Mill Finished Aluminum Tin Sheets 3003 Alloy for Color Coating China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finished Aluminum Coil 3003 Alloy for Color Coating China Supply

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC |

TEMPER | H14,H18,H24,H26,H32 |

THICKNESS | 0.2MM-20MM |

WIDTH | 10mm-1500mm |

COIL WGT | 2Mt - 3Mt |

Coil ID | 20" |

SURFACE | Mill finished etc |

STANDARD | GB/T 3880-2006 |

2. Application of Mill Finished Aluminum Coil 3003 Alloy for Color Coating China Supply

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finished Aluminum Coil 3003 Alloy for Color Coating China Supply

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

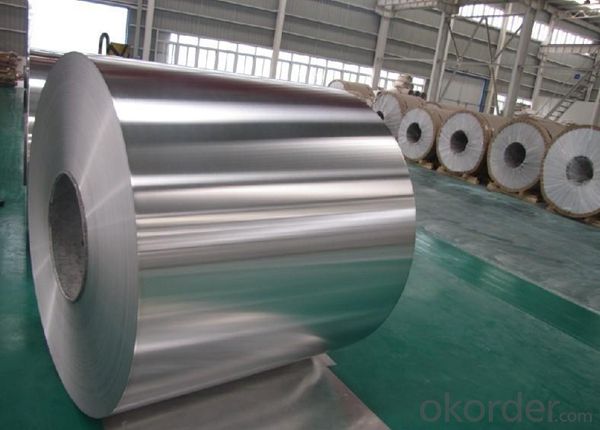

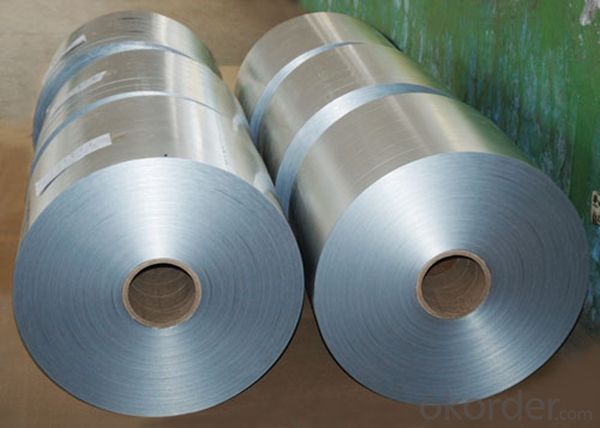

5. Image of Mill Finished Aluminum Coil 3003 Alloy for Color Coating China Supply

6. Package and shipping of Mill Finished Aluminum Coil 3003 Alloy for Color Coating China Supply

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum sheets be anodized for corrosion protection?

- Yes, aluminum sheets can be anodized for corrosion protection. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This oxide layer is highly resistant to corrosion and provides a durable and long-lasting protection. Anodizing can be done on various aluminum products, including sheets, to enhance their corrosion resistance, improve their appearance, and increase their lifespan. The process involves immersing the aluminum sheet in an electrolyte solution and applying an electric current, which causes oxygen ions to bond with the surface of the metal, forming the protective oxide layer. Anodized aluminum sheets are widely used in industries such as aerospace, automotive, construction, and electronics, where corrosion resistance is crucial.

- Q: Are 101 aluminum sheets resistant to corrosion?

- Indeed, 101 aluminum sheets display remarkable resistance to corrosion. This is attributed to aluminum's inherent ability to form an oxide layer on its surface upon exposure to oxygen, which serves as a formidable shield against corrosion and safeguards the metal from deterioration. Furthermore, the 101 aluminum alloy is meticulously engineered with superior properties that bolster its resistance to corrosion, surpassing other aluminum alloys in this regard. Consequently, when confronted with the need for corrosion resistance, 101 aluminum sheets stand as a dependable option.

- Q: Are aluminum sheets suitable for food-grade applications?

- Yes, aluminum sheets are suitable for food-grade applications. Aluminum is a non-toxic and non-reactive metal, making it safe for direct contact with food. It is also lightweight, durable, and resistant to corrosion, making it an ideal choice for various food-related uses such as packaging, cooking utensils, and food processing equipment.

- Q: Can aluminum sheet be used for solar panels?

- Yes, aluminum sheets can be used for solar panels. They are commonly used as the backing material or frame for solar panels due to their lightweight, corrosion-resistant, and durable properties.

- Q: Can aluminum sheets handle high temperatures?

- Certainly! High temperatures are well-tolerated by aluminum sheets. With a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum proves itself suitable for various applications requiring elevated temperatures. Furthermore, aluminum possesses exceptional thermal conductivity, enabling rapid heat dissipation. This attribute renders aluminum sheets ideal for deployment in environments necessitating resistance against high temperatures, including engine components, heat exchangers, and oven linings. Nevertheless, it is crucial to take into account the specific alloy and thickness of the aluminum sheet, as different alloys may impose different temperature thresholds.

- Q: Are aluminum sheets resistant to abrasion?

- Yes, aluminum sheets are generally resistant to abrasion due to their hardness and durability.

- Q: I have some carbon arrows for my bow but I was wondering if aluminum arrows penetrate farther into a deer because they weigh more. I read somewhere that they do but I just wanted to confirm that.

- Depends on what you're planning on doing with them really. But definitely no on the fiberglass. Long distance shots (50m), definitely carbon. Certain carbons do last longer, I shoot Carbon Express Nano XR, built like a tank, no aluminum comes close to the durability. Before this, I've shot ACE, built for speed and breaks left and right. So, moral of the story is, carbon's durability depends on make and model. Sadly, I have to disagree with DumDum this time around about the carbon's rigidity. For a given shaft weight, the carbon shaft will bend less than aluminums. However, for a given bow/archer setup, you need carbon shafts that bends as much as aluminum for that same setup. The basis of bow tuning is this requirement that the arrow need to bend a certain amount during the shot. Take away the bending and the arrow won't fly straight, hence the archer's paradox. Given a well tuned setup, the only variables to penetration is the KE, and the surface friction as the arrow enters the target.

- Q: is steel better for making bicycle frames.....how does it differ from the aluminum framed bikes?

- It depends on the type of riding you do. If you ride long distance you don't want aluminum, it is very stiff and will wear out your body with jolts from the road. Steel provides some degree of flex, which softens road jolts. You might want to go to a bike shop and hold a steel bike and alum bike so you can appreciate the difference in weight. Another thing about alum bikes is they do suffer from metal fatigue, so they will not last for 20 years like a steel bike (perhaps even much less depending on usage).

- Q: I saw some pretty horrific pictures today of bow shooters with their hands impale by pieces of a carbon arrow that broke after being shot. I'm about to get into the archery sport, and I just want to know before I buy my arrows, will it be safer to buy aluminum shaft arrows instead of carbon? People said aluminum ones aren't as strong, but right now I'm more concern with the safety factor. Yes, I do know that I'm suppose to always check carbon arrows for cracks before I shoot them, but we're all human and sometimes people will forget and make mistakes. I just don't want my hand embedded with carbon shrapnel. So should I get carbon or aluminum? Maybe the new full metal jacket ones will be a good compromise?As a side note, my first bow will be a recurve somewhere around the 30-35 lb draw range. Does the power of the bow affect the chances of an arrow breakage?

- Your 30-35 lb draw bow is slightly underpowered for hunting. Some states regulate the draw weight to around 50 lbs. So that your arrow does damage when it hits. I would recommend a compound bow as they are easier to draw and the power is there. tTe power will affect the arrow as they bend pretty good when released. But all arrows do that.even the glass and wooden arrows. If there is a flaw in the arrow throw it away!!

- Q: How do I calculate the weight of aluminum sheet? What is the density?

- First calculate the density of each aluminum plate, then calculate the volume, then the density is good, the volume is the weight

Send your message to us

Mill Finished Aluminum Tin Sheets 3003 Alloy for Color Coating China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords