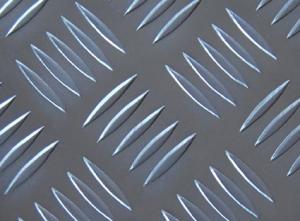

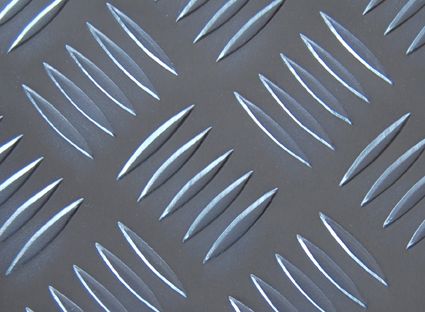

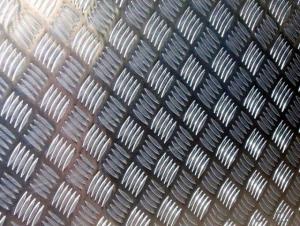

Foam Core Aluminum Sheets - 3003 3004 5052 5754 Five Bar/Diamond Aluminum Checker Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum checkered sheet / plate 3003

1. Alloy: 3003

2. Temper: O-H112

3.Ridge Length: 38mm; Ridge height:0.8-1.2mm

4.Thickness: 1.0-6.0mm

5.Width: 500-2300mm

6.Length: 500-10000mm

7.Main application:

1)Transport vehicles

2)Industrial sheds

3)Fabrication industry

Chamical Components of 3003

Manganese (Mn) | Silicon (Si) Max | Copper (Cu) Max | Iron (Fe) | Zinc (Zn) | Aluminum (Al) |

1-1.5 | 0.6 | 0.2 | 0.7 | 0.15-0.35 | Remainder |

Mechanical Pproperties

Tensile Strength (PSI) | Yield Strength (PSI) | Elongation in 2" |

22,000 | 21,000 | 10 |

Packaging & Delivery

| Packaging Details: | 20-30 days |

| Delivery Detail: | Export standard, covering with plastic film, packed with wood |

FAQ:

Q1.Are you factory or trading company?

A1.We are factory with export rights.

Q2.How many workers in your company?

A2.Around 100-150.

Q3.How long have you been in this product?

A3:More than 10 years.

Q4.What’s your main markets?

A4. Southeast Asia, Mid East, South America ,Africa, Eastern Europe

Q5.What's the minium quantity(MOQ)?

A5.2 Metric tons

Q6.How long is shipping time?

A6.Depending on your quantity normally 15-30 days..

Q7.How do you guarantee the quality?

A7.Professional workers and advanced equipment, all according to the quality standard and client request. QC will check the quality before packaging.

Q8.Do you have after sale service?

A8.Yes.Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: This question asks for methods to verify the quality of aluminum sheets before purchasing them.

- <p>To ensure the quality of aluminum sheets, first, check for certifications such as ISO or ASTM standards. Inspect the surface for any defects like scratches, dents, or unevenness. The color should be uniform and the edges should be smooth. Request a sample and perform a bend test to check for flexibility and strength. Ensure the thickness is consistent as specified. Look for a reputable supplier with good customer reviews. Lastly, consider the price; if it's too low, it might indicate compromised quality.</p>

- Q: Can aluminum plates be welded with stainless steel or iron nuts?

- If the thickness of the sheet is not enough, the effective thread stroke can be mounted with K nuts. Rivet nuts are required if accuracy is required.If it is a thick aluminum sheet, it can be directly drilled and tapped; also, the steel screw sleeve can be added.

- Q: Hi everyone, I have this problem that I'm somewhat confused about. The problem is:An alloy of aluminum and magensium was treated with sodium hydroxide solution, in which only aluminum reacts to give hydrogen gas:2Al + 2NaOH + 6H20 --gt; 2NaAl(OH)4 + 3H2If a sample of alloy weighing 1.118 g gave 0.1068 g of hydrogen, what is the percentage aluminum in the alloy?How do I account for the magnesium and what stoichiometric relationships would I need to set-up? This is very confusing, but I appreciate the slightest of help on this!Thank you.

- You don't need to worry about the magnesium at all, because it doesn't enter into the reaction. You have a balanced equation for aluminium and hydrogen, and the data given are sufficient: From the equation, you know that 2 moles of aluminium produce 3 moles of H2. 0.1068 g of H2 were produced, so divide this by molecular mass of H2 (2.016) to determine the moles of H2 produced. You know that 3 moles of H2 would have been produced from 2 moles of Al. Therefore, multiply the moles of H2 by 2/3, to determine the moles of Al that were present. Now multiply this number by the atomic mass of Al, to determine the grams of Al. Now divide this number if grams by 1.118 and multiply by 100 to determine % Al present in the alloy.

- Q: Is aluminum a metal or a non-metal?

- Aluminum, a metal, holds the chemical element designation Al along with atomic number 13. Its categorization as a metal stems from its distinctive physical and chemical traits. The characteristics of aluminum include its display of a metallic luster, its ability to conduct heat and electricity, and its possession of considerable tensile strength. Moreover, aluminum is known for its malleability and ductility, enabling it to be effortlessly shaped into various forms. Furthermore, aluminum is typically observed in a solid state when subjected to room temperature, a trait commonly associated with metals. Consequently, aluminum is deemed a metal based on its properties and its placement within the periodic table.

- Q: What are the standard sizes of aluminum sheets?

- The standard sizes of aluminum sheets vary, but some common dimensions include 4 feet by 8 feet, 4 feet by 10 feet, and 5 feet by 10 feet.

- Q: How do you join two aluminum sheets together?

- There are several methods to join two aluminum sheets together. One common technique is using mechanical fasteners such as screws, rivets, or bolts. These fasteners can be drilled or punched through the sheets, creating a secure connection. Another method is using adhesives specifically designed for aluminum bonding. These adhesives provide a strong and durable bond between the two sheets. Welding is another popular option, where the aluminum sheets are melted and fused together using heat. This method requires specialized equipment and expertise. Lastly, a technique called clinching can be used, which involves applying pressure to deform the aluminum sheets and interlock them together. Each method has its own advantages and considerations, depending on the specific application and desired outcome.

- Q: A solid aluminum sphere has a mass of 83 g.Use the density of aluminum to find the radius of the sphere in inchesExpress your answer using two significant figures.I can't figure this out :(

- Aluminum's density is about 2.7 grams per cubic centimeter. So a sphere with a mass of 84grams has a volume of about 31.111 cubic centimeters. You get this by dividing 84 by 2.7. Now that you know the volume, you can calculate the radius of the sphere. for a sphere, volume = 4/3 pi * radius to the third power. So 31.111 = 4/3 * (3.14...) * r^3. Divide both sides by 4/3 then divide both sides by pi and you get something like r^3 is 7.427. Then find the cube root of this to find your radius. I don't have a calculator, so someone should check the numbers.

- Q: What rules or guidelines exist for using recycled aluminum sheets in construction projects?

- <p>Yes, there are regulations and guidelines regarding the use of recycled aluminum sheets in construction. These often include standards for material quality, safety, and environmental impact. The American Society for Testing and Materials (ASTM) and the Aluminum Association provide specifications for recycled aluminum alloys used in construction. Compliance with building codes and local regulations is essential. Additionally, recycled aluminum must meet performance and safety standards equivalent to those of new materials. It's crucial to check with local building authorities and consult the latest industry standards to ensure compliance when using recycled aluminum in construction.</p>

- Q: How do aluminum sheets compare to steel sheets in terms of strength?

- Aluminum sheets and steel sheets differ in terms of strength. Steel is generally stronger than aluminum, as it has a higher tensile strength, meaning it can withstand greater forces without breaking or deforming. Steel sheets are commonly used in applications that require high strength and durability, such as construction, automotive manufacturing, and aerospace. On the other hand, aluminum sheets offer a good balance between strength and weight. While aluminum is not as strong as steel, it is significantly lighter, which makes it advantageous in certain applications where weight reduction is a priority, such as the manufacturing of aircraft and vehicles. Additionally, aluminum sheets have excellent corrosion resistance, making them suitable for outdoor or marine environments. Ultimately, the choice between aluminum and steel sheets depends on the specific requirements of the application, considering factors like strength, weight, durability, and corrosion resistance.

- Q: what kind of aluminum sheet is suitable for aluminum alloy double-edged saw?

- saw web size depends on the thickness and height of sectional material,equipment compatibility and permitted installed saw web size .

Send your message to us

Foam Core Aluminum Sheets - 3003 3004 5052 5754 Five Bar/Diamond Aluminum Checker Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords