Englert Aluminum Coil - Mill Finish Aluminum Coil for Metal Roofing 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

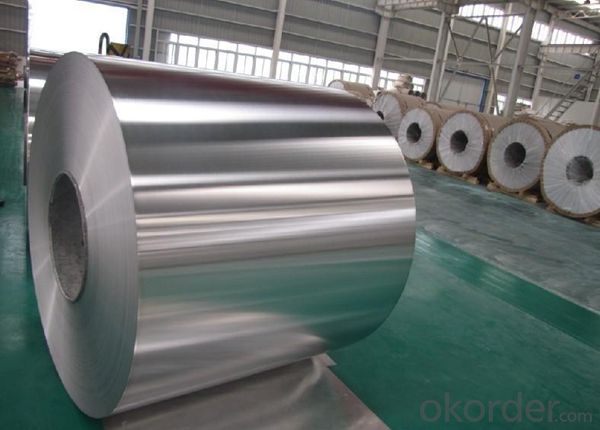

Mill Finish Aluminum Coil for Metal Roofing 1XXX 3XXX 5XXX

1.Structure of Mill Finish Aluminum Coil for Metal Roofing 1XXX 3XXX 5XXX

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Mill Finish Aluminum Coil for Metal Roofing 1XXX 3XXX 5XXX

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

3. Mill Finish Aluminum Coil for Metal Roofing 1XXX 3XXX 5XXX Images

4.Specification of Mill Finish Aluminum Coil for Metal Roofing 1XXX 3XXX 5XXX

Alloy Number | AA5XXX 1XXX 3XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ of Mill Finish Aluminum Coil for Metal Roofing 1XXX 3XXX 5XXX

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: What are the common sizes of aluminum coils?

- The common sizes of aluminum coils can vary depending on the specific industry and application. However, some commonly used sizes include widths ranging from 36 inches to 72 inches, with thicknesses typically ranging from 0.019 inches to 0.125 inches.

- Q: which metal is very common today and which one will be most common in future. steel or aluminum

- Steel is definitely most common engineering material. Aluminum is lighter and is finding increasing use in transport industry due to energy cost and global warming. It is unlikely that it will surpass steel ever in future due to higher cost. Magnesium has the potential of growing to beat both of these metals (magnesium is more abundant on earth than either aluminum or iron (steel).

- Q: What is the thickness range of aluminum coils?

- The thickness of aluminum coils can differ depending on the particular application and industry. Generally, aluminum coils range from 0.006 to 0.25 inches (0.15 to 6.35 mm) in thickness. This wide range enables diverse uses, ranging from delicate and lightweight applications like packaging materials or electrical components to thicker coils utilized in construction or automotive sectors. It should be emphasized that these are broad ranges, and the desired thickness may vary depending on the specific use and customer requirements.

- Q: How to purchase PE polyester coated aluminum sheet and PVDF fluorocarbon coated aluminum coil?

- Both belong to color coated aluminum sheet and coil. Customers can purchase ordinary aluminum sheet or coil, and then go to special coating company to add PE polyester coating or PVDF fluorocarbon coating. The color is bright and quality is also very good. PE polyester coated aluminum and PVDF fluorocarbon coated aluminum coil has a wide range of usages: construction industry (aluminum-plastic panel, aluminum honeycomb, roof corrugated sheet, fireproof veneer, aluminum ceiling, shutter, rolling shutter door, garage door, awning, water gutter), electronic appliances (computer chassis, computer panel), lighting, furniture, solar reflector, air conditioning duct and the like. At present it is still applied in many areas including electronic appliance, instrument, lighting, packaging and house decoration.

- Q: Why do the layers loose when taking out coil after roll of aluminum 0.14?

- After rolling, the most possible reason may be poor deoiling effect. I think, for 0.14mm aluminum coil, the lining sleeve will not be forgotten. After rolling , oil ooze from aluminum layers, and the support of aluminum coil is not enough, leading to coil collapsing. The specific manifestations are that the edges of even round aluminum layers become like water ripple, and that the aluminum coils suddenly become uneven when taking out coil.

- Q: A piece of aluminum foil 0.550 mm thick and 1.00 cm square is allowed to react with bromine to form aluminum bromide?a) How many mole of aluminum were used? ( The density of aluminum is 2.699 g/cm3.)I keep getting the same answer which I know is wrong. I used a formula to get the volume and then the mass to get the moles, but maybe this is wrong. Could someone explain the process. I got 4.32 x 10-1 mol Al, but the answer is 5.50 x 10-3 mol Al.

- volume= 0.0550 cm x 1.00 cm^2= 0.0550 cm^3 gms Al= 2.699 g/cc x [vol] 0.0550 cc = 0.148 g moles Al = [grams]/[mole wt] mol wt=26.98 so 2.699[g/cc] x 0.0550[cc] / 26.98 =0.00550 or 5.50x 10^-3 to 3 sig fig units cancel and gram-moles is final unit.

- Q: Is it possible to use an electric stove with an aluminum coil heater?

- <p>Yes, you can use an electric stove with an aluminum coil heater. However, it's important to ensure that the aluminum coil heater is designed for use with an electric stove. Aluminum is a good conductor of heat and can be used in heating elements. Make sure the heater is compatible with the stove's power requirements and that it's installed correctly to avoid any safety hazards. Always follow the manufacturer's instructions for installation and use.</p>

- Q: An aluminum bar 3.80 m long has a rectangular cross section 1.00 cm by 5.00 cm, what is the resistance and what is the length of a copper wire 1.50 mm in diameter having the same resistance?

- Resistance Of Aluminum

- Q: This question asks about the distinctions among various grades of aluminum coils, likely referring to their properties and uses.

- <p>Aluminum coils are differentiated by grades based on their alloy composition, thickness, and specific applications. Common grades include 1000 series (99% pure aluminum, soft and malleable), 3000 series (aluminum-manganese alloys, good for cooking utensils), 5000 series (aluminum-magnesium alloys, used in marine applications), and 6000 series (aluminum-magnesium-silicate alloys, known for strength and used in construction). Each grade has distinct properties such as strength, formability, and corrosion resistance, which determine their suitability for different industries and applications.</p>

- Q: A cube of solid aluminum has a volume of 1.00 m3 at 20°C. What temperature change is required to produce a 130 cm3 increase in the volume of the cube?

- The linear expansivity of aluminum is 23 x10^-6 /K. Bulk expansivity is 3 x 23 x10^-6 / k For 130 [cm^3] the temperature required is 130 [cm] ^3/ 3 x 23 x10^-6 = 0.00013/[3 x 23 x10^-6] = 1.88 K ========================= If each side of the cube of side 1m expands by e, then its new volume = [1+e]^3 = 1 + 3e + 3e^2 +e^3. Neglecting high powers of e as negligible, the increase in volume is 3e. But e = 23 x10^-6 x rise in temperature 3e = 3*23 x10^-6 x rise in temperature. Given 3e = 0.00013 0.00013= 3*23 x10^-6 x rise in temperature Rise in temperature = 0.00013 / 3*23 x10^-6 = 1.88 K

Send your message to us

Englert Aluminum Coil - Mill Finish Aluminum Coil for Metal Roofing 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords