Neoly Geocells Fiberglass Geogrid with CE Certificate and Free Samples

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

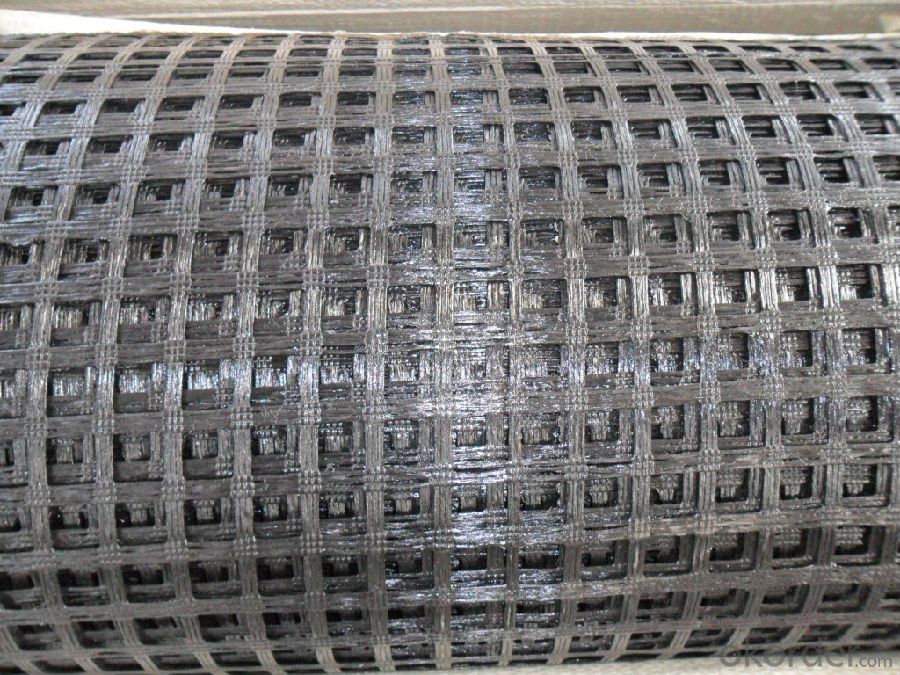

Fiberglass Geogrid with CE Certificate and Free Samples

Description Of Fiberglass Geogrid with CE Certificate and Free Samples:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Main Features of Fiberglass Geogrid with CE Certificate and Free Samples:

1.High tensile strength, low elongation.

2.No long-term creep: the product can keep for a long time performance.

3.Thermal stability: fiber glass melting temperature above 1000 ℃.

4.The compatibility with asphalt.

5.Physical and chemical stability.

Specifications of Fiberglass Geogrid with CE Certificate and Free Samples:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid with CE Certificate and Free Samples:

Strengthen bitumen concrete roadway and reduce and prevent various kinds of reflection gaps on roadway.

1.Suitable for highway, railway, airport road of subgrade enhancement.

2.Suitable for the large parking lot and port freight yard that the foundations of the permanent load increased.

3.Suitable for railway, highway slope protection.

4.Suitable for culverts.

5.Suitable for the uniaxial tensile geogrid reinforced soil secondary enhancement, after further enhance soil, prevent soil erosion.

6.Mining, tunnel reinforcement.

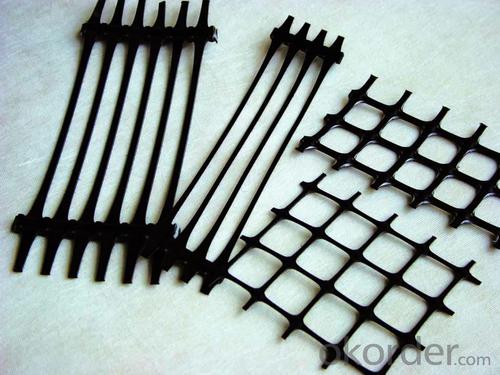

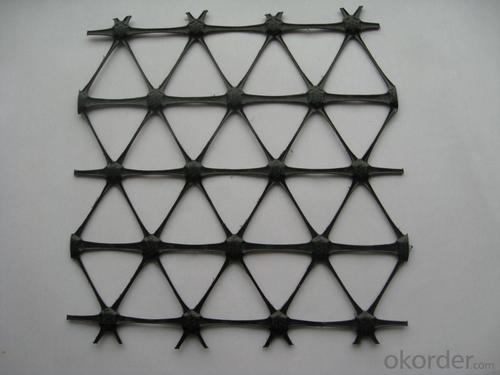

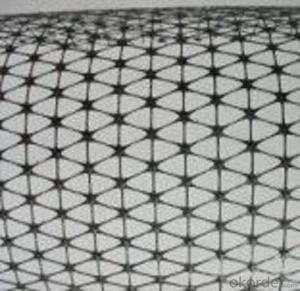

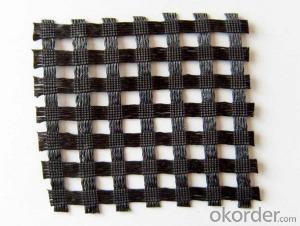

IMages of Fiberglass Geogrid with CE Certificate and Free Samples:

FAQ of Fiberglass Geogrid with CE Certificate and Free Samples:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What is the typical weight of a geogrid roll?

- The typical weight of a geogrid roll can vary depending on the specific type and size of the geogrid. However, on average, geogrid rolls can weigh anywhere from 50 to 500 pounds.

- Q: What is the single geogrid 60kN/m

- Should be a one-way geogrid, 60kN/m grid strength

- Q: Can geogrids be used in foundation stabilization?

- Yes, geogrids can be used in foundation stabilization. They are commonly used in civil engineering and construction projects to reinforce soil and improve the stability of foundations. Geogrids are typically installed horizontally or vertically within the soil to distribute loads and prevent soil movement, thereby enhancing the overall stability and performance of foundations.

- Q: Can geogrids be used in stormwater management applications?

- Yes, geogrids can be used in stormwater management applications. Geogrids are commonly used to reinforce and stabilize soil in various construction projects, including stormwater management systems. They can be used to enhance the strength and stability of retaining walls, embankments, and slopes, which are essential components of stormwater management systems. Additionally, geogrids can help reduce soil erosion and improve drainage, making them a valuable tool in stormwater management.

- Q: How many square meters of steel plastic geogrid inspection

- It is about ten thousand square meters.

- Q: Are geogrids effective in reducing soil settlement?

- Yes, geogrids are effective in reducing soil settlement.

- Q: What are the design considerations for geogrid reinforcement?

- Some of the design considerations for geogrid reinforcement include the type and strength of the geogrid material, the desired level of reinforcement, the soil conditions and properties, the anticipated loads and stresses, the environmental conditions, and the installation and maintenance requirements. Additionally, factors such as cost, availability, and compatibility with other materials and construction methods should also be taken into account during the design process.

- Q: Engineering effect of steel plastic geogrid

- 1, high strength, small creep, adapt to all kinds of soil environment, can fully meet the use of high grade highway retaining wall.2, can effectively improve the reinforced bearing surface, occlusal function, interlocking greatly improve foundation bearing capacity, effectively restrain the soil lateral displacement of reinforced foundation, stable performance.3, compared with the traditional grid has greater strength, strong bearing capacity, corrosion resistance, anti-aging, friction coefficient, perforated uniform, convenient construction, long service life and other characteristics.

- Q: How do geogrids improve the performance of geosynthetic drainage systems?

- Geogrids improve the performance of geosynthetic drainage systems by providing additional structural support and stability. They enhance the load-bearing capacity of the system, preventing soil erosion and promoting effective water flow. Geogrids also distribute the weight evenly across the system, reducing the risk of localized failures and improving long-term durability.

- Q: What is the market price of the geotechnical grid in 2017?

- (4) the first layer of geogrid paved, began to fill with second layers of 0.2m in thick sand (coarse), the method of sand transport to the site: car unloading to the subgrade side, then put forward to push the bulldozer, within 2 meters on both sides of the subgrade filling after 0.1M, the first layer of geogrid fold up and then fill in 0.1 meters in the sand (coarse), from both sides to the middle filling and advance, prohibit all machinery without filling (coarse sand) of Geogrid on traffic operation, it can guarantee the geogrid is smooth, does not play drums, do not wrinkle, stay in the second layer (coarse) after the formation of sand, the level of measurement, to prevent uneven filling thickness, leveling and correct use of vibratory roller 25T static pressure two times.

Send your message to us

Neoly Geocells Fiberglass Geogrid with CE Certificate and Free Samples

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords