Nordic Ware Mill Finished Aluminum Sheet for Subway Cabin

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished Aluminium Sheet for Subway Cabin Description

Mill Finished Aluminium Sheet for Subway Cabin is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished Aluminium Sheet for Subway Cabinle

Mill Finished Aluminium Sheet for Subway Cabin | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished Aluminium Sheet for Subway Cabin

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished Aluminium Sheet for Subway Cabin

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished Aluminium Sheet for Subway Cabin

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

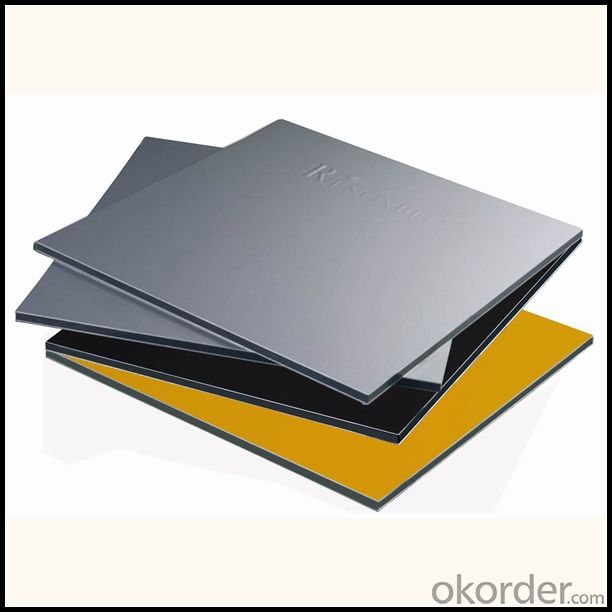

6. Image of Mill Finished Aluminium Sheet for Subway Cabin

7. Package and shipping of Mill Finished Aluminium Sheet for Subway Cabin

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the different types of alloys used for painted aluminum sheets?

- There are various types of alloys used for painted aluminum sheets, including the commonly used 3003 and 5052 alloys. These alloys offer excellent corrosion resistance and formability, making them suitable for a wide range of applications. Additionally, other alloys such as 6061 and 7075 are utilized for their high strength properties in more demanding or specialized applications.

- Q: Can aluminum sheets be anodized for aesthetic purposes?

- Yes, aluminum sheets can be anodized for aesthetic purposes. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This layer can be dyed in various colors, creating a wide range of aesthetic options. Anodized aluminum sheets are popular in architectural applications, such as building facades, as they provide a durable and visually appealing finish. The anodized layer also enhances the corrosion resistance and wear resistance of the aluminum, making it suitable for both indoor and outdoor uses. Additionally, anodized aluminum sheets can be further processed through techniques like etching or laser engraving, allowing for the creation of intricate designs and patterns.

- Q: Can aluminum sheet be used for electrical enclosures?

- Yes, aluminum sheet can be used for electrical enclosures. Aluminum is a commonly used material in the electrical industry due to its excellent conductivity, corrosion resistance, and lightweight properties. It provides good shielding against electromagnetic interference and is easy to fabricate into various shapes and sizes for enclosures.

- Q: This question asks for a comparison of aluminum sheets with other materials regarding their cost and performance.

- <p>Aluminum sheets are generally cost-effective and offer excellent performance compared to many other materials. They are lightweight, which reduces material and transportation costs. They also have high strength-to-weight ratios, making them durable and resistant to corrosion. In terms of performance, aluminum sheets are versatile, used in various industries such as construction, automotive, and aerospace. They conduct heat and electricity well, which is beneficial for applications requiring thermal or electrical conductivity. However, they may be more expensive than some plastics or cheaper metals like steel on a per-unit basis, but their lower weight and durability often offset this cost over time.</p>

- Q: I'm thinking of starting raised beds for a vegetable garden. I'm thinking about a shallow aluminum stock tank, about 12 in. deep x 4 ft. long. Having limited sunlight available, these could be moved around the yard and tended to easily. Any ideas? Aluminum with soil? Any effects? Holes will be drilled in the bottom for drainage. Thanks!

- They work great !

- Q: Do 101 aluminum sheets require any special maintenance or care?

- Maintenance or care is not necessary for 101 aluminum sheets. This material is durable and resistant to corrosion, allowing it to endure different environmental conditions without degradation. Nevertheless, to guarantee their longevity and optimal performance, it is suggested to regularly wipe them with a soft cloth or sponge to keep them free of dirt or debris. It is also advisable to avoid using abrasive or harsh cleaning agents in order to prevent potential harm to the aluminum sheets. In summary, with minimal attention and care, 101 aluminum sheets can retain their quality and appearance for an extended duration.

- Q: Calculate the mass in grams of Iodine (I2) that will react completely with 20.4 g of aluminum to form aluminum oxide (AlL3)

- Aluminium oxide? Shouldn't it be Aluminium iodide? 1. Form a balanced equation 3I2 + 4Al - 2Al2I3 2. Number of moles of Al 20.4/(Mr of Al) = 20.4/27 = 0.7555mol 3. Number of moles of I2 0.7555/4 x 3 = 0.5666mol 4. Mass of I2 required = 0.5666 x Mr of I2 = 0.5666 x (127x2) Ans: 143.9164g

- Q: Are 101 aluminum sheets suitable for agricultural machinery?

- Yes, 101 aluminum sheets are suitable for agricultural machinery.

- Q: Can aluminum sheet be used for automotive applications?

- Yes, aluminum sheet can be used for automotive applications. Aluminum is a lightweight and strong material that offers several advantages in the automotive industry. It is widely used in the production of car bodies, hoods, doors, and other structural components. Aluminum sheets are preferred for these applications because they provide excellent strength-to-weight ratio, corrosion resistance, and durability. Additionally, aluminum is easily formable, which allows for complex shapes and designs to be achieved. The use of aluminum in automotive applications also helps to improve fuel efficiency and reduce emissions due to its lighter weight. Overall, aluminum sheet is a suitable choice for automotive applications due to its numerous beneficial properties.

- Q: How much do aluminum sheets typically weigh?

- The weight of aluminum sheets can vary depending on their thickness and dimensions. However, on average, aluminum sheets typically weigh between 2.7 to 3.0 grams per square centimeter.

Send your message to us

Nordic Ware Mill Finished Aluminum Sheet for Subway Cabin

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords