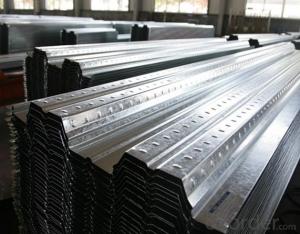

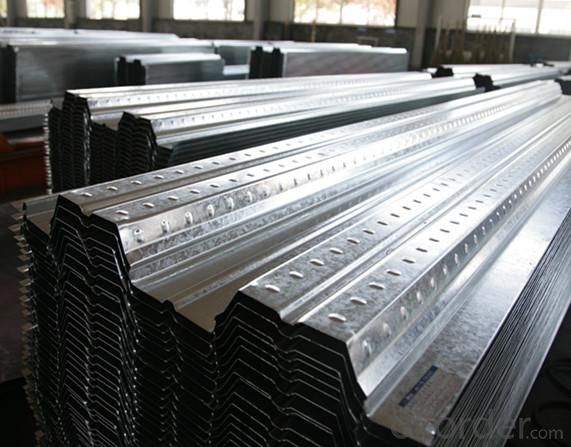

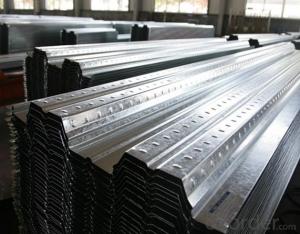

Floor Decking Steel Panel good quality with high standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Sichuan China (Mainland) | Brand Name: | Baoye | Model Number: | BYF2 |

| Material: | Galvanized Sheet |

Packaging & Delivery

| Packaging Detail: | standard export package |

| Delivery Detail: | 20 days after downpayment |

Specifications

Floor decking steel panel is formed by floor deck forming machine, use galvanized steel at thickness 0.7-1.2mm

Floor decking steel panel is formed by floor deck forming machine, use galvanized steel at thickness 0.7-1.2mm, put the panel on the supporting H-beam, fill cement on it. It is mainly used as the floor of multiple floor buildings, it can lighten the weight and save with same loading capacity.

1.Strong friction and shear performance

The closed-type floor decking sheet uses special closed rib design and its vertical shear performance is good . Under the limitation allowance of the truss floor deck’s design loads,steel deck and concrete don’t slip off each other.

2.Perfect fire-resistant performance

Rib is completely encased in concrete,similar t reinforcing steel bars in the concrete slab which is site pouring.The closed-type composite slab can completely substitute the sagging moment reinforcing steel bars for pulling in the floor and can be up to 1.5 hours of fire-retardant coating .

3.Excellent floor decking sheet section

The closed-type composite slab has greater effective height,during the stage of use,it can provide greater resistance to sagging moment.

4.Slot-tye suspension system at the end of sheet

It is for the installation of ceiling,hung ceiling,water and electricity pipe,etc,without drilling,welding,during the stage of using,it can be moved,removed and reinstalled as needed.

5.East and fast to construct

It does not require any plug at the end ,and there is no leakage of plasma phenomena,it can shorten the construction period.

6.Flat appearance f the end of sheet

The end of slab is flat and beautiful for the building which don’t want ceiling.

7.Effectively reduce the height of the sheet

According to the requirement of fire safety and anti-tremor,the total thickness of the closed-type corrugated floor decking sheet is only 110-130mm,30-40mm less than the open-type,so it reduces the weight and cost and add the net height.

8.Low cost

The closed-type pressure plate can substitute the sagging moment reinforcing steel bars at the end of sheet,and there is no need to paint any fire-retardant coating,it reduces the steel amount and then lowers the cost.

- Q: How to do inventory management

- You can try to go through the river software, we are doing the plate are used it.

- Q: Ecological wood plate prices

- Ecological wood panels are mainly ecological wood plank, ecological wood sound-absorbing panels, ecological wood small round panels, ecological wood panels, etc., the price varies according to product models are different, and the indoor with the price of outdoor ecological wood is not the same , The specific can understand the Riling ecological wood

- Q: My family ready to decorate, my friend recommended to me Lili She Lug plate, I do not know how this brand?

- This brand of plates have not heard of, should be a regional brand, it is recommended to use the well-known brands of the plate, like the king coconut, Moganshan, the new millennium and the like, these are more well-known domestic plate brand. Which king coconut of the paint plate is the national standard drafting unit!

- Q: What kind of timber is the high grade guitar?

- General top or advanced guitar wood selection surface is not particularly large, generally fixed in several kinds of wood, the production of guitar is very much but in the high-grade guitar selection, the available is not particularly much (in addition to some special Creative thinking of the producer's whim). Here I give you a closer look: panel: Spruce spruce sound grain good, penetrating, cool and bright. It is the first choice for most guitar panels, which is made of German-made (Sicilia spruce) and Canadian (Inman Spruce), with high density, woody charm, hard and easy to process. The Representative Brand: H.Romannillos, Hauser, Martin, Taylor, Gibson. Cedar cedar sound deep atmosphere, strong sense of sticky, soft and warm. It is good for American-made (western pine) and Canada (Ingersel Cedar), high density, fine grain and delicate, easy to process, and now many guitar makers prefer wood (easy to process). ...). On behalf of the brand: Greg.Smallman, Kenny.Hill, Takamine, King of Recording.

- Q: What kind of sheet is usually used in the wardrobe?

- Ecological board, fir board

- Q: Wardrobe to choose how thick the plate

- Wardboard cabinet plate is probably distributed; back plate 9mm, layer board 12mm, side panels are divided into 12mm and 24mm, bookcases and usually with 24mm, desk with 32mm! As you ask the sliding plate, usually the wave board, the thickness is 9mm, but also useful flat panel, the thickness is 12mm! That the door of the sliding door, that is, it has a titanium alloy size! Out of range you are not installed!

- Q: Home decoration do want to do the solid wood doors and cabinets, but also the package side of the package, but it is said that easy to deformation if the use of solid wood inside the panel with solid wood panels, then it will stick with environmental performance as solid wood, but not easy to deform it to see the market with pine materials A lot of everyone is what advice next week on the woodworking undecided ah.

- I am in the harbor of the easy, Jindian home that bought the board, 263 a camphor wood used to do the closet, the door I made to order. Carpenters do the door as the outside to buy good-looking, I think it, do the door with solid wood is not very good, easy to deformation. My colleagues use the solid wood board to do, the results just renovated, not married door on the deformation, but not great, maybe the carpenter's craft not work right I intend to go out to do, do at least better than to do, quality how we do not know, say that the door inside the basic we have also used their own carefully, basically did not say that is bad!

- Q: Calcium silicate board is what material

- Calcium silicate board as a new environmentally friendly building materials, in addition to the function of the traditional gypsum board, the more excellent performance of calcium silicate board and moisture resistance, the advantages of long life, a large number of industrial and commercial applications in the ceiling ceiling and partitions, Home decoration, furniture liner, billboard liner, ship compartment board, warehouse floor, network floor and tunnel and other indoor works of the wall. It is a high-quality high-grade cement as the base material, and with natural fiber reinforced, the advanced production process molding, pressure, high temperature steaming and other special technology and made, is a good performance of the new building and industrial Plate of its products fire, moisture, noise, insect moth, durable. Is the ceiling, cut off the ideal decorative plate.

- Q: Our company wants to carry out timber, furniture import and export business, now the business license has the right to import timber and trade registration form and customs receipt and delivery certificate, want to know also need those departments for approval. If the import of timber need to quarantine and other departments approved it? Please help out, thank you first here!

- Imported wood and furniture are different. Timber import normal declaration Check the words do not need special approval is to provide foreign official phytosanitary certificate Note that there is no soil and bark. Provide certificate of origin.

Send your message to us

Floor Decking Steel Panel good quality with high standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords