Monolithic Refractories Zirconia Slide Gate Nozzle for Iron and Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

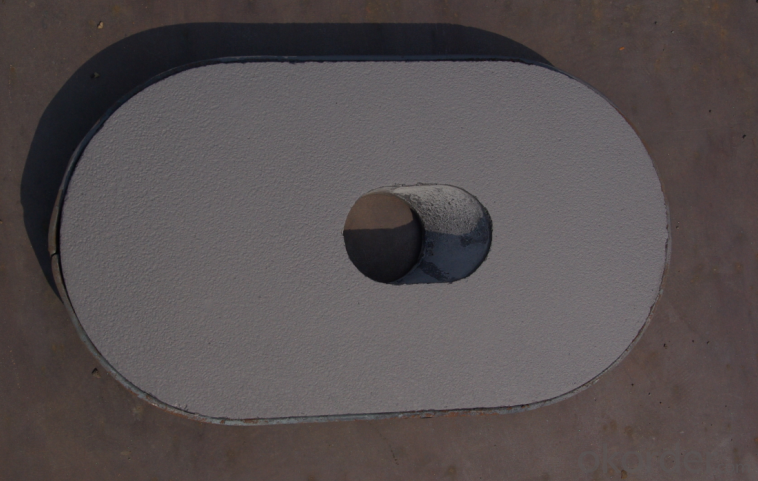

Zirconia Slide Gate Nozzle for Steel Industry

Slide gate plate widely used in large ladle, middle ladle and small ladle to fit for high quality steel casting.

Slide gate plate widely including Alumina carbon and Alumina Zirconia Carbon slide gate plate, MgO and MgO-spinel slide gate plate,nonoxides bonding slide gate plateand unburned slide gate plate.

Burnt Slide gate

Item B60,B50,C40type | Al-C Slide Gate | Al-Zr-C Slide Gate | ||||||

AlC-70 | AlC -75 | AlC -80 | AlC-85 | AlC -86 | AlZrC -70 | AlZrC-75 | AlZrC -77 | |

Al2O3,% | 70 | 75 | 80 | 85 | 86 | 70 | 75 | 77 |

C+SiC,% | 7 | 7 | 5 | 5 | 4 | 7 | 7 | 7 |

ZrO2,% | - | - | - | - | - | 6 | 6 | 2.5 |

A.P.,% max | 10 | 10 | 10 | 10 | 7 | 10 | 10 | 10 |

B.D.,g/cm3 | 2.8 | 2.9 | 2.9 | 3.0 | 2.95 | 3.00 | 3.05 | 2.90 |

C.C.S., MPa min | 65 | 70 | 100 | 100 | 100 | 110 | 115 | 100 |

Unburned compound AlC Slide gate

Item B60,B50,C40type | Al-C Slide Gate | ||||

AlC-70A | AlC-75A | AlC-80A | AlC-85A | AlC-86A | |

Al2O3,% | 70 | 75 | 80 | 85 | 86 |

C,% | 7 | 7 | 5 | 5 | 4 |

A.P.,% max | 10 | 10 | 8 | 10 | 7 |

B.D. g/cm3 min | 2.8 | 2.9 | 3.0 | 3.0 | 2.95 |

C.C.S., MPa min | 65 | 70 | 100 | 100 | 100 |

zirconium core :

Item | ZN- 65 | ZN- 70 | ZN- 75 | ZN- 80 | ZN- 85 | ZN- 90 | ZN- 93A | ZN- 93B | ZN- 93C | ZN- 93D | ZN- 95A | ZN- 95B | ZN- 96 |

ZrO2(%) | ≥65 | ≥70 | ≥75 | ≥80 | ≥85 | ≥90 | ≥93 | ≥93 | ≥93 | ≥93 | ≥95 | ≥95 | ≥96 |

Bulk density (g/cm3) | ≥3.8 | ≥3.8 | ≥3.9 | ≥4.0 | ≥4.1 | ≥4.3 | ≥5.1 | ≥4.9 | ≥4.7 | ≥4.4 | ≥4.6 | ≥5.2 | ≥5.2 |

Apparent Porosity(%) | ≤23 | ≤22 | ≤22 | ≤20 | ≤20 | ≤20 | ≤13 | ≤15 | ≤18 | ≤20 | ≤20 | ≤9 | ≤5.6 |

Thermal shock resistance (cycles)(1100℃,water cooling) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >8 | >10 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do monolithic refractories impact the quality of iron and steel products?

- Monolithic refractories play a crucial role in enhancing the quality of iron and steel products. These refractories are used to line the furnaces, ladles, and other equipment involved in the production process. By providing excellent thermal insulation and resistance to high temperatures, monolithic refractories help maintain stable and controlled heating conditions, which is essential for achieving desired chemical compositions and microstructures in iron and steel. Moreover, these refractories minimize heat loss, prevent contamination, and reduce the formation of impurities, thus ensuring the production of high-quality and defect-free iron and steel products.

- Q: What are the common manufacturing processes used for monolithic refractories?

- The common manufacturing processes used for monolithic refractories include mixing the raw materials, shaping the mixture into the desired form, and then curing or firing it at high temperatures to achieve the desired strength and properties. Some specific processes used are casting, gunning, ramming, and spraying.

- Q: What are the different techniques for installing monolithic refractories?

- There are several techniques for installing monolithic refractories, each with its own advantages and suitability for different applications. Some of the common techniques include: 1. Casting: In this technique, the refractory material is mixed with water or a binder to form a slurry. The slurry is then poured into molds or directly onto the prepared surface. The material is allowed to set and harden, forming a solid monolithic structure. 2. Gunning: Gunning involves spraying the refractory material onto the surface using a gunning machine. The material is mixed with water or a binder to form a wet mix, which is then propelled onto the surface at high velocity. This technique is commonly used for repairing or lining larger areas and can be done onsite. 3. Ramming: Ramming involves compacting the refractory material into place using a pneumatic or manual ramming tool. The material is typically preheated to reduce moisture content and increase workability. This technique is often used for lining smaller areas or for filling gaps between bricks or precast shapes. 4. Shotcreting: Shotcreting is a technique similar to gunning, but it involves using a dry mix of refractory material. The dry mix is combined with water or a binder just before it is sprayed onto the surface using a high-pressure nozzle. Shotcreting is commonly used for lining larger areas or for creating complex shapes. 5. Troweling: Troweling involves applying the refractory material onto the surface using a trowel or a similar tool. The material is typically a wet mix and is spread and smoothed manually. This technique is often used for patching or repairing small areas or for finishing touches. 6. Vibrating: Vibrating involves using a vibrating tool or a vibrator to compact the refractory material and remove air pockets. This technique is commonly used for improving the density and strength of the monolithic refractory after it has been installed using other techniques. It is important to note that the selection of the technique depends on various factors such as the type of refractory material, the size and shape of the area to be lined, and the specific requirements of the application. Additionally, proper preparation of the surface and adherence to installation guidelines are crucial for ensuring the effectiveness and longevity of the monolithic refractory.

- Q: Can monolithic refractories be used in electric arc furnaces and induction furnaces?

- Yes, monolithic refractories can be used in both electric arc furnaces and induction furnaces. Monolithic refractories are versatile and can withstand the high temperatures and thermal shocks generated in these types of furnaces. They are often preferred due to their ease of installation, improved energy efficiency, and suitability for various furnace lining applications.

- Q: What are the key properties of ramming mixes used for monolithic refractory installations?

- The key properties of ramming mixes used for monolithic refractory installations include high density, good flowability, high strength, excellent thermal shock resistance, chemical resistance, and low porosity. These properties ensure the ramming mix can be compacted easily during installation, withstand high temperatures without cracking, and resist chemical attacks from molten metals or corrosive gases. Additionally, low porosity helps to minimize heat loss and enhance the overall performance and longevity of the refractory lining.

- Q: How are monolithic refractories used in the iron and steel industry?

- Due to their exceptional performance and versatility, monolithic refractories are widely utilized in various applications within the iron and steel industry. Composed of a uniform material, these refractories serve as seamless linings in high-temperature environments. In the iron and steel industry, the significance of monolithic refractories cannot be overstated as they play a crucial role in multiple stages of the manufacturing process. A primary application is seen in the blast furnace, where the inside of the furnace is lined with monolithic refractories. This lining is exposed to exceedingly high temperatures and harsh chemical reactions. By providing excellent thermal insulation and resistance to chemical attack, monolithic refractories ensure the durability and longevity of the blast furnace. Another crucial application is witnessed in the steelmaking process, where monolithic refractories are used to line the ladles and tundish, utilized for transporting and pouring molten steel. These refractories are specially designed to withstand the corrosive nature and high temperatures of the molten steel, thus preventing contamination and guaranteeing the quality of the final product. Furthermore, monolithic refractories find application in various ancillary equipment and structures within the iron and steel industry. They are employed in furnaces, kilns, and other heat treatment systems to provide insulation and maintain high-temperature conditions. Additionally, they are used in the construction of chimneys, exhaust ducts, and other exhaust systems, where they offer thermal insulation and resistance against corrosive gases. Overall, the vital role played by monolithic refractories in the iron and steel industry lies in their ability to provide high-temperature insulation, chemical resistance, and durability. They optimize the production process, enhance energy efficiency, and ensure the quality of the final product. With their exceptional performance and versatility, monolithic refractories have become an indispensable component within the iron and steel manufacturing industry.

- Q: How do monolithic refractories withstand mechanical stress in the iron and steel industry?

- Monolithic refractories are designed to endure mechanical stress in the iron and steel industry due to their distinctive composition and properties. Unlike traditional brick-like refractories, which consist of multiple pieces, these refractories have a single, uniform structure. This monolithic structure offers several advantages in terms of mechanical stress resistance. To begin with, monolithic refractories possess greater strength and density compared to traditional refractories. This enables them to withstand the mechanical forces exerted during various processes in the iron and steel industry, such as the movement of molten metal, the impact of scrap materials, or the pressure from gases and liquids. Their superior strength and density help prevent cracking, deformation, or failure under these stressful conditions. Moreover, monolithic refractories provide excellent resistance to thermal shock, which is crucial in the iron and steel industry. The rapid heating and cooling cycles experienced in processes like steelmaking or iron casting can subject refractories to thermal stress. However, the monolithic structure of these refractories allows for better thermal conductivity and expansion, reducing the risk of thermal shock damage. This ability to withstand thermal stress contributes to their overall resistance to mechanical stress. Furthermore, monolithic refractories can be customized and applied on-site, resulting in a seamless lining that eliminates joints or weak spots. This seamless application ensures a more uniform distribution of stress and prevents the formation of cracks or gaps that could weaken the refractory lining. By eliminating these vulnerabilities, monolithic refractories enhance their ability to resist mechanical stress in the demanding conditions of the iron and steel industry. In conclusion, monolithic refractories endure mechanical stress in the iron and steel industry due to their high strength and density, superior resistance to thermal shock, and seamless application. These properties enable them to withstand the intense mechanical forces encountered during various processes, ensuring the durability and efficiency of refractory linings in this demanding industry.

- Q: What are the cost implications of using monolithic refractories in the iron and steel industry?

- The use of monolithic refractories in the iron and steel industry can have various cost implications. Firstly, the initial cost of monolithic refractories tends to be higher compared to traditional brick refractories. Monolithic refractories are typically made from high-quality raw materials and require specialized installation techniques, leading to higher upfront expenses. However, these higher upfront costs can be offset by the benefits provided by monolithic refractories in terms of performance, durability, and reduced maintenance requirements. One of the major cost implications of using monolithic refractories is their extended service life. Monolithic refractories have excellent thermal shock resistance and can withstand high temperatures, mechanical stress, and corrosive environments. This results in reduced downtime and fewer replacement or repair needs, leading to overall cost savings in the long run. Additionally, monolithic refractories offer flexibility in design and application. They can be easily shaped and installed to fit complex geometries, resulting in optimized furnace linings and improved energy efficiency. By minimizing heat loss, monolithic refractories can reduce fuel consumption and lower energy costs for the iron and steel industry. Furthermore, the installation and maintenance of monolithic refractories can be less labor-intensive compared to brick refractories. This can result in reduced labor costs and shorter installation time, leading to potential cost savings for the industry. Another cost implication of using monolithic refractories is their impact on productivity. Monolithic refractories provide improved thermal insulation, reduced slag adhesion, and enhanced resistance to wear and erosion. These properties can lead to increased production rates, improved product quality, and minimized process interruptions, ultimately translating into higher profitability for iron and steel manufacturers. It is important to note that the cost implications of using monolithic refractories can vary depending on the specific application, furnace type, and operating conditions. Therefore, a thorough cost-benefit analysis should be conducted to evaluate the overall economic impact of implementing monolithic refractories in the iron and steel industry.

- Q: How do monolithic refractories help in improving the quality of iron and steel products?

- Several ways exist in which monolithic refractories play a crucial role in enhancing the quality of iron and steel products. Firstly, these refractories are utilized for lining furnaces and other high-temperature equipment in the iron and steel industry. By offering excellent thermal insulation, monolithic refractories aid in maintaining a consistent and controlled temperature inside the furnace, thus ensuring efficient heating and melting of metals. Furthermore, the utilization of monolithic refractories aids in reducing heat loss, thereby enhancing the energy efficiency of the process. This not only leads to cost savings but also minimizes the environmental impact associated with high energy consumption. Additionally, the insulation properties of monolithic refractories contribute to the reduction of thermal stresses within the furnace, preventing cracks and other structural damages that could potentially affect the quality of the iron and steel products. Moreover, monolithic refractories possess exceptional resistance to chemical reactions, corrosion, and erosion caused by molten metals, slag, and other harsh substances. This resistance helps in maintaining the integrity of the refractory lining, preventing the contamination of iron and steel products by unwanted impurities. As a result, the quality of the final products, such as steel bars, sheets, or pipes, is enhanced, meeting the desired specifications and industry standards. Another advantage offered by monolithic refractories is their ability to provide a sleek and pristine lining surface. This smoothness minimizes the adherence of slag, molten metal, and other by-products, thereby reducing the risk of defects and ensuring a higher-quality finish for the iron and steel products. Additionally, the clean lining surface facilitates easy maintenance and cleaning, enabling efficient and effective operations. In conclusion, monolithic refractories significantly contribute to the improvement of iron and steel product quality through their exceptional thermal insulation, resistance to chemical reactions, erosion, and corrosion, as well as their ability to provide a sleek and pristine lining surface. By ensuring consistent temperatures, reducing heat loss, preventing structural damages, and maintaining a clean environment, monolithic refractories enhance the overall efficiency and integrity of the iron and steel production process, resulting in high-quality end products.

- Q: How do monolithic refractories improve the efficiency of ladle and tundish lining systems?

- The efficiency of ladle and tundish lining systems is greatly enhanced by monolithic refractories in several ways. Firstly, these refractories are made from a single piece of material, eliminating the need for joints or seams. This seamless construction guarantees a lack of weak points in the lining system, reducing the chances of molten metal leakage or infiltration. Moreover, monolithic refractories possess exceptional thermal insulation properties. With their low thermal conductivity, they are able to withstand high temperatures without transferring heat to the surrounding environment. This insulation capability minimizes heat loss from the ladle or tundish, resulting in improved heat retention and energy efficiency. Additionally, it ensures that the desired temperature of the molten metal is maintained, preventing premature solidification and ensuring the necessary fluidity for casting. Furthermore, monolithic refractories exhibit outstanding resistance to chemical attacks caused by molten metal and slag. Their excellent corrosion resistance properties ensure the durability and integrity of the lining, even in the face of aggressive chemical reactions. This resistance to corrosion prolongs the lifespan of the lining system, reducing the need for frequent maintenance and replacement, thereby increasing overall efficiency and reducing downtime. Another advantage of monolithic refractories is their easy installation. Unlike traditional brick or block linings, monolithic refractories can be applied as a single, uniform layer, simplifying and speeding up the installation process. This reduces the time required for lining repairs or replacements, minimizing disruptions to production and enhancing the overall operational efficiency of ladles and tundishes. In conclusion, monolithic refractories enhance the efficiency of ladle and tundish lining systems through their seamless construction, excellent thermal insulation, superior corrosion resistance, and easy installation. These characteristics ensure improved heat retention, reduced heat loss, increased durability, and minimized downtime, resulting in enhanced productivity and cost-effectiveness for metal casting processes.

Send your message to us

Monolithic Refractories Zirconia Slide Gate Nozzle for Iron and Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords