black edge trim, is made of quality steel plate, which is stretched forming, point welded and plastic sprayed with bubble cement filler filled in its inner cavity. The fire-resistant decoration plates that can endure high temperature adhere to its surface with conductive chips embedded around it. The pedestals and cross beams are wholly plated with zinc and the height of pedestals is adjustable and can be self-locked.

TYPE | Concentrated Load | Impact Load | Ultimated Load | Uniform Load | Rolling Load | |||

LB | N | KG | N | N | N/㎡ | 10passes | 10000passes | |

HGD600-Q | ≥800 | 3550 | 363 | 670 | ≥9400 | ≥14680 | 3560 | 2670 |

HGD600-B | ≥1000 | 4450 | 453 | 670 | ≥11970 | ≥16900 | 4450 | 3560 |

HGD600-Z | ≥1250 | 5550 | 567 | 670 | ≥14360 | ≥22240 | 5560 | 4450 |

HGD600-CZ | ≥1500 | 6660 | 680 | 780 | ≥17950 | ≥26690 | ≥6670 | 5560 |

Features

Designed specially for computer room & clean room

Excellent rolling load & ultimate load performance

Light weight cementitious fill makes panels solid and quiet

Completely non-combustible

Black electrodeposition cathodic epoxy paint finish for life time protection

Class A flame spread and smoke development rating

Wide range of finishes available

Applicable Fields

Computer rooms, programmed control equipment rooms, electrical-controlled classrooms, places that have requirements of dust-proof and anti-static, and fields with aerial requirements.

- Q: What is the anti-static floor edge material

- The edge of the edge of the plant with the material is not sturdy shield box Yong Valley fall Yan Kai Kai, there are all steel, there are alloys, PVC, etc., as long as the conductive, are in use, the price is low to the provincial cost of the principle, Good quality to use good materials, there are no side of the floor.

- Q: Why the same is the polyester fiber clothes some static serious some will not

- The disadvantage of polyester fiber is easy to adsorb dust, resulting in static electricity. Wearing polyester fabric fabric is easy to contaminate the dust, not only cause unsightly, the most annoying is the static electricity, not only feel tingling, and if the pants will be because of the electrostatic relationship close to the skin, completely lost Clothing pants type, very unsightly. In order to avoid the defects of polyester fiber, some clothing brands in the fabric of the fabric by adding spandex, cotton and other materials can greatly reduce the generation of static electricity, which appeared with the polyester fiber clothes some static serious some will not be the case The

- Q: Is the insulation floor and the anti - static floor the same thing?

- Anti-static floor is insulated floor, insulated floor is not necessarily anti-static. If you have more questions, you can click on ID consultation.

- Q: Is the computer classroom anti - static floor professional qualification?

- As long as the regular manufacturers to buy, with a good anti-static effect, is not needed

- Q: Anti-static floor also used shop insulation rubber it?

- According to the rules, high pressure changes need to shop, the general room is not needed

- Q: Room cabinet from the UPS distribution cabinet to take power, anti-static floor below the need to put a socket? Please recommend several commonly used

- Direct PDU on the line.

- Q: What is the overhead floor

- There is room below the floor. Such as the floor of the stage, keel floor.

- Q: How is the floor of the anti-static floor?

- Anti-static floor (including ceramic anti-static floor) in the laying, be sure to carry out anti-static grounding and then protect the resistance box, so as to play the effect of anti-static effect. In the anti-static grounding process in the ground connection is mainly used for anti-static pad grounding between the socket can be effective in the production work of the human body or pad to the electrostatic discharge to the earth. Antistatic grounding wire is mainly electrostatic grounding wire grounding wire components, including polyurethane straight or slingshot line, in the two ends of the head with suction cups, claws nails, ring terminals, button deduction, alligator clip If you want to achieve a simple ground pad, One end with 10mm universal button to connect table mats or mats, the other end of the connection to the public grounding point, the 10mm buckle precision injection molding, with green and yellow wiring, beautiful and durable. For the Taiwan ground universal grounding wire, often equipped with claw nail-type metal buckle, easy to install directly on the table mat; the other end of the ground wire with a banana plug and alligator clip, easy to insert the grounding socket and directly clamp the ground wire, through the ground The line will work in the static electricity generated by rapid discharge.

- Q: Construction of weak and fire control room must do anti-static floor? Has there been any impact on future acceptance?

- It is not necessary to recommend doing static flooring

- Q: How to properly regulate the installation of pvc plastic anti-static floor

- First, the mobile installation: between the floor and the floor with the manufacturers supporting the special connection with a bonding tape, floor and floor surface is not bonded, you can freely roll up or remove the PVC floor, easy to move. Second, the fixed installation: 1. Semi-fixed: special double-sided tape, between the floor and the floor with the manufacturers supporting the special double-sided adhesive tape with one, while the floor and the ground is also connected together, can effectively prevent The floor due to strenuous movement and the occurrence of movement, opening, but also facilitate the future because of the need to do the entire site to move. 2. Local bonding: on the ground to the edge of the floor as the reference inward brush 20cm adhesive. 3. Full Adhesive Adhesive: All the brushes are to be laid on the ground. [Grass-roots requirements]: construction ground floor must be clean, durable clean, high flatness, and no cracks. The concrete surface moisture content can not exceed 2.5%. Gypsum floor moisture content shall not exceed 0.5%. Before the floor laying. Floor after dust, you can lay PVC plastic sports flooring. Such as the original rough surface can also be built about 2mm self-leveling. If it is non-absorbent ground, such as mineral grassroots, stone, tiles, etc., can be directly pavement. 【Note】: If the basement and other wet ground, the floor must be waterproof layer to isolate water vapor.

Send your message to us

No-edge Raised Floor(Steel Panel) good quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 g/m²

- Supply Capability:

- 500000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords