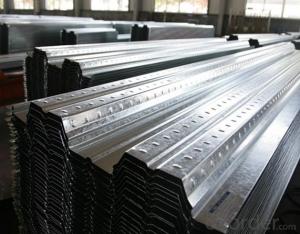

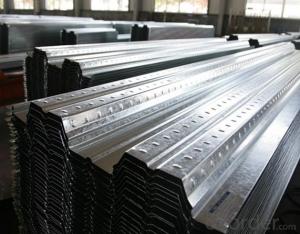

Floor Decking Steel Panel with good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Sichuan China (Mainland) | Brand Name: | Baoye | Model Number: | BYF2 |

| Material: | Galvanized Sheet |

Packaging & Delivery

| Packaging Detail: | standard export package |

| Delivery Detail: | 20 days after downpayment |

Specifications

Floor decking steel panel is formed by floor deck forming machine, use galvanized steel at thickness 0.7-1.2mm

Floor decking steel panel is formed by floor deck forming machine, use galvanized steel at thickness 0.7-1.2mm, put the panel on the supporting H-beam, fill cement on it. It is mainly used as the floor of multiple floor buildings, it can lighten the weight and save with same loading capacity.

1.Strong friction and shear performance

The closed-type floor decking sheet uses special closed rib design and its vertical shear performance is good . Under the limitation allowance of the truss floor deck’s design loads,steel deck and concrete don’t slip off each other.

2.Perfect fire-resistant performance

Rib is completely encased in concrete,similar t reinforcing steel bars in the concrete slab which is site pouring.The closed-type composite slab can completely substitute the sagging moment reinforcing steel bars for pulling in the floor and can be up to 1.5 hours of fire-retardant coating .

3.Excellent floor decking sheet section

The closed-type composite slab has greater effective height,during the stage of use,it can provide greater resistance to sagging moment.

4.Slot-tye suspension system at the end of sheet

It is for the installation of ceiling,hung ceiling,water and electricity pipe,etc,without drilling,welding,during the stage of using,it can be moved,removed and reinstalled as needed.

5.East and fast to construct

It does not require any plug at the end ,and there is no leakage of plasma phenomena,it can shorten the construction period.

6.Flat appearance f the end of sheet

The end of slab is flat and beautiful for the building which don’t want ceiling.

7.Effectively reduce the height of the sheet

According to the requirement of fire safety and anti-tremor,the total thickness of the closed-type corrugated floor decking sheet is only 110-130mm,30-40mm less than the open-type,so it reduces the weight and cost and add the net height.

8.Low cost

The closed-type pressure plate can substitute the sagging moment reinforcing steel bars at the end of sheet,and there is no need to paint any fire-retardant coating,it reduces the steel amount and then lowers the cost.

- Q: EVA is not a gospel warrior, rubbing experience can leave. Saying that my road has a curvature, how to make EVA board stereotypes. The The With the hair dryer are hot and did not respond. The The Is it my fault? And if the use of epoxy resin or atomic ash how to use Thank you to answer, rub the experience of the chat there are simply do not know the cloud of the shotgun wait. The The I want a ...

- Do props 13551 44205 here is really very tangled

- Q: What are the characteristics of KRD blue epoxy sheet?

- "KRD blue epoxy plate" in 1938 by the German company in Switzerland patent application in Switzerland, 1946 secretly put into operation in the high-end military plate, in 2008 Germany Kerui De company in the original epoxy board formula based on improved by adding KRD blue Water resistant weather factor, to produce high-end "KRD blue epoxy plate", put the German market, mainly used in luxury cruise ships and high-end cars and high-end interior furniture production. October 2009 European style (Hong Kong) bathroom International Development Co., Ltd. formally introduced "KRD blue epoxy plate" production line into the civilian bathroom furniture production. ????"KRD blue epoxy sheet" has a strong chemical resistance and water resistance. In the curing system of ether, benzene ring and fatty hydroxyl is not susceptible to acid and alkali erosion. Can be used for two years in seawater, petroleum, kerosene, 10% H2SO4, 10% HCl, 10% HAc, 10% NH3, 10% H3PO4 and 30% Na2CO3, and half a year at 50% H2SO4 and 10% HNO3; % NaOH (100 ° C) for a month or soaked in fresh water for 50 years, the performance remains the same. ????"KRD blue epoxy plate" molecular chain structure contains two or more epoxy groups of polymer compounds, process performance is good, strong nail holding force, product size and stability, no radiation, zero formaldehyde, is the current The forefront of the international environmental health, strong weather resistance of high-end furniture preferred plate. "KRD blue epoxy plate" Appearance features: A high density light B The appearance of the plate is light blue C strong flexibility

- Q: The normal size of the solid wood board

- Long 243.84 cm wide 121.92 cm from the British standard 8 feet long 4 feet wide.

- Q: How to identify the millennium boat plate

- It is not what you do, belong to the cultural relics, and need archaeologists identification.

- Q: Stainless steel industry in the non-standard plate, non-standard What does this mean?

- In the national standard, the product specifications, the content range of the elements and many other indicators are made in detail, which also includes the approval of the implementation of the country, the standard standards and industry standards, but without the factory standard, that is, Factory-defined standards, If the relevant provisions do not meet these standards as a substandard product, But sometimes these standards within the provisions of the product can not meet the needs of the use of units, such as a user can only use thick 9mm board, but the product standard series is not, only with manufacturers agreed to special processing, this product is called non-standard , But also the quality of processing failed, but some manufacturing can also be used, or downgrade also known as these non-standard products, GB3280-1984 is a stainless steel plate of the national standard

- Q: What are the characteristics of wood?

- Light weight, high strength than high, good elasticity, impact resistance, easy processing

- Q: Always said that the plate is very complex, think about learning a little professional knowledge

- Can be distinguished by the following steps and methods: First is "see", but also to see the focus. Good plate surface smooth and smooth, the edge of the board is very clear. As well as the packaging on the plate is clear, the above name, address, grade, specifications and other information are complete, not clear, incomplete information or more attention to the plate, and may be added to the color of the plate. Two smell, because the legendary formaldehyde is released from the plate, will directly affect people's health. Good plate not only good choice of materials, but also for the adhesive glue is environmentally friendly, even if the number of more stacked together, it will not emit a very pungent taste. If the choice of a plate placed in the home there is a very obvious pungent chemical smell, it should be noted. ?Three saws, before the purchase can be a small sample to the business, and then cut it to see its inner core, a good plate section level is very clear, because it is a layer of paste a very tight, very good convergence, and those miscellaneous Wood stitching the poor quality of the plate core is not dense, must not buy. Four test, through the relevant identification agencies, with professional tools and related technical means to identify the plate to determine the quality of good or bad, this method is more professional and accurate. Plate material is also an important factor is the moisture content, the general moisture content of the plate should be less than 16%, if too high that is not good, may be a while will be mildew or deformation.

- Q: What are the characteristics of spruce plate?

- Strong pine wood] to answer your questions about wood! ?? Spruce, also known as European white pine, its fine texture straight, material stability, not easy to deformation cracking, strong resistance, while easy to planing, planing the surface after the smooth, bright, can absorb paint and colorants, and Easy to glue. It itself has a soft color, fine texture and natural texture is very natural into the furniture design, showing a simple original beauty. Spruce has a variety of advantages and uses a wide range, has been hailed as "the Nordic green diamond." ????? Main use: furniture components, housing ceiling, decorative keel, floor, shutters, cabinets, wall panels, musical instruments, organ tubes, boxes, wooden barrels, joinery, cutting wood, sleepers, building structural materials, Bridges and other timber.

- Q: Wardrobe to choose how thick the plate

- Wardboard cabinet plate is probably distributed; back plate 9mm, layer board 12mm, side panels are divided into 12mm and 24mm, bookcases and usually with 24mm, desk with 32mm! As you ask the sliding plate, usually the wave board, the thickness is 9mm, but also useful flat panel, the thickness is 12mm! That the door of the sliding door, that is, it has a titanium alloy size! Out of range you are not installed!

- Q: Want to do the whole wardrobe in the bedroom, because of the reasons for the budget so I would like to ask what kind of sheet to do the overall wardrobe more affordable, more argument, I recommend solid wood composite board, and some remember, we talk about , Ask a question, the bathroom cabinet with PVC or solid wood particles can be it?

- Now there are more on the market in the MDF, you can buy their own plate and then find workers on-site cabinet. The The Bathroom cabinet board to use a good moisture-proof plate, you can use melamine board

Send your message to us

Floor Decking Steel Panel with good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords