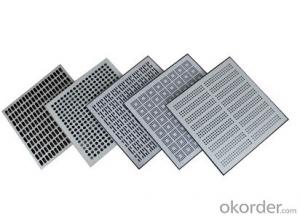

OA Bare Finished Raised Floor System(Bare Panel)

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OA Bare Finished Raised Floor System(Bare Panel)

Model: OA600-Q/B/Z/CZ

Dimension: 600×600×35/30(mm)

TYPE | Concentrated Load | Impact Load | Ultimated Load | Uniform Load | Rolling Load | |||

LB | N | KG | N | N | N/㎡ | 10passes | 10000passes | |

OA600-Q | ≥800 | 3550 | 363 | 670 | ≥9400 | ≥14680 | 3560 | 2670 |

OA600-B | ≥1000 | 4450 | 453 | 670 | ≥11970 | ≥16900 | 4450 | 3560 |

OA600-Z | ≥1250 | 5550 | 567 | 670 | ≥14360 | ≥22240 | 5560 | 4450 |

OA600-CZ | ≥1500 | 6660 | 680 | 780 | ≥17950 | ≥26690 | ≥6670 | 5560 |

Common specification/Panel material: Steel + Lightweight Cement

Pedestal

Low floor type High floor type

OA Steel Panel is made of quality steel plate, which is stretched forming welded and sprayed with bubble cement filled in its inner cavity. Its pedestal is plated with zinc and cast aluminum alloy, whose height is adjustable and can be self-locked. The steel panel can be shaped by either slicing or riveting. In order to meet the requirements of the multi-functional intelligent building, OA raised floor is equipped with double wiring chip boxes to avoid the unnecessary inconvenience. Installed by beamless angle bars, the panels are firm, stable and easy to handle.

Installed Example

Applicable fields:

OA Steel Panel is fit for intelligent office building, OA classroom or places need to be raised, dust-free or waterproof.

Characteristics:

All steel assembly structure with high strength and strong anti-impact ability.

High precision of dimensions and good interchange ability.

Surface is treated with static electricity painting, owning good performance for anti-corrosion and long life for use.

Fire-proof, water-proof and dust-proof.

Wiring chip port is molded forming to make it easier for assembling wires and outlet boxes.

Lower space can be used for air-conditioning ventilation.

With regard to bearing loads of excessive heavy equipment, the loading problem can be solved by adding pedestals under the floor.

Convenient work for both assembling and dismantling brings high re-use factor.

- Q: The difference between plastic floors

- The difference between plastic floors...

- Q: Anti-static activities of the floor by which the map set

- I do not know the practice is the standard production standards or construction requirements?

- Q: When driving the door when the old hands, met metal things also hands.

- This is the car's tranquil porridge Ganzhuang imitation wet storm splash does not matter, mainly dry winter weather, coupled with more clothes, friction between them from the static, you have not encountered in the summer electric hands...

- Q: Such as title

- With a wire, such as a flower thread and the like connected to the main chassis on the iron parts. The other end can nail a nail on the dry wall and connect the thread to the top. And the best way to wear shoes, the best solution is to transform the circuit

- Q: The anti-static floor of the engine room with any suitable baseboard

- Our room is wood ah

- Q: An electrostatic pad (static skin to be separated by a large amount of static electricity installed in the installation of an electrostatic buckle, such as an electrostatic pad length of 5M? The More

- Can not, to install 5 bar One per meter

- Q: Anti-static floor to do when the height from the ground whether there are relevant norms

- There is no specific norms, generally in the 15-25CM, according to the needs of customers, generally higher from the ground relative to its bearing capacity is also smaller.

- Q: What is the difference between a network floor and an anti-static floor surface material?

- 1, the network floor after the installation of the surface paste box carpet or magnetic PVC. 2, anti-static floor surface directly paste the long-sleeved short pot of the boudoir intoxicated flower HPL anti-static veneer, PVC anti-static veneer, permanent PVC anti-static veneer, and then install. View original post & gt; & gt;

- Q: In addition, the anti-static floor of the anchor room, the stent is the wooden keel removed after laying another classroom, the area is different. Is this okay? If not why can not it? More

- If you are using the original classroom floor and stent, it can, but if the second classroom area larger, then trouble, to increase the floor and stent, and increase the floor and the original floor will have color, It is ugly that if the second teacher is smaller than the first one, it can be. As long as the same factory with a floor, the general stent can be universal, if you change the other types of flooring, the original stent may not be used, to all replaced. If there is a problem, give me a message.

- Q: Why is the weak anti-static floor, which is the specification?

- 1) Since it is weak, certainly need to prevent current interference

Send your message to us

OA Bare Finished Raised Floor System(Bare Panel)

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches