Nationnal Factory HRB500 Reinforcement Steel Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Nationnal Factory HRB500 Reinforcement Steel Bar

Description of HRB500 Reinforcement Steel Bar

1, Diameter: 5.5mm-10mm HRB500 Reinforcement Steel Bar

10m- 40mm HRB500 Reinforcement Steel Bar

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of HRB500 Reinforcement Steel Bar

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

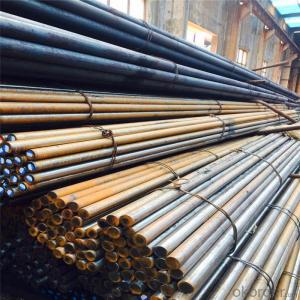

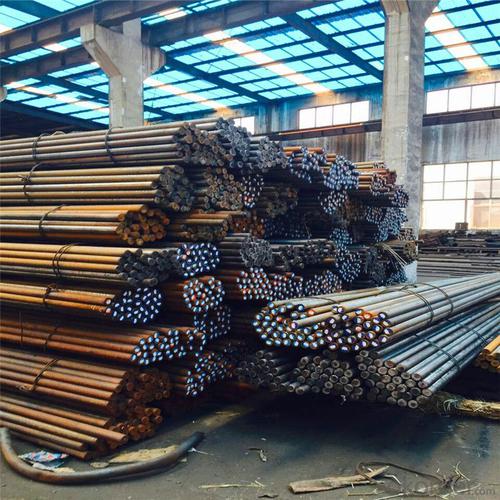

Products Show of HRB500 Reinforcement Steel Bar

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different surface coating methods used for special steel?

- Special steel can be enhanced and protected from environmental factors using various surface coating methods. These methods include: 1. Galvanizing: Zinc is applied to the steel surface, offering exceptional corrosion resistance. This can be achieved through hot-dip galvanizing or electroplating. 2. Electroplating: A thin layer of metals like chromium, nickel, or copper is deposited onto the steel surface using an electrochemical process. This improves appearance, wear resistance, and corrosion resistance. 3. Powder coating: Dry powder is applied to the steel surface, heated, and fused to create a protective layer. This provides durability, weather resistance, and aesthetic appeal. 4. Thermal spray coating: A heated or molten material is sprayed onto the steel surface, solidifying into a protective coating. Materials like metals, ceramics, and polymers are commonly used. 5. Paint coating: Painting is a widely used method for surface coating. Epoxy, polyurethane, or acrylic paints can be applied to protect against corrosion, chemicals, and UV radiation. 6. PVD coating: A thin film of materials like titanium nitride or diamond-like carbon is deposited onto the steel surface through vacuum deposition. PVD coatings enhance hardness, wear resistance, and appearance. 7. Anodizing: Primarily used for aluminum, anodizing can also be applied to special steel. It involves creating an oxide layer through an electrochemical reaction, improving corrosion resistance and providing a decorative finish. These surface coating methods are crucial for special steel as they enhance protection against corrosion, wear, and environmental factors. This ultimately extends the steel's lifespan and improves its performance. The choice of coating method depends on the specific requirements and desired properties of the steel.

- Q: What are the different methods of surface honing for special steel?

- Surface honing for special steel can be achieved through various methods, each with its own benefits and uses. Among the commonly employed techniques are: 1. Manual Honing: This approach entails the utilization of handheld honing tools, such as stones, sticks, or abrasive pads, to manually remove material from the steel's surface. Manual honing permits meticulous control and is often suitable for smaller or intricate components. 2. Machine Honing: Machine honing involves the use of specialized honing machines that automate the honing process. These machines typically feature rotating honing stones or abrasive belts, which eliminate material from the steel's surface. Machine honing is favored for larger or complex parts, as it ensures consistent and high-quality outcomes. 3. Diamond Honing: Diamond honing relies on diamond abrasives to eradicate material from the special steel's surface. Given that diamond is one of the hardest substances known, it is exceptionally effective for honing steel. This method is commonly employed in high-precision applications or instances where an exceedingly smooth surface finish is required. 4. Superfinishing: Superfinishing is a specialized honing process that achieves extremely fine surface finishes on special steel. It combines honing stones and abrasive pastes to remove minuscule amounts of material from the surface. Superfinishing is typically utilized in critical applications where surface roughness and dimensional accuracy are of utmost importance. 5. Lapping: Lapping is a honing method that employs a combination of abrasive particles and a rotating or vibrating tool to eliminate material from the steel's surface. It is particularly suitable for parts necessitating a very flat or parallel surface, such as bearings or sealing surfaces. 6. Electrochemical Honing: Electrochemical honing is a specialized process that employs an electric current to remove material from the special steel's surface. It is often employed for intricate or hard-to-reach surfaces, as it effectively eliminates material from areas inaccessible to other honing methods. To sum up, the various methods of surface honing for special steel encompass manual honing, machine honing, diamond honing, superfinishing, lapping, and electrochemical honing. Each method offers distinct advantages and applications, enabling precise control and the attainment of desired surface finishes and dimensional accuracy for special steel components.

- Q: What are the properties of maraging steel?

- Maraging steel is a type of high-strength steel known for its exceptional strength, toughness, and resistance to fatigue. It possesses a unique combination of properties such as high yield strength, excellent fracture toughness, and superior hardness. This steel also exhibits remarkable corrosion resistance and can withstand extreme temperatures. Additionally, maraging steel is highly weldable and machinable, making it suitable for a wide range of applications in industries such as aerospace, defense, and tooling.

- Q: What are the different methods of surface carburizing for special steel?

- Some of the different methods of surface carburizing for special steel include pack carburizing, gas carburizing, liquid carburizing, and plasma carburizing.

- Q: How is special steel recycled or disposed of?

- The material known as special steel, or alloy steel, is highly valuable and in great demand because of its unique properties and uses. When it comes to disposing of or recycling special steel, there are several methods available depending on the condition and quality of the material. Recycling is the most preferred and commonly used method for managing special steel. The recycling process involves gathering, organizing, and melting down the steel scrap so that it can be reused in the production of new steel products. This process helps to preserve natural resources, reduce energy consumption, and minimize waste. The initial step in recycling special steel involves collecting scrap or end-of-life products that contain this material. These sources can include discarded machinery, automotive parts, construction materials, and even old appliances. Once collected, the steel is sorted and separated from other materials, such as plastic, rubber, or non-ferrous metals, using various techniques like magnetic separation, eddy current separation, or manual sorting. After the sorting process, the steel scrap is sent to a specialized recycling facility, commonly referred to as a steel mill or foundry. Here, the scrap is melted down in large furnaces at extremely high temperatures. During this process, impurities and contaminants are removed, and alloying elements can be added to achieve the desired composition and properties of the steel. Once the steel has been melted and purified, it is cast into various forms such as ingots, billets, or slabs, which can then be used to manufacture new steel products. These products may include pipes, bars, plates, or even new machine parts, depending on the specific needs of the industry. When it comes to disposal, special steel should be seen as a valuable resource and not simply discarded as waste. However, in cases where the steel is irreparably damaged or contains hazardous materials, proper disposal methods must be followed. This typically involves seeking advice from specialized waste management companies that can handle the safe and environmentally friendly disposal of such materials. In conclusion, special steel is primarily recycled due to its high value and the various benefits associated with recycling. Through the processes of collection, sorting, and melting, special steel can be transformed into new products while conserving resources and minimizing waste. Proper disposal methods are only necessary in exceptional cases where recycling is not feasible or when dealing with damaged or hazardous materials.

- Q: How is nitriding steel used in the manufacturing of engine components?

- Nitriding steel is commonly used in the manufacturing of engine components due to its ability to enhance their performance and durability. The process of nitriding involves diffusing nitrogen into the surface of the steel, forming a hard and wear-resistant layer. This improves the component's resistance to corrosion, fatigue, and high temperatures, ultimately extending its lifespan and enhancing its overall performance in engine applications.

- Q: What are the different heat treatment methods used for special steel?

- There are several heat treatment methods used for special steel, including annealing, quenching, tempering, normalizing, and case hardening.

- Q: How does special steel contribute to the renewable energy sector?

- Special steel plays a crucial role in the renewable energy sector by enabling the construction of highly efficient and durable renewable energy infrastructure. It is used in the manufacturing of wind turbine components, solar panels, and hydroelectric power systems, among others. Its exceptional strength, corrosion resistance, and ability to withstand extreme conditions make it ideal for withstanding harsh weather and environmental factors. Additionally, special steel helps optimize energy conversion and transmission, ultimately improving the overall efficiency and reliability of renewable energy systems.

- Q: What are the requirements for special steel used in telecommunications infrastructure?

- The requirements for special steel used in telecommunications infrastructure include: 1. High strength: Special steel used in telecommunications infrastructure should have high tensile strength to withstand the heavy loads and stresses imposed on the structures. This ensures that the infrastructure remains stable and secure. 2. Corrosion resistance: As telecommunications infrastructure may be exposed to various environmental conditions, including moisture and chemicals, it is crucial for the special steel to have excellent corrosion resistance. This helps to protect the infrastructure from rust and deterioration, extending its lifespan. 3. Good weldability: Special steel used in telecommunications infrastructure should have good weldability to facilitate the construction and installation processes. This allows for easy joining of different components, ensuring a strong and reliable structure. 4. Durability: The special steel should be able to withstand the harsh conditions it may be exposed to over its lifetime. It should have high durability to resist fatigue, impact, and other external factors that could potentially compromise the integrity of the infrastructure. 5. Lightweight: While strength is important, special steel used in telecommunications infrastructure should also be lightweight. This enables easier transportation, handling, and installation of the components, reducing costs and time required for construction. 6. Fire resistance: Special steel used in telecommunications infrastructure should have good fire resistance properties to prevent the spread of fire and ensure the safety of the infrastructure and the surrounding areas. 7. Electrical conductivity: Telecommunications infrastructure often requires electrical grounding and bonding. Therefore, special steel used in these applications should have good electrical conductivity properties to ensure effective grounding and minimize electrical interference. Meeting these requirements ensures that the special steel used in telecommunications infrastructure can provide the necessary structural integrity, longevity, and performance to support reliable and efficient communication networks.

- Q: What are the limitations of using special steel in high-temperature applications?

- The limitations of using special steel in high-temperature applications include its susceptibility to oxidation and corrosion, reduced mechanical strength at elevated temperatures, and potential for thermal expansion and distortion. Additionally, special steel may be expensive and difficult to obtain, limiting its practicality in certain applications.

Send your message to us

Nationnal Factory HRB500 Reinforcement Steel Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords