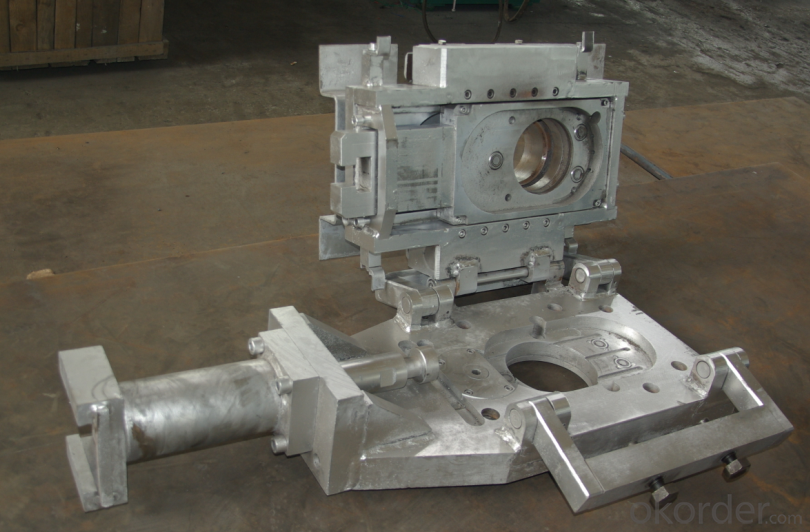

Monolithic Refractories Zirconia Slide Gate Nozzle Upper and Lower Nozzle Brick for Iron and Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: | Shandong, China (Mainland) | Shape: | Plate | Material: | SiC,Zirconia,corundum |

SiO2 Content (%): | 0.2 | Al2O3 Content (%): | 0.3 | MgO Content (%): | less |

CaO Content (%): | less | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | less |

SiC Content (%): | 7% | Model Number: | B60,B50,C40 | Brand Name: | Shikai |

Density: | 3.0g/cm3 | Al2O3: | 85% | Compressive strength: | 100Mpa |

Apparent Porosity: | 10% | Refractoriness: | more than 1790℃ | Advantage: | high refractoriness, good thermal shock resistance, erosion resistance |

Usage: | steel plant ladle and tundish | Packing: | carton,pallets | C+SiC: | 5% |

product: | slide gate,upper nozzle,lower nozzle |

Packaging & Delivery

Packaging Details: | cartons,plastic film and pallets,wooden box,As requested. |

Delivery Detail: | within 30days after get your order |

Ladle nozzle brick,upper nozzle brick,lower nozzle brick

Product information:

1.Advantage:high refractoriness, good thermal shock resistance, erosion resistance and

scouring resistance, small hole diameter change, long service life, etc.

2.Product data:

Burnt Slide gate

Item B60,B50,C40type | Al-C Slide Gate | Al-Zr-C Slide Gate | ||||||

AlC-70 | AlC -75 | AlC -80 | AlC-85 | AlC -86 | AlZrC -70 | AlZrC-75 | AlZrC -77 | |

Al2O3,% | 70 | 75 | 80 | 85 | 86 | 70 | 75 | 77 |

C+SiC,% | 7 | 7 | 5 | 5 | 4 | 7 | 7 | 7 |

ZrO2,% | - | - | - | - | - | 6 | 6 | 2.5 |

A.P.,% max | 10 | 10 | 10 | 10 | 7 | 10 | 10 | 10 |

B.D.,g/cm3 | 2.8 | 2.9 | 2.9 | 3.0 | 2.95 | 3.00 | 3.05 | 2.90 |

C.C.S., MPa min | 65 | 70 | 100 | 100 | 100 | 110 | 115 | 100 |

Unburned compound AlC Slide gate

Item B60,B50,C40type | Al-C Slide Gate | ||||

AlC-70A | AlC-75A | AlC-80A | AlC-85A | AlC-86A | |

Al2O3,% | 70 | 75 | 80 | 85 | 86 |

C,% | 7 | 7 | 5 | 5 | 4 |

A.P.,% max | 10 | 10 | 8 | 10 | 7 |

B.D. g/cm3 min | 2.8 | 2.9 | 3.0 | 3.0 | 2.95 |

C.C.S., MPa min | 65 | 70 | 100 | 100 | 100 |

zirconium core :

Item | ZN- 65 | ZN- 70 | ZN- 75 | ZN- 80 | ZN- 85 | ZN- 90 | ZN- 93A | ZN- 93B | ZN- 93C | ZN- 93D | ZN- 95A | ZN- 95B | ZN- 96 |

ZrO2(%) | ≥65 | ≥70 | ≥75 | ≥80 | ≥85 | ≥90 | ≥93 | ≥93 | ≥93 | ≥93 | ≥95 | ≥95 | ≥96 |

Bulk density (g/cm3) | ≥3.8 | ≥3.8 | ≥3.9 | ≥4.0 | ≥4.1 | ≥4.3 | ≥5.1 | ≥4.9 | ≥4.7 | ≥4.4 | ≥4.6 | ≥5.2 | ≥5.2 |

Apparent Porosity(%) | ≤23 | ≤22 | ≤22 | ≤20 | ≤20 | ≤20 | ≤13 | ≤15 | ≤18 | ≤20 | ≤20 | ≤9 | ≤5.6 |

Thermal shock resistance (cycles)(1100℃,water cooling) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >8 | >10 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do monolithic refractories withstand the chemical attacks in copper smelting applications?

- Due to their unique properties and composition, monolithic refractories are capable of enduring chemical attacks in copper smelting applications. These refractories are specifically engineered to resist the harsh and corrosive environment found in copper smelting processes. To begin with, monolithic refractories are crafted from high-quality materials such as alumina, silica, and magnesia. These materials possess high melting points and chemical stability. Carefully selected, they are able to withstand the corrosive effects of copper smelting, including the presence of sulfur compounds and acidic gases. The refractory's composition also includes various additives and bonding agents that enhance its resistance to chemical attacks. In addition, monolithic refractories exhibit exceptional thermal shock resistance. This means they can withstand rapid temperature changes without cracking or spalling. In copper smelting applications, where extreme temperatures are involved, this refractory quality is crucial in preventing the formation of cracks and ensuring long-term performance. Furthermore, monolithic refractories possess a dense and compact structure. This structure serves as an effective barrier against the infiltration of molten copper and other corrosive substances. By preventing the penetration of chemical attacks, the refractory lining's durability and longevity are ensured. Moreover, monolithic refractories offer superior erosion resistance. This is particularly important in copper smelting applications, where high-velocity gases and flows of molten metal can cause erosion of the refractory lining. The refractory's erosion resistance prevents the degradation of the lining and maintains its structural integrity. In conclusion, monolithic refractories are specially designed to withstand the chemical attacks encountered in copper smelting applications. Through the use of high-quality materials, the incorporation of additives, and the possession of excellent thermal shock resistance, density, and erosion resistance, these refractories provide a reliable and durable lining that can endure the harsh conditions of copper smelting processes.

- Q: How are monolithic refractories inspected and tested for quality assurance?

- Monolithic refractories are inspected and tested for quality assurance through various methods. Visual inspections are conducted to check for any visible defects such as cracks, spalling, or other physical damages. In addition, non-destructive testing techniques like ultrasonic testing and X-ray inspection are used to detect any internal flaws or inconsistencies in the refractory material. Furthermore, mechanical testing such as compression and flexural strength tests are performed to evaluate the mechanical properties of the monolithic refractories. These inspections and tests ensure that the refractories meet the required quality standards and can withstand the harsh operating conditions they are designed for.

- Q: How do monolithic refractories improve the lining of converters and refining vessels?

- Monolithic refractories enhance the lining of converters and refining vessels by providing superior thermal insulation, chemical resistance, and structural integrity. They eliminate the need for bricklaying, offering a seamless lining with reduced joints, thereby minimizing heat loss and ensuring efficient heat transfer. Additionally, monolithic refractories are highly resistant to the corrosive effects of molten metals and slag, prolonging the lifespan of the lining. Their flexibility enables easy installation and repair, resulting in reduced downtime and improved overall performance of converters and refining vessels.

- Q: How do monolithic refractories withstand the chemical attacks in aluminum furnace applications?

- Monolithic refractories are able to withstand chemical attacks in aluminum furnace applications due to their unique composition and properties. These materials are designed to have high resistance to the corrosive effects of molten aluminum and other chemicals present in the furnace environment. Firstly, monolithic refractories are made from a combination of different minerals, such as alumina, silicon carbide, and zirconia, which have high melting points and excellent chemical stability. These minerals act as a barrier between the corrosive substances and the underlying structure, preventing them from penetrating or damaging the refractory lining. Additionally, monolithic refractories are typically formulated with high levels of alumina, which provides them with exceptional resistance to chemical attacks. Alumina has a strong affinity for oxygen, forming a stable oxide layer on the surface of the refractory material, acting as a protective barrier against corrosive elements. This oxide layer also helps to reduce the rate of penetration of corrosive substances into the refractory lining. Moreover, monolithic refractories are often designed with a dense microstructure and low porosity. This ensures that there are fewer pathways for the corrosive substances to penetrate and attack the refractory material. The denser the material, the less susceptible it is to chemical attacks. Furthermore, monolithic refractories can be further enhanced by adding additives or binders that improve their resistance to chemical attacks. These additives can include various organic or inorganic materials that provide additional protection against corrosive substances. Overall, monolithic refractories are specifically engineered to withstand the harsh conditions of aluminum furnace applications. Their unique composition, high alumina content, dense microstructure, and resistance-enhancing additives all contribute to their ability to withstand chemical attacks and prolong the lifespan of the refractory lining in aluminum furnaces.

- Q: How are monolithic refractories used in the iron and steel industry?

- Due to their exceptional performance and versatility, monolithic refractories are widely utilized in various applications within the iron and steel industry. Composed of a uniform material, these refractories serve as seamless linings in high-temperature environments. In the iron and steel industry, the significance of monolithic refractories cannot be overstated as they play a crucial role in multiple stages of the manufacturing process. A primary application is seen in the blast furnace, where the inside of the furnace is lined with monolithic refractories. This lining is exposed to exceedingly high temperatures and harsh chemical reactions. By providing excellent thermal insulation and resistance to chemical attack, monolithic refractories ensure the durability and longevity of the blast furnace. Another crucial application is witnessed in the steelmaking process, where monolithic refractories are used to line the ladles and tundish, utilized for transporting and pouring molten steel. These refractories are specially designed to withstand the corrosive nature and high temperatures of the molten steel, thus preventing contamination and guaranteeing the quality of the final product. Furthermore, monolithic refractories find application in various ancillary equipment and structures within the iron and steel industry. They are employed in furnaces, kilns, and other heat treatment systems to provide insulation and maintain high-temperature conditions. Additionally, they are used in the construction of chimneys, exhaust ducts, and other exhaust systems, where they offer thermal insulation and resistance against corrosive gases. Overall, the vital role played by monolithic refractories in the iron and steel industry lies in their ability to provide high-temperature insulation, chemical resistance, and durability. They optimize the production process, enhance energy efficiency, and ensure the quality of the final product. With their exceptional performance and versatility, monolithic refractories have become an indispensable component within the iron and steel manufacturing industry.

- Q: How do monolithic refractories contribute to the quality of iron and steel products?

- Monolithic refractories play a crucial role in the production of high-quality iron and steel products. They provide superior resistance to extreme temperatures, chemical reactions, and mechanical stress in the production process. By maintaining the integrity of furnaces, ladles, and other equipment, monolithic refractories ensure consistent heat distribution and prevent contamination, resulting in improved product quality. Additionally, their ability to withstand thermal shock and erosion prolongs the lifespan of the refractory linings, reducing downtime and enhancing overall efficiency.

- Q: What are monolithic refractories and how are they different from other refractory materials?

- Monolithic refractories are a type of refractory material that is produced and applied in a single, unified form. Unlike other refractory materials, such as bricks or tiles, monolithic refractories are not pre-formed into specific shapes or sizes. Instead, they are generally composed of a mix of aggregates, binders, and additives, which are then installed in place and cured to form a solid, dense structure. One key difference between monolithic refractories and other refractory materials is their versatility and ease of installation. Traditional refractory bricks or tiles require skilled labor and careful assembly to create a lining or structure. Monolithic refractories, on the other hand, can be poured, sprayed, or gunned into place, allowing for a much faster and more efficient installation process. This makes them particularly suitable for complex shapes or areas that are difficult to access. Another difference lies in the physical properties of monolithic refractories. While bricks and tiles are typically characterized by their high mechanical strength and resistance to thermal shock, monolithic refractories can be tailored to exhibit a wide range of properties. They can be engineered to have excellent thermal insulation, superior corrosion resistance, or enhanced abrasion resistance, depending on the specific application requirements. This flexibility makes monolithic refractories suitable for a variety of industries, including steel, cement, glass, and petrochemical. Furthermore, monolithic refractories have the advantage of being able to expand and contract with temperature changes, unlike rigid brick structures. This thermal flexibility helps to minimize cracking and damage caused by thermal cycling, prolonging the lifespan of the refractory lining. Additionally, monolithic refractories offer better refractory integrity and reduced joint failure, as there are no seams or weak points that can be susceptible to thermal stresses. In summary, monolithic refractories are a versatile and convenient type of refractory material that can be customized to meet specific application requirements. Their ease of installation, thermal flexibility, and tailor-made properties make them distinct from other refractory materials such as bricks or tiles.

- Q: Can monolithic refractories be used for the lining of blast furnace runners and troughs?

- Yes, monolithic refractories can be used for the lining of blast furnace runners and troughs. Monolithic refractories are a type of refractory material that is composed of a single, homogeneous structure, as opposed to traditional refractory bricks that are made by assembling individual units. Monolithic refractories offer several advantages for lining blast furnace runners and troughs. Firstly, they have excellent thermal shock resistance, which is crucial in this application as the lining is subjected to extreme temperature fluctuations. Monolithic refractories also have good resistance to chemical attack from the molten metal and slag, which helps to prolong the lining's lifespan in the harsh working environment of blast furnaces. Furthermore, monolithic refractories can be easily installed in complex shapes and structures, allowing for greater flexibility in designing the lining of blast furnace runners and troughs. This ease of installation also leads to reduced downtime during maintenance and repair, as monolithic refractories can be quickly and efficiently applied. In summary, monolithic refractories are a suitable choice for lining blast furnace runners and troughs due to their thermal shock resistance, chemical resistance, and ease of installation. Their use can help to improve the longevity and performance of these critical components in blast furnace operations.

- Q: How do monolithic refractories contribute to the reduction of heat loss in ladles and tundishes?

- Monolithic refractories play a crucial role in reducing heat loss in ladles and tundishes. These refractories are designed to provide excellent thermal insulation properties, which help to minimize the transfer of heat from the molten metal to the surrounding environment. One of the key factors contributing to heat loss in ladles and tundishes is conduction, where heat is transferred through direct contact with the refractory lining. Monolithic refractories are specifically engineered to have low thermal conductivity, meaning they are efficient at reducing heat transfer through conduction. This helps to maintain the desired temperature of the molten metal for longer periods, ultimately reducing energy consumption and improving overall process efficiency. Furthermore, monolithic refractories also aid in reducing heat loss through radiation. These refractories have high emissivity, which means they emit a significant amount of thermal radiation. This emitted radiation helps to create a heat shield around the molten metal, preventing the loss of heat to the surroundings. By effectively trapping the radiant heat, monolithic refractories contribute to maintaining the desired temperature in ladles and tundishes, thereby minimizing heat loss. In addition to their thermal insulation properties, monolithic refractories also offer excellent resistance to thermal shock and mechanical stress, ensuring they remain intact and functional in the harsh operating conditions of ladles and tundishes. This durability further contributes to the reduction of heat loss by preventing any cracks or gaps in the refractory lining that could facilitate heat transfer. In summary, monolithic refractories significantly contribute to the reduction of heat loss in ladles and tundishes by minimizing heat transfer through conduction and radiation. Their thermal insulation properties, combined with their resistance to thermal shock and mechanical stress, help to maintain the desired temperature of the molten metal, improve energy efficiency, and enhance the overall performance of these metallurgical vessels.

- Q: What are the specific requirements of monolithic refractories for soaking pit applications?

- Monolithic refractories for soaking pit applications must meet several specific requirements. Firstly, they need to withstand high temperatures and thermal cycling. This means they must be able to endure temperatures exceeding 1500 degrees Celsius without significant degradation. The longevity and durability of the refractories depend on this capability. Secondly, the refractories must have good thermal shock resistance. Since soaking pits often experience rapid changes in temperature, the refractories must be able to handle these fluctuations without cracking or spalling. This is vital to maintain the refractories' integrity. Chemical attacks are another concern in soaking pit applications. Molten metal, slag, and other corrosive substances are present, so the refractories must have excellent chemical resistance. This prevents erosion and chemical reactions. Withstanding the corrosive effects of molten metal and slag, as well as potential chemical reactions, is crucial. Furthermore, mechanical stresses, such as abrasion and impact, occur in soaking pits due to the movement and handling of metal ingots. The monolithic refractories should possess good mechanical strength and abrasion resistance to withstand these stresses. They should be able to resist wear and tear caused by heavy loads and avoid any mechanical failure. Lastly, the refractories used in soaking pits should be easy to work with and install. This ensures efficient and effective lining of the pit, minimizing any gaps or cracks that could lead to heat loss or chemical penetration. In summary, monolithic refractories for soaking pit applications must meet specific requirements regarding high temperature resistance, thermal shock resistance, chemical resistance, mechanical strength, and ease of installation. Fulfilling these requirements guarantees that the refractories can withstand the harsh conditions of soaking pits and maintain their performance and integrity over an extended period.

Send your message to us

Monolithic Refractories Zirconia Slide Gate Nozzle Upper and Lower Nozzle Brick for Iron and Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords