Needle Punched Geotextile Reinforced Linear Low-Density Polyethylene Geomembrane for Waste Liquids

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

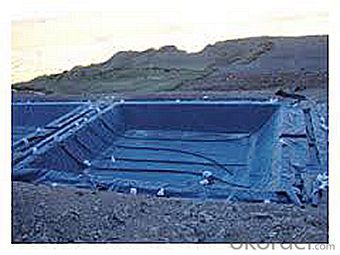

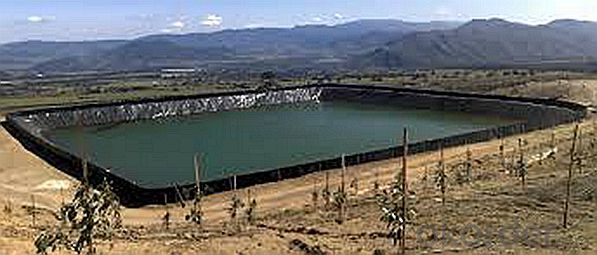

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

Specifications

professional,satisfied service , the most competitive price , the best product ,do as your requirement

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in contaminated soil?

- Yes, geotextiles can be used in contaminated soil. Geotextiles are often used in contaminated soil remediation projects to provide separation, filtration, and reinforcement. They help to control the migration of contaminants, prevent soil erosion, and improve the stability of the soil. By effectively containing and treating the contaminants, geotextiles contribute to the overall success of soil remediation efforts.

- Q: How are geotextiles used in road construction?

- Geotextiles are used in road construction to enhance the structural integrity and lifespan of the road. They are placed between the subgrade and the base course to prevent soil erosion, improve drainage, and provide separation and filtration. Geotextiles also help to distribute loads and reduce cracking and rutting in the road surface.

- Q: What are the different geotextile installation techniques for roadways?

- There are several different geotextile installation techniques for roadways, including the overlay method, the trench method, and the sandwich method. - The overlay method involves placing the geotextile directly on top of the existing soil or subgrade before adding the new road material, such as asphalt or concrete. This technique helps to separate the soil layers and prevent the mixing of materials, providing stability and reducing the risk of road failure. - The trench method involves excavating a trench along the road alignment and placing the geotextile in the trench before backfilling it with soil or aggregate. This technique is commonly used for drainage applications, as the geotextile acts as a filter to prevent fine particles from clogging the drainage system, while allowing water to flow through. - The sandwich method is a combination of the overlay and trench methods. It involves placing a layer of geotextile between the existing soil and the new road material, as well as placing another layer of geotextile on top of the new road material. This technique provides additional reinforcement and separation, enhancing the overall performance and durability of the roadway. Overall, the choice of geotextile installation technique depends on the specific requirements and conditions of the road project, such as soil type, traffic load, and drainage needs.

- Q: What are the challenges associated with geotextile installation?

- There are several challenges associated with geotextile installation. One of the main challenges is ensuring proper placement and alignment of the geotextile material. This requires skilled labor and careful handling to prevent wrinkles, folds, or misalignment, which can compromise the effectiveness of the geotextile. Additionally, securing the geotextile in place can be difficult, especially in areas with high winds or water flow. Adequate anchoring and fastening methods need to be employed to prevent movement or displacement of the geotextile. Another challenge is the potential for damage during installation, such as tearing or puncturing the material. This can occur due to equipment, sharp objects, or improper handling. Finally, ensuring proper overlap and seam integrity is crucial to maintain the continuity and strength of the geotextile system. Overall, geotextile installation requires careful planning, skilled labor, and attention to detail to overcome these challenges and achieve the desired performance.

- Q: What are the different geotextile installation techniques for erosion control blankets?

- There are several geotextile installation techniques for erosion control blankets, including trench and backfill, stake and tension, and anchor and pin. Trench and backfill involves digging a trench along the slope, placing the erosion control blanket in the trench, and then backfilling it with soil. Stake and tension involves driving stakes into the ground at regular intervals and then securing the erosion control blanket to the stakes with tensioning devices. Anchor and pin involves using anchors or pins to secure the erosion control blanket directly to the ground. The specific technique used depends on the slope conditions and project requirements.

- Q: Cement concrete bridge is a film curing or geotextile maintenance

- Commodity concrete pouring is completed, should be in the slurry after grinding as soon as possible to cover and sprinkler conservation. Commodity concrete bridge deck with full coverage of sprinkler conservation methods, covering materials with two sticky one geotextile, every 1t sprinkler once, to ensure the quality of conservation, to prevent cracks.

- Q: What are the factors to consider when selecting geotextiles for mining applications?

- When selecting geotextiles for mining applications, several factors need to be taken into consideration. These factors include the type and characteristics of the soil or rock, the load and stress exerted on the geotextile, the required strength and durability of the geotextile, the desired filtration and drainage properties, the potential for chemical exposure or environmental degradation, and the cost-effectiveness of the geotextile solution. Additionally, the availability and accessibility of the geotextile, as well as any regulatory requirements or industry standards, should also be considered in the selection process.

- Q: Geogrid Specifications TGSG40-40 What does it mean?

- I tell you, TGSG40-40: two-way stretch plastic geogrid, its vertical, horizontal strength indicators are not less than 40KN, to meet the national standards. We are a professional geogrid manufacturer, you have any questions you can call: 13879 22308, also welcome you to visit the company. Thank you!

- Q: 3923.1 why not apply to geotextiles

- Geotextile price, geomembrane price, composite geomembrane price can be found tgcl1123 to see

- Q: What are the key properties to consider when evaluating geotextiles?

- When evaluating geotextiles, some key properties to consider include the strength and durability of the material, its filtration and drainage capabilities, its resistance to UV degradation and chemical exposure, as well as its permeability and compatibility with the intended application. Additionally, factors like cost-effectiveness, ease of installation and maintenance, and environmental sustainability should also be taken into account.

Send your message to us

Needle Punched Geotextile Reinforced Linear Low-Density Polyethylene Geomembrane for Waste Liquids

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords