Monolithic Refractories for Iron and Steel Industry - Fireclay Based Mortar for Hot Blast Stove

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Fireclay Based Mortar for Hot Blast Stove

Made as per international standards, FIREF fireclay based mortar for hot blast stove is known for its low thermal conductivity, high refractoriness, and excellent thermal shock resistance.

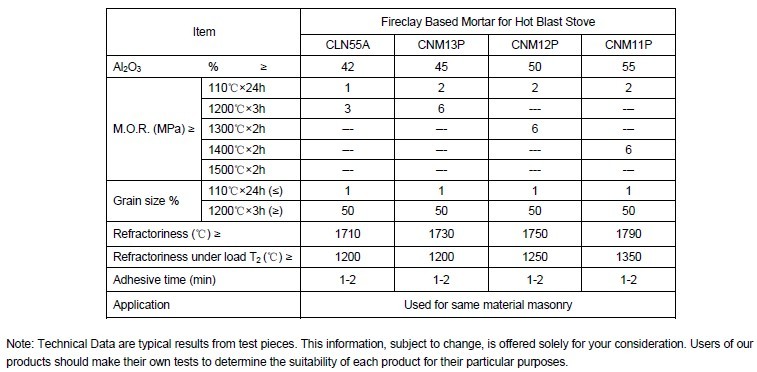

Technical data of Fireclay Based Mortar for Hot Blast Stove

Production line and packing of Fireclay Based Mortar for Hot Blast Stove

Feature of Fireclay Based Mortar for Hot Blast Stove

Low thermal conductivity

High refractoriness

Excellent thermal shock resistance

Excellent mechanical strength

Application of Fireclay Based Mortar for Hot Blast Stove

FIREF fireclay based mortar for hot blast stove can be used together with the same material fireclay bricks.

Production Flow of Fireclay Based Mortar for Hot Blast Stove

- Q: How do monolithic refractories contribute to the overall efficiency of iron and steel production?

- Monolithic refractories play a crucial role in enhancing the overall efficiency of iron and steel production. These refractories, which are made from a single material, provide exceptional thermal insulation, resistance to high temperatures, and excellent mechanical strength. By lining the furnaces, ladles, and other equipment used in the production process, monolithic refractories help in maintaining and regulating the required high temperatures for melting, refining, and shaping iron and steel. This insulation reduces heat loss, minimizes energy consumption, and ensures a more efficient and cost-effective production process. Additionally, the mechanical strength of monolithic refractories allows for better protection against wear and tear, resulting in increased equipment lifespan and reduced downtime for repairs and maintenance. Overall, the use of monolithic refractories significantly contributes to the efficiency, productivity, and sustainability of the iron and steel production industry.

- Q: How do monolithic refractories perform in ladle lining applications in the iron and steel industry?

- Monolithic refractories are highly effective in ladle lining applications in the iron and steel industry. Their outstanding thermal shock resistance, erosion resistance, and high refractoriness allow them to withstand the extreme conditions of molten metal and slag in ladles. Monolithic refractories also offer excellent thermal conductivity and low porosity, ensuring efficient heat transfer and preventing slag infiltration. Additionally, their easy installation and maintenance make them a preferred choice for ladle lining, ensuring prolonged service life and enhanced productivity in the iron and steel industry.

- Q: How are monolithic refractories used in the repair and maintenance of ladle and tundish linings?

- Monolithic refractories are used in the repair and maintenance of ladle and tundish linings by providing a durable and heat-resistant material that can withstand the harsh conditions of molten metal handling. These refractories are applied as a single, continuous lining, eliminating the need for individual bricks or tiles, which simplifies the repair and maintenance process. They can be easily shaped and installed in the desired areas, allowing for efficient repair of damaged sections. Monolithic refractories also offer excellent resistance to thermal shock, erosion, and corrosion, ensuring the longevity and reliability of ladle and tundish linings.

- Q: Can monolithic refractories be used for the lining of continuous casting tundishes and molds?

- Yes, monolithic refractories can be used for the lining of continuous casting tundishes and molds. Monolithic refractories are versatile and can be shaped or molded to fit the specific requirements of the tundish and mold lining. They offer excellent thermal shock resistance and high-temperature stability, making them suitable for the harsh conditions of continuous casting. Additionally, monolithic refractories have low porosity, which helps prevent the penetration of molten metal and promotes longer service life for the tundish and mold lining.

- Q: What are the typical applications of monolithic refractories in the iron and steel industry?

- Monolithic refractories are widely used in various applications within the iron and steel industry. These refractories, which are made of a single material, offer several advantages such as ease of installation, resistance to thermal shock, and excellent resistance to chemical attacks. Here are some typical applications of monolithic refractories in the iron and steel industry: 1. Blast Furnace: Monolithic refractories are used in the lining of blast furnaces, where they are subjected to extreme temperatures and chemical reactions. They provide thermal insulation, prevent erosion, and resist the corrosive effects of molten iron and slag. 2. Ladles and Tundishes: Monolithic refractories are used to line ladles and tundishes, which are vessels used for transporting and transferring molten metal. These refractories offer good thermal insulation and resistance to erosion and chemical attack, ensuring the integrity of the vessels. 3. Steelmaking Converters: Monolithic refractories are utilized in converters, which are used in the steelmaking process to convert molten pig iron into steel. These refractories provide protection against the high temperatures and aggressive chemical environments encountered during the process. 4. Electric Arc Furnaces (EAF): Monolithic refractories are used to line the walls and roofs of EAFs, which are used to melt scrap steel for recycling. These refractories offer excellent thermal insulation, resistance to slag erosion, and thermal shock resistance, ensuring the longevity and efficiency of the furnace. 5. Continuous Casting: Monolithic refractories are employed in the continuous casting process, where molten steel is solidified into a continuous slab or billet. These refractories line the walls and floors of the casting molds, providing thermal insulation and resistance to chemical attack from the molten steel. 6. Reheating Furnaces: Monolithic refractories are used in reheating furnaces, which are used to heat steel billets or ingots prior to further processing. These refractories provide insulation, resist high temperatures, and ensure uniform heating of the metal. Overall, monolithic refractories play a crucial role in the iron and steel industry by providing reliable and durable linings in various applications. Their ability to withstand extreme temperatures, chemical attacks, and thermal shocks makes them indispensable for maintaining the integrity and efficiency of the production processes.

- Q: How do monolithic refractories enhance the efficiency of reheating furnaces?

- Monolithic refractories play a crucial role in enhancing the efficiency of reheating furnaces in several ways. Firstly, monolithic refractories offer excellent thermal insulation properties, which minimize heat losses from the furnace. This insulation helps to maintain a high and consistent temperature inside the furnace, reducing the need for excessive fuel consumption and improving energy efficiency. Secondly, monolithic refractories have high thermal conductivity, which allows for efficient heat transfer within the furnace. This means that the heat generated by the burners can be evenly distributed throughout the furnace, ensuring uniform heating of the materials being reheated. This uniform heating not only enhances the overall efficiency but also helps to prevent hot spots or cold spots, which can negatively impact the quality of the reheated products. Moreover, monolithic refractories have excellent resistance to thermal shock and mechanical stress. Reheating furnaces often undergo rapid temperature changes and are subjected to intense mechanical forces due to the movement of materials and the operation of various equipment. The use of monolithic refractories helps to prevent cracks, spalling, and other forms of refractory damage, thus ensuring the longevity and continuous operation of the furnace without interruptions for repairs. Additionally, monolithic refractories offer ease of installation, repair, and maintenance compared to traditional brick refractories. Their ability to be cast or sprayed onto the furnace lining allows for a more precise and seamless installation, reducing the risk of weak joints or gaps that could compromise the furnace's efficiency. Furthermore, in case of any damage or wear, monolithic refractories can be easily repaired or patched up, minimizing downtime and improving the overall productivity of the furnace. In summary, the use of monolithic refractories in reheating furnaces enhances efficiency by providing effective thermal insulation, facilitating uniform heat distribution, resisting thermal shock and mechanical stress, and allowing for easier installation and maintenance. These benefits contribute to lower energy consumption, improved product quality, increased furnace durability, and reduced operational costs.

- Q: What are the factors affecting the thermal expansion of monolithic refractories?

- The factors affecting the thermal expansion of monolithic refractories are the composition of the refractory material, the temperature gradient, and the firing or curing process.

- Q: How do monolithic refractories enhance the performance of ladle and tundish covers?

- Monolithic refractories enhance the performance of ladle and tundish covers by providing high thermal conductivity, excellent resistance to thermal shock, and superior mechanical strength. These properties ensure efficient heat insulation, minimize heat loss, and prevent cracking or damage due to rapid temperature changes. Additionally, monolithic refractories offer good corrosion resistance, prolonging the lifespan of the ladle and tundish covers and improving their overall performance.

- Q: How do monolithic refractories withstand chemical attack from molten metals and slag?

- Monolithic refractories withstand chemical attack from molten metals and slag due to their unique composition and properties. These refractories are made of a single, homogeneous material, which provides them with better resistance against chemical corrosion. Additionally, monolithic refractories are designed to have low porosity and high density, which limits the penetration of molten metals and slag into their structure. These materials also have high melting points, enabling them to withstand the extreme temperatures present in industrial processes. Overall, the combination of their composition, low porosity, high density, and high melting points makes monolithic refractories highly resistant to chemical attack from molten metals and slag.

- Q: How do monolithic refractories contribute to the safety of iron and steel plants?

- Monolithic refractories play a crucial role in ensuring the safety of iron and steel plants. These refractories are specially designed to withstand high temperatures, chemical attacks, and mechanical stresses commonly encountered in these industrial settings. By utilizing monolithic refractories, iron and steel plants can benefit in the following ways: 1. Thermal resistance: Monolithic refractories have excellent resistance to extreme temperatures, preventing heat loss and ensuring the efficient operation of various equipment and systems. This thermal insulation contributes to the safety of the plant by reducing the risk of overheating, which could lead to equipment failure or even catastrophic accidents. 2. Chemical resistance: Iron and steel plants involve the use of various chemicals, including molten metal, slag, and corrosive gases. Monolithic refractories exhibit high resistance to these aggressive chemical environments, preventing corrosion, erosion, and material degradation. This resistance ensures the integrity of refractory linings, reducing the risk of leaks, spills, and contamination that could jeopardize the safety of workers and the environment. 3. Structural stability: Monolithic refractories provide excellent mechanical strength, offering structural stability to the linings of furnaces, ladles, and other equipment. This stability is crucial for the safe operation of iron and steel plants, as it minimizes the risk of structural failure, collapse, or damage caused by mechanical stresses or heavy loads. 4. Rapid repair and maintenance: Monolithic refractories offer the advantage of easy installation and repair compared to traditional brick refractories. Their application involves pouring, gunning, or ramming the refractory material in place, which allows for quick repairs and maintenance. This rapid response to refractory failures or damages contributes to the plant's safety by minimizing downtime and preventing potential hazards associated with equipment malfunction. 5. Flexibility and adaptability: Monolithic refractories can be tailored to meet the specific needs and requirements of iron and steel plants. They can be customized in terms of composition, density, thermal conductivity, and other properties, allowing for optimal performance under varying operating conditions. This adaptability ensures that refractory linings are well-suited for the plant's processes, reducing the likelihood of accidents or incidents caused by inadequate refractory materials. In summary, monolithic refractories enhance the safety of iron and steel plants by providing thermal resistance, chemical resistance, structural stability, rapid repair capabilities, and flexibility. By utilizing these refractories, iron and steel plants can maintain a safe working environment, minimize the risk of accidents, and ensure the reliable operation of their equipment and systems.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Monolithic Refractories for Iron and Steel Industry - Fireclay Based Mortar for Hot Blast Stove

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords