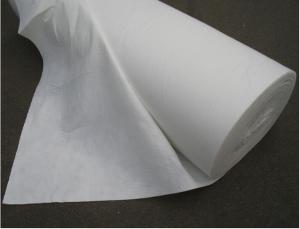

Permeable Needle Punched Short Fiber Nonwoven Polyester Geotextile Membrane 100g for Construction Use

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Needle Punched Short Fiber Nonwoven Polyester Geotextile 100g for Construction Use

1. Specifications of Needle Punched Short Fiber Nonwoven Polyester Geotextile 100g for Construction Use

Specifications: 100gsm-800gsm

Width: 1-6m

Length: 50-100m or as request

Property: good flexibility, permeability, filtration, separation and easy for consturction

2. Technicial Data of Needle Punched Short Fiber Nonwoven Polyester Geotextile 100g for Construction Use

No. | Item | Specification | Note | ||||||||||

Mass per square meter g/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | ||

1 | Weight Variation % | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

2 | Thickness mm | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width Variation % | -0.5 | |||||||||||

4 | Breaking Strength KN/m | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD and CD |

5 | Elongation at Break % | 25 ~ 100 | |||||||||||

6 | CBR Mullen Burst Strength KN | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

7 | Sieve Size 090 mm | 0.07 ~ 0.2 | |||||||||||

8 | Vertical Permeability Coefficient cm/s | k× (0.1 ~ 0.001) | k=1.0-9.9 | ||||||||||

9 | Tear Strength KN | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | MD and CD |

Needle punched geotextile after treatment method | |||||||||||||

3. Packing of Needle Punched Short Fiber Nonwoven Polyester Geotextile 100g for Construction Use

4. Application of Needle Punched Short Fiber Nonwoven Polyester Geotextile 100g for Construction Use

In the area of highway, railway, dam, reclamation for filtration, separation drainage and protection.

- Q: Is there a geotextile in the center of the expressway

- This is needed, the manufacturer answers

- Q: How do geotextiles contribute to erosion control on slopes?

- Geotextiles contribute to erosion control on slopes by acting as a barrier that prevents soil erosion. They are typically placed on the surface of slopes to stabilize the soil and prevent the movement of sediment. The geotextiles help to reduce the velocity of water runoff, allowing it to infiltrate into the soil rather than carrying away the soil particles. Additionally, geotextiles can promote vegetation growth by providing a stable surface for plant roots to anchor, further minimizing erosion on slopes.

- Q: What are the factors to consider when designing geotextile tubes for dewatering?

- When designing geotextile tubes for dewatering, several factors need to be considered. These include the type and characteristics of the sediment being dewatered, the desired dewatering efficiency, the required size and number of tubes, the hydraulic conditions, the site-specific environmental factors, and the available equipment and resources. Additionally, factors such as the strength and permeability of the geotextile material, the potential for clogging, and the long-term stability of the dewatering system should also be taken into account.

- Q: Can geotextiles be used in coastal erosion control?

- Yes, geotextiles can be used in coastal erosion control. They are commonly used to stabilize slopes, reinforce soil, and protect shorelines from erosion caused by waves and currents. Geotextiles can help to reduce the impact of wave energy, trap sediment, and promote vegetation growth, ultimately helping to prevent coastal erosion.

- Q: Bentonite waterproof blanket and geotextile pond construction which is good

- Impermeable membrane construction convenience, waterproof blanket and high prices, the effect is better than impermeable membrane

- Q: How do geotextiles improve the performance of shorelines?

- Geotextiles improve the performance of shorelines by providing erosion control, stabilizing the soil, and promoting vegetation growth. These synthetic fabrics act as a barrier that prevents soil erosion caused by waves, tides, and currents. Geotextiles also help to distribute hydraulic pressure, reducing the impact of water on shorelines. Additionally, they facilitate the growth of vegetation by retaining moisture and providing a stable base for plant roots, further reinforcing the shoreline and enhancing its overall performance.

- Q: What are the different geotextile permeability testing methods?

- There are several different geotextile permeability testing methods, including the constant head method, falling head method, and gradient ratio method.

- Q: What is the latest price of geotextile?

- Per ton of national standard short geotextile 7000-8000 yuan, filament geotextile per ton - yuan.

- Q: How do geotextiles help with filtration in drainage systems?

- Geotextiles assist with filtration in drainage systems by acting as a barrier that allows water to pass through while preventing the passage of fine particles and sediment. This helps to maintain the integrity and effectiveness of the drainage system by preventing clogging and promoting efficient water flow.

- Q: What are the different guidelines for geotextile installation in erosion control projects?

- There are several guidelines that need to be followed for geotextile installation in erosion control projects. Firstly, the geotextile must be placed on a properly prepared surface to ensure maximum effectiveness. The fabric should be tightly stretched and secured to prevent any movement or shifting. Additionally, the edges of the geotextile should overlap and be properly sealed to create a continuous barrier. It is also important to avoid any wrinkles or folds in the fabric as these can compromise its performance. Finally, regular inspection and maintenance should be conducted to ensure the geotextile remains intact and functional over time.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Permeable Needle Punched Short Fiber Nonwoven Polyester Geotextile Membrane 100g for Construction Use

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords