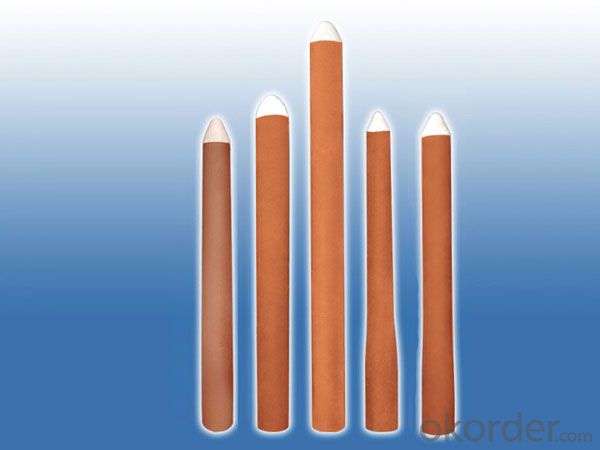

Monoblock Stopper for continuous casting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

1.excellent thermal shock resistance;

2.excellent mechanical properties and resistance to vibration

3. long service life

Monoblock stopper is one of the important steel flow regulation components, and to meet the particularly demanding operating conditions, we manufacture varieties of stoppers with customised specifications to suit the different designs of our customers' tundishes

To facilitate customisation, during our manufacturing process, we apply different mixtures of aluminia or magnesia to the nose of our stoppers for our customers, enabling them to cast various types of steel.

The characteristics of the stopper are as follows:

PARMETER | Major portion | Stopper head | Stopper head | Stopper head |

F.C+SiC (%) | 20 | 10 | 20 | 12 |

Al2O3 (%) | 68 | 80 | ||

ZrO2 (%) | 72 | |||

MgO (%) | 75 | |||

apparent porosity(%) | 15 | 14 | 16 | 15 |

bulk density(g/cm3) | 2.35 | 2.80 | 3.30 | 2.70 |

CCS (Mpa) | 27 | 26 | 27 | 25 |

MOR (Mpa) | 8.0 | 8.0 | 9.0 | 8.0 |

The stopper head is the key part. Standard materials are:

Alumina carbon suitable for ordinary steel flow control

Zirconium carbon suitable for special alloy steel flow control

Magnesia carbon suitable for Ca-treatment steel flow control

- Q: How are monolithic refractories recycled or disposed of at the end of their lifespan?

- Monolithic refractories, widely utilized in high-temperature industrial applications, offer various means of recycling or disposal once their lifespan concludes. The preferred approach depends on the specific monolithic refractory type and its composition. Reclamation stands as a common method for recycling monolithic refractories. This process entails collecting used refractory materials and subjecting them to processing to eliminate any impurities or contaminants. The resultant reclaimed refractory material can then be crushed, ground, or milled into a fine powder suitable for utilization as a raw material in manufacturing new refractories. Thermal treatment represents an alternative means of recycling monolithic refractories. This method involves exposing the used refractory material to high temperatures within a controlled environment, such as a kiln or furnace. The heat effectively breaks down the refractory material, eliminating any binders or impurities. The resulting material can then be reused as a raw material or integrated into other applications, such as construction aggregates. When recycling is not feasible, specialized facilities designed for handling and treating hazardous waste offer a disposal avenue for monolithic refractories. These facilities ensure the proper containment and treatment of the refractory material, minimizing any potential environmental impact. This disposal method is typically reserved for refractories containing hazardous substances or those that cannot be recycled due to their composition. It is important to emphasize that the appropriate disposal or recycling method for monolithic refractories must adhere to local regulations and guidelines. These regulations aim to ensure the safe handling, treatment, and disposal of these materials, taking into account their potential environmental and health effects. Therefore, industries and businesses must collaborate closely with waste management professionals and adhere to the appropriate procedures to responsibly manage monolithic refractories at the end of their lifespan.

- Q: How do monolithic refractories contribute to the reduction of heat loss in iron and steel furnaces?

- Monolithic refractories play a crucial role in reducing heat loss in iron and steel furnaces. These refractories are designed to provide a continuous lining throughout the furnace, eliminating joints and seams that can result in thermal leaks. One way monolithic refractories contribute to heat loss reduction is through their excellent thermal insulation properties. They have low thermal conductivity, meaning they are effective at restricting the transfer of heat from the furnace to its surroundings. This insulation helps to maintain the high temperatures required for efficient iron and steel production within the furnace, while minimizing heat loss to the surrounding environment. Another way monolithic refractories contribute to heat loss reduction is by providing a protective barrier that prevents the escape of hot gases and molten metal. This barrier helps to maintain the integrity of the furnace lining, preventing any gaps or cracks that could allow heat to escape. By ensuring a tight and continuous lining, monolithic refractories reduce heat loss by keeping the heat contained within the furnace. Furthermore, monolithic refractories have high resistance to thermal shock and erosion, which are common challenges in iron and steel furnaces. These refractories can withstand rapid temperature changes, preventing any sudden cracks or failures that could lead to heat loss. Additionally, they are resistant to the corrosive effects of molten metal and hot gases, ensuring the longevity of the lining and maintaining its insulating properties over time. In summary, monolithic refractories contribute to the reduction of heat loss in iron and steel furnaces through their excellent thermal insulation properties, ability to provide a continuous lining, resistance to thermal shock and erosion, and protection against corrosive substances. By minimizing heat loss, these refractories optimize the energy efficiency and productivity of the furnace, ultimately leading to cost savings and improved overall performance in the iron and steel industry.

- Q: How do monolithic refractories prevent heat loss through convection?

- Monolithic refractories effectively prevent heat loss through convection due to their unique composition and structure. Unlike traditional refractory bricks, which often have gaps and are porous, monolithic refractories are made of a single, seamless structure. This eliminates any possible pathways for hot gases or air to circulate and carry away heat by convection. Furthermore, monolithic refractories have a high thermal conductivity and are often dense, making them excellent conductors of heat. This allows them to rapidly absorb and distribute heat, minimizing the temperature difference between the hot surface and the surrounding environment. By reducing the temperature gradient, monolithic refractories decrease the driving force for convection, resulting in reduced heat loss through this mechanism. Moreover, monolithic refractories can be applied as a continuous lining, conforming to the shape of the equipment or furnace being protected. This seamless application eliminates joints or gaps where hot gases or air could escape and carry away heat. The uniform and uninterrupted lining further decreases the potential for convection heat loss. In summary, monolithic refractories are specifically designed to create a barrier that hinders the movement of hot gases or air, effectively minimizing heat loss through convection. Their dense composition, high thermal conductivity, and seamless application all contribute to their effectiveness in preventing heat loss through this mechanism.

- Q: How do monolithic refractories enhance the performance of ladle and tundish preheating systems?

- Monolithic refractories enhance the performance of ladle and tundish preheating systems by providing excellent thermal insulation, high mechanical strength, and resistance to corrosion and erosion. This allows for efficient heat retention and distribution, ensuring uniform and consistent preheating of ladles and tundishes. Additionally, monolithic refractories minimize heat losses, reduce energy consumption, and increase the lifespan of the preheating systems, contributing to improved overall performance.

- Q: What are the cost implications of using monolithic refractories in the iron and steel industry?

- The use of monolithic refractories in the iron and steel industry can have various cost implications. Firstly, the initial cost of monolithic refractories tends to be higher compared to traditional brick refractories. Monolithic refractories are typically made from high-quality raw materials and require specialized installation techniques, leading to higher upfront expenses. However, these higher upfront costs can be offset by the benefits provided by monolithic refractories in terms of performance, durability, and reduced maintenance requirements. One of the major cost implications of using monolithic refractories is their extended service life. Monolithic refractories have excellent thermal shock resistance and can withstand high temperatures, mechanical stress, and corrosive environments. This results in reduced downtime and fewer replacement or repair needs, leading to overall cost savings in the long run. Additionally, monolithic refractories offer flexibility in design and application. They can be easily shaped and installed to fit complex geometries, resulting in optimized furnace linings and improved energy efficiency. By minimizing heat loss, monolithic refractories can reduce fuel consumption and lower energy costs for the iron and steel industry. Furthermore, the installation and maintenance of monolithic refractories can be less labor-intensive compared to brick refractories. This can result in reduced labor costs and shorter installation time, leading to potential cost savings for the industry. Another cost implication of using monolithic refractories is their impact on productivity. Monolithic refractories provide improved thermal insulation, reduced slag adhesion, and enhanced resistance to wear and erosion. These properties can lead to increased production rates, improved product quality, and minimized process interruptions, ultimately translating into higher profitability for iron and steel manufacturers. It is important to note that the cost implications of using monolithic refractories can vary depending on the specific application, furnace type, and operating conditions. Therefore, a thorough cost-benefit analysis should be conducted to evaluate the overall economic impact of implementing monolithic refractories in the iron and steel industry.

- Q: What are the key factors affecting the installation and curing of monolithic refractories?

- There are several key factors that can affect the installation and curing of monolithic refractories. These factors include the selection of the appropriate refractory material, proper surface preparation, correct mixing and application techniques, controlled drying and curing process, and adherence to manufacturer's guidelines and recommendations. Additionally, factors such as temperature, humidity, and atmospheric conditions can also impact the installation and curing of monolithic refractories.

- Q: What are the main factors affecting the erosion resistance of monolithic refractories?

- Several key factors influence the erosion resistance of monolithic refractories. These factors encompass the chemical composition of the refractory material, the microstructure of the material, the temperature and environment in which it is utilized, and the mechanical properties of the material. The erosion resistance of monolithic refractories heavily relies on the chemical composition. The inclusion of specific chemical elements and compounds can enhance the refractory's resistance to erosion, while others may render it more susceptible. For instance, the addition of alumina (Al2O3) to the refractory composition can augment its erosion resistance by forming a protective layer on the surface. Conversely, the presence of impurities or excessive amounts of certain elements can weaken the refractory and heighten its susceptibility to erosion. The microstructure of the monolithic refractory is another critical factor affecting erosion resistance. The microstructure denotes the arrangement and distribution of particles within the refractory. A well-structured microstructure with a uniform particle distribution can provide superior erosion resistance as it ensures an even distribution of load when exposed to erosive forces. Conversely, a poorly structured microstructure with particle clusters or weak bonding may result in localized erosion and failure. Erosion resistance is significantly influenced by the temperature and environment in which the refractory is employed. High temperatures can induce thermal stresses, chemical reactions, and phase changes in the refractory material, all of which impact its erosion resistance. Additionally, the presence of corrosive gases, liquids, or slags can expedite erosion by promoting chemical reactions or attacking the refractory material, leading to its deterioration. Lastly, the mechanical properties of the monolithic refractory, including strength, hardness, and toughness, contribute to erosion resistance. A refractory with higher mechanical strength and hardness can withstand erosive forces more effectively than a weaker material. Similarly, increased toughness aids in the refractory's resistance to cracking or spalling when subjected to impact or thermal shock, reducing its vulnerability to erosion. To summarize, the erosion resistance of monolithic refractories is influenced by the chemical composition, microstructure, temperature and environment, and mechanical properties of the material. Understanding and optimizing these factors can facilitate the development of refractories with enhanced erosion resistance for diverse industrial applications.

- Q: How do monolithic refractories improve the performance of ladles and tundishes?

- The performance of ladles and tundishes is significantly improved by monolithic refractories in various ways. Firstly, these vessels are thermally insulated by monolithic refractories, which act as a barrier against heat loss and help maintain the desired temperature. This insulation reduces energy consumption and minimizes heat loss. Secondly, monolithic refractories offer excellent resistance to chemical corrosion and erosion. When ladles and tundishes come into contact with molten metal and fluxes, they can be severely corroded and eroded. However, the use of monolithic refractories protects against chemical attacks and extends the lifespan of these vessels. This saves costs associated with frequent repairs or replacements and ensures their integrity and safety. Furthermore, monolithic refractories provide superior mechanical strength and structural stability. Ladles and tundishes must withstand the weight of molten metal and the stresses caused during pouring and handling. With high mechanical strength, monolithic refractories can withstand these loads, maintaining their shape and integrity. This reduces downtime and increases productivity in the steelmaking process. Moreover, monolithic refractories offer flexibility in design and installation. They can be shaped and applied in various configurations, allowing customization to meet the specific requirements of ladles and tundishes. This flexibility ensures a better fit and improves the overall efficiency of the refractories, ultimately enhancing the performance of the vessels. In conclusion, monolithic refractories enhance the performance of ladles and tundishes by providing improved thermal insulation, resistance to chemical corrosion and erosion, increased mechanical strength, and flexibility in design and installation. These benefits contribute to the longevity, efficiency, and cost-effectiveness of ladles and tundishes in steelmaking operations.

- Q: How do monolithic refractories improve energy efficiency in the iron and steel industry?

- Monolithic refractories play a crucial role in improving energy efficiency in the iron and steel industry through various mechanisms. Firstly, these refractories have excellent insulation properties, which help in reducing heat loss during the production process. By minimizing heat loss, monolithic refractories ensure that more heat is retained within the furnace, resulting in higher energy efficiency. Moreover, monolithic refractories have low thermal conductivity, allowing for better heat transfer within the furnace. This means that the heat generated during the production process can be efficiently distributed throughout the furnace, enabling optimal temperature control and reducing energy wastage. In addition, monolithic refractories have high resistance to thermal shock and corrosion, which are common challenges in the iron and steel industry. By withstanding extreme temperatures and chemical reactions, these refractories prevent premature wear and tear, thus reducing the need for frequent repairs and replacements. This not only saves energy but also minimizes downtime, leading to increased productivity and energy efficiency. Furthermore, the use of monolithic refractories allows for better furnace design and optimization. Their flexibility enables the creation of custom shapes and linings that suit specific furnace requirements, resulting in improved heat transfer and combustion efficiency. This customized approach promotes energy savings by maximizing the utilization of fuel and reducing emissions. Lastly, monolithic refractories have a longer lifespan compared to traditional brick refractories. This prolonged durability reduces the frequency of refractory replacements, resulting in lower energy consumption associated with the manufacturing and installation of new refractories. Overall, monolithic refractories contribute significantly to energy efficiency in the iron and steel industry by reducing heat loss, improving heat transfer, withstanding thermal shock and corrosion, enabling better furnace design, and increasing refractory lifespan. Their use not only saves energy but also enhances productivity and sustainability within the industry.

- Q: How do monolithic refractories improve the efficiency of ladle and tundish drying furnaces?

- Monolithic refractories improve the efficiency of ladle and tundish drying furnaces by providing excellent thermal insulation, high resistance to thermal shock, and superior strength. These properties ensure minimal heat loss during the drying process, allowing for faster and more efficient heating. Additionally, monolithic refractories offer better resistance to erosion and corrosion, prolonging the lifespan of the furnaces and reducing maintenance requirements. Overall, the use of monolithic refractories enhances the performance and productivity of ladle and tundish drying furnaces.

Send your message to us

Monoblock Stopper for continuous casting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords