Popular Raised Floor with Ceramic finish(Steel Panel)

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

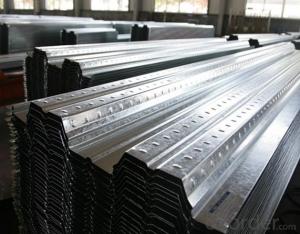

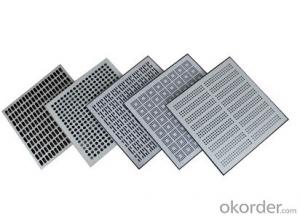

Raised Floor with Ceramic finish(Steel Panel)

Model: HBD600

Dimension: 600×600×35(mm)

Specifications:

1) Cover materials: 10mm ceramic tile

2) Color: as required

3) Tolerance:

a) Width and length: -0.4mm - 0.0mm

b) Panel thickness: +0.30mm

c) Level:<0.6mm4) Sizes: 600 x 600 x 40mm

Features:

a) Surface is treated with static painting with good corrosion resistance

b) High precision for dimensions, good interchangeability

c) All steel structure with high strength and strong anti-impact capability

d) Antistatic, fireproof, waterproof and dustproof

e) Floor can be cut randomly, easy installation due to accessories

f) Space under floors can be used for air conditioning ventilation

Installed Example

- Q: Anti-static activities of the floor by which the map set

- I do not know the practice is the standard production standards or construction requirements?

- Q: Ceramic anti-static flooring and PVC anti-static floor which is good wave tripod anti-static floor to tell you

- PVC anti-static floor is the interface between the PVC particles to form a conductive network, the environment has a request (clean, blessing brother Yi Xi anti-Austin Ding Ding preserving fireworks), ceramics need to say the resistance is stable, durable, resistant to pollution Aging, carrying capacity strong! On the popular, PVC resin is good, on the practical, or ceramic good! Individuals quite ceramic.

- Q: The room and shop the floor and the use of static wiring on the bridge wiring, scientific and reasonable?

- Yes ah this is nothing is unreasonable is a practical request Many telecommunications room are used, Hengtong Xin Hong anti-static floor...

- Q: PVC anti-static floor of the anti-static index is how much

- Anti - static plastic floor of the technical parameters

- Q: Cordless Electrostatic Ring No Ground Wire The man's own static electricity comes there? Question added: what do you mean by neutral? The Do not understand only to learn shallow! The The More

- The principle of cordless static ring floating touch of the first bark Ying Du is also through the 1M ohm resistor discharge to avoid instantaneous large current damage to the components and the human body! Static electricity is through the air to eliminate (neutral way to eliminate), but still a rope electrostatic ring effect is better!

- Q: Room anti-static floor, how much the price of a flat

- According to the budget and the use of choice of price space is very large, from more than 100 to more than 1000 have, Hengtong Xin Hong anti-static floor

- Q: How to clean the room floor

- PVC permanent anti-static floor maintenance and maintenance 1, is strictly prohibited with the nail shoes walking on the floor. 2, is strictly prohibited hard objects, hardware on the floor characterization, in particular, equipment transport routes and the installation of equipment around the top of the blessing Lennon locusts Wei Chuan even to cushion plywood, and floor scratches and oil pollution. 3, the floor construction is completed, handling machinery and equipment is strictly prohibited machinery and equipment in the floor drag Sassafras. 4, is strictly prohibited with a solvent spray paint the surface of the floor. 5, the production area should wear soft shoes or feet into the work area, prevent dust into the workplace. 6, is strictly prohibited permeability of the ink, mechanical oil pollution floor surface. 7, to prevent the weight of the trailer on the floor surface pressure, the production of tires selected tires to avoid easy to decolorize the vinyl tires, the proposed use of nylon tires. 8, the surface of the floor there is pollution, with gasoline, wash clean, decontamination powder cleaning the floor surface, and then the surface of anti-static wax light treatment. 9, the floor is generally cleaned once a year, and then on the anti-static floor wax lighting maintenance treatment.

- Q: Ceramic surface anti-static floor What are the characteristics

- (1) anti-static: the activities of the floor system resistance is stable and durable. System resistance 10 of the order of 10 to 10 of the 10 power Ω. (2) resistance to pollution: the porcelain brick surface by improving the product raw material formula to reduce the pores and reduce the small pores and the surface of the brick coated with a layer of special coating, so that the juice is difficult to penetrate the internal, thus solving the " The old problem. (3) no radiation: the ceramic tile test by the National Building Materials Testing Center, without radioactive elements, safe and reliable, to ensure that the protection of the pilgrims and dumplings bogey bogey Kong Kung Long health, natural stone is the ideal alternative to the material. (4) anti-aging: good quality, hardness of Mohs 7 degrees, the service life of more than 60 years. (5) carrying capacity: uniform load greater than 1600 kg / square meter.

- Q: Construction of weak and fire control room must do anti-static floor? Has there been any impact on future acceptance?

- It is not necessary to recommend doing static flooring

- Q: Would like to ask epoxy anti-static self-leveling a few processes?

- This depends on how thick you are.

Send your message to us

Popular Raised Floor with Ceramic finish(Steel Panel)

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords