Mill Finish Five Bar Aluminum Chequer Plate - Aluminum Trailer Siding Sheets Ontario

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Five Bar Aluminum Chequer Plate

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Mill Finish Five Bar Aluminum Chequer Plate

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Five Bar Aluminum Chequer Plate

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

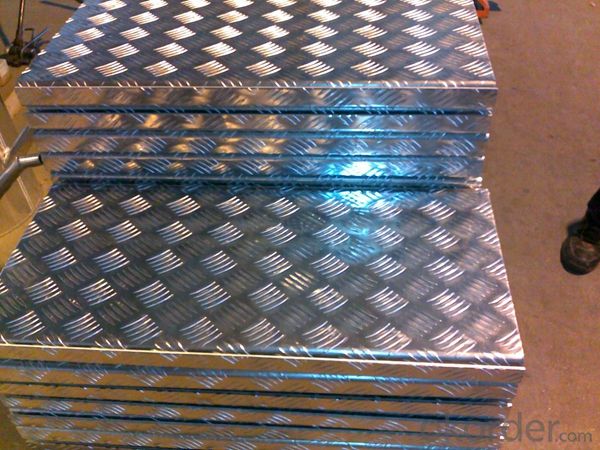

5. Image of Mill Finish Five Bar Aluminum Chequer Plate

6. Package and shipping of Mill Finish Five Bar Aluminum Chequer Plate

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How does the surface roughness affect the friction properties of aluminum sheet?

- The friction properties of an aluminum sheet are significantly affected by its surface roughness. When the surface is rough, there are more microscopic peaks and valleys, which can enhance the frictional forces between the sheet and the contacting surfaces. Generally, an increase in surface roughness results in a higher friction coefficient. This occurs because the roughness increases the effective contact area between the aluminum sheet and the opposing surface, leading to more interlocking and adhesion between the two surfaces. Consequently, the resistance to relative motion, or friction, is heightened. Moreover, a rough surface can trap lubricants or contaminants, reducing lubrication efficiency and increasing friction. The roughness of the aluminum sheet also influences the formation and retention of a lubricating film, further impacting the friction properties. It is important to acknowledge that the type of roughness, such as its amplitude, wavelength, and orientation, can also affect the friction properties. For instance, certain surface textures, like grooves or patterns, may facilitate lubricant retention and reduce friction, even with increased roughness. In summary, the friction properties of an aluminum sheet are significantly determined by its surface roughness. A rough surface increases the contact area and adhesion between the sheet and opposing surface, resulting in higher friction coefficients. However, the specific characteristics of the roughness and the presence of lubricants or contaminants can further influence the friction behavior.

- Q: Are aluminum sheets prone to warping?

- Yes, aluminum sheets are prone to warping, especially when exposed to high temperatures or subjected to excessive pressure. However, the extent of warping depends on various factors such as the thickness of the sheet, the specific alloy used, and the conditions it is exposed to.

- Q: What is an aluminum sheet?

- An aluminum sheet refers to a flat, thin piece of aluminum that is usually rectangular in shape. It is commonly used in various industries and applications due to its lightweight, durability, and corrosion resistance properties. Aluminum sheets can be easily manipulated, cut, and formed into different shapes to meet specific requirements in construction, automotive, aerospace, and manufacturing sectors.

- Q: What are the dimensions and thickness options for aluminum sheets?

- The dimensions and thickness options for aluminum sheets vary depending on the specific requirements and applications. Aluminum sheets are available in a wide range of sizes and thicknesses to suit different needs. In terms of dimensions, aluminum sheets can be found in various widths and lengths, typically ranging from 36 inches to 72 inches in width and 96 inches to 144 inches in length. These dimensions can, however, vary depending on the supplier and specific product. The thickness options for aluminum sheets also vary. The thickness is typically measured in gauge, with lower gauge numbers indicating thicker sheets. Aluminum sheets are available in various gauges, ranging from 0.006 inches (very thin) to 0.5 inches (thicker) or even thicker for specialized applications. It's important to note that specific dimensions and thickness options may vary depending on the supplier and the specific grade of aluminum being used. It is always recommended to consult with a supplier or manufacturer for precise information on available dimensions and thickness options for aluminum sheets.

- Q: why can't aluminum sheet burn after polishing?

- because aluminum will rapidly formulate dense oxide film once being exposed in air, oxide film will generate after polishing, it can't burn.

- Q: What are the different thickness tolerances for aluminum sheets?

- The thickness tolerances of aluminum sheets can vary based on the grade and application. Normally, the standard tolerances range from +/- 0.006 inches to +/- 0.015 inches. However, it is important to recognize that these tolerances can be stricter or more lenient depending on the specific requirements of the end-use application. For example, in precision-focused industries like aerospace or automotive, tighter tolerances of +/- 0.003 inches might be necessary. Conversely, for less critical applications, looser tolerances of +/- 0.020 inches may be acceptable. To determine the suitable thickness tolerances for a particular aluminum sheet, it is always advisable to consult industry standards or manufacturers' specifications.

- Q: What's the price of the 6mm aluminum sheet?

- The single aluminum plate is aluminum substrate, around the hem (can be customized size and shape) and install bracket forming a mounting edge, the surface of the fluorocarbon coating (various colors can be customized). Aluminum single board, white meters, Beijing reference price of 320 yuan / square meter, specific to take into account your size, material requirements, plate type and so on, generally see drawings quote.

- Q: Can aluminum sheets be used for food display cases?

- Yes, aluminum sheets can be used for food display cases. Aluminum is a popular choice for food display cases due to its exceptional strength, durability, and resistance to corrosion. Additionally, aluminum is lightweight, making it easier to handle and transport the display cases. Its clean, sleek appearance also enhances the presentation of the food items, making it an ideal material for showcasing various food products. Moreover, aluminum is non-toxic and does not react with food, ensuring the safety and hygiene of the displayed items. Overall, aluminum sheets are a suitable and practical choice for constructing food display cases.

- Q: have been taking an over the counter Antacid consistently for the past 8 years as a daily source of extra calcium per the bottle. Now, I am getting many nerve problems, similar to Lou Gehrig's disease. I am a healthy 38 year old male who excersises, eats right and is generally health conscious. I am concerned that unknowingly I have toxified my body with the aluminum that apparently is in Antacid. I did not know this until now or of course I would not have gone any where near it.Can taking Antacid lead to nerve problems such as Lou Gehrig's disease?

- Aluminum okorder /

- Q: Can the aluminum sheets be used for manufacturing decorative trim?

- Yes, aluminum sheets can be used for manufacturing decorative trim. Aluminum is a versatile material that is lightweight, durable, and resistant to corrosion. It can be easily shaped and formed into various decorative designs and patterns. Additionally, aluminum can be coated or painted in different colors to enhance its aesthetic appeal. Therefore, aluminum sheets are a popular choice for manufacturing decorative trim in various industries, including architecture, automotive, and interior design.

Send your message to us

Mill Finish Five Bar Aluminum Chequer Plate - Aluminum Trailer Siding Sheets Ontario

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords