Geotextile Fabric Under Gravel Needle Punched Polyester/Polypropylene Nonwoven Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Needle Punched Polyester/Polypropylene Manufacturer Nonwoven Fabric Non Woven Geotextile

Desciriptions:

Polyester Nonwoven Geotextile Professioal Waterproof Geotextiles. A woven geotextiles is an economical solution for any civil engineering applications.Made from PP (polypropylene) or PET (polyester) short fiber by nonwoven needle punched manufacturing process, it has isolation, filtration, drainage, reinforcement, protection and maintenance etc. function. It separates, stabilizes, and reinforces soils and allows for filtration Woven geotextiles are manufactured by extruding polypropylene film and then slitting the film into individual yarns which are then woven to form the geotextiles.

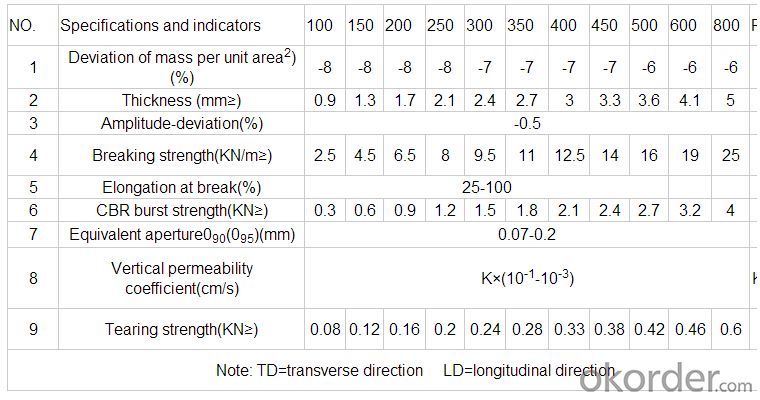

Specifications and Technical datas:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

1. Good flexibility, resistant to corrosion, resistant to acids and alkalis, anti-oxidation

2. Separation, filtration, drainage, reinforcement, protection, and maintenance function

Details of our products:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

1. The outer package: black or white woven geotextile.or we can make the package as your requst.

2. Different tgram/ roll size for different qty in the same containers.

3. Roll size: 3.95m*200 for container

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: How do geotextiles help with sediment control in construction sites?

- Geotextiles are used in construction sites to help with sediment control by acting as a barrier that traps sediment and prevents it from being washed away by water runoff. These permeable fabrics allow water to pass through while retaining the sediment, reducing erosion and preventing pollution of nearby water bodies.

- Q: How do geotextiles contribute to the stability of landfill slopes?

- Geotextiles contribute to the stability of landfill slopes by providing reinforcement and erosion control. They are placed between the different layers of soil or waste materials in the landfill, acting as a barrier to prevent soil erosion and the loss of landfill materials. The geotextiles also help to distribute loads across the slope, increasing its overall stability and preventing slope failures. Additionally, they improve drainage by allowing water to pass through, reducing the risk of pore water pressure buildup which can further destabilize the slope.

- Q: What are the specifications for geotextiles in pond liner projects?

- The specifications for geotextiles in pond liner projects can vary depending on the specific requirements of the project. However, common specifications may include factors such as the desired strength, permeability, and durability of the geotextile material. Additionally, the specifications may also consider the desired weight, thickness, and UV resistance of the geotextile. Ultimately, these specifications are determined based on the specific needs and conditions of the pond liner project.

- Q: Do you need to suture the lower geotextile of composite geomembrane?

- Look at construction requirements

- Q: White geotextile surface from the particles?

- Hello, did not understand your problem, the general geotextile will not play a grain of ah

- Q: The amount of geotextile drainage of the drainage pipe, as well as the amount of gravel block ye count

- Are you talking about plastic blinds? do you need? I specialize in producing geotextile materials

- Q: Can geotextiles be used in coastal protection projects?

- Yes, geotextiles can be used in coastal protection projects. Geotextiles are permeable fabrics that can effectively control erosion and stabilize soil in coastal areas. They are commonly used to prevent sediment loss, promote vegetation growth, and provide shoreline protection against wave action. Geotextiles can be installed as a barrier or a filter to retain sediment and prevent erosion, making them a valuable tool in coastal protection projects.

- Q: Are geotextiles resistant to extreme temperatures?

- Yes, geotextiles are generally resistant to extreme temperatures. They are designed to withstand a wide range of environmental conditions, including high and low temperatures, without significant degradation or loss of performance.

- Q: Can geotextiles be used in coastal revetment works?

- Yes, geotextiles can be used in coastal revetment works. Geotextiles are commonly used as a component in coastal revetment systems to provide erosion control and stabilization. They can help to reinforce the soil, prevent erosion, and enhance the stability of the revetment structure.

- Q: How do geotextiles help with groundwater protection?

- Geotextiles function as a barrier or filter that helps protect groundwater by preventing the infiltration of contaminants into the underground water sources. They aid in separating different layers of soil and preventing the mixing of pollutants with the groundwater, thereby safeguarding the quality and purity of water resources.

Send your message to us

Geotextile Fabric Under Gravel Needle Punched Polyester/Polypropylene Nonwoven Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords