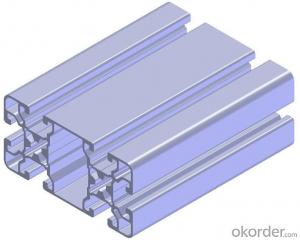

Mill Aluminum Extrusion Profiles Products

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Management Certification: ISO 9001:2008

Temper: O,F, H112,T4,T5,T6 and T8

Hardness: according to the alloy status

Specifications

1Aluminum alloy tube :AA3003/MOD/3005MOD/4343/7072/4104 etc

2,Temper: H14/24 etc.

3,For Radiator/Inter/oilcoolerEvaporator etc

1. Aluminum tube material for intercooler:

AA3003/3003+Zn/3003MOD/3004/3005/3005MOD/7072/4343/+zn/4045/+zn/4104/4004,etc

Per customer special requirement

Core alloy & Clad Alloy

3. Thickness Range:0.8mm≤T≤1.7MM (per customer special req.)

4.Width Range:10mm≤W≤1380mm

Product/Service (We Sell): | Aluminum coil, Aluminum foil, Aluminum plate non-cladded or cladded alloy) for

|

6. Packaging:

Per customer special requirement

Mark brazing side/non-braze side, water side

Clockwise /anticlockwise, eye to sky/eye to horizon

Cutting with paper core/aluminum core/steel core

Seaworthy Wooden Pallet standard; aluminum coils

- Q: Aluminum blackening formula

- Blackening is a common method used in metal heat treatment. The principle is to produce a layer of oxide film on the surface of metal so as to isolate the air and achieve the purpose of anti rust. The appearance of requirements is not high by blackening a blackening process, mainly by the following steps: 1) 2): degreasing cleaning; the workpiece must be completely immersed in the degreasing solution; degreasing solution concentration pH value 12-14, processing time 10-30min, every 3-5 minutes on shake a few times, the concentration of less than pH12 when adding defatted powder; washing; 3) 4): pickling pickling liquid concentration pH value 2-4, the processing time of 5-10min; 5) washing; 6): black pool concentration pH value 2.5-3.5, the processing time of 10-12min; 7) washing; 8) dry; 9) oil. The beneficial effects of the invention are as follows: 1., the blackening is safe, the electricity is not required; the alkaline blackening is required at high temperature; the utility model needs 100% electricity. 2. improve work efficiency: 1-2 minutes. 3. black, low cost, simple equipment, easy to operate, black time has been strictly controlled.

- Q: This question asks about the variety of dimensions and forms that aluminum profiles can come in.

- <p>Aluminum profiles are available in a wide range of sizes and shapes to suit various applications. Common shapes include rectangular, square, circular, and special profiles like angles, channels, and tees. Sizes can vary from thin strips to thick bars, with specific dimensions tailored to the needs of the project. The profiles can be flat, hollow, or have complex cross-sectional geometries. They are also available in different surface finishes, such as anodized, painted, or powder-coated, to enhance their appearance and durability. The selection of aluminum profiles depends on the structural requirements, design specifications, and the industry they are intended for, such as construction, automotive, or aerospace.</p>

- Q: The 50 series and the 60 series of aluminum profiles, which one is good?

- respectively60 of the cross section is larger than 50 1cm, much stronger. The glass gap that can be installed is also larger

- Q: Can aluminum profiles be used in swimming pool enclosures or structures?

- Swimming pool enclosures or structures can indeed utilize aluminum profiles. The popularity of aluminum in constructing these enclosures is owed to its outstanding resistance to corrosion and its durability. Aluminum proves ideal for use in a pool environment due to its ability to resist rust and degradation caused by water and chlorine. Furthermore, the flexibility of aluminum profiles allows for easy shaping, welding, and installation, facilitating the construction of tailored enclosures that meet specific requirements and aesthetics. In addition, the lightweight nature of aluminum profiles makes them convenient to handle and transport during installation. In conclusion, aluminum profiles provide a dependable and enduring solution for swimming pool enclosures or structures.

- Q: Can aluminum profiles be used for automotive roof racks or cargo systems?

- Automotive roof racks or cargo systems can indeed utilize aluminum profiles. Aluminum, a material known for its durability and lightweight properties, is widely employed in the automotive sector owing to its impressive strength-to-weight ratio. Its resistance to corrosion is especially crucial for roof racks as they are exposed to the elements. Moreover, aluminum profiles can be effortlessly molded and tailored to meet specific specifications, rendering them appropriate for diverse cargo system designs. In summary, owing to their strength, lightweight nature, and resistance to corrosion, aluminum profiles are highly favored for automotive roof racks and cargo systems.

- Q: Are there any limitations or drawbacks to using aluminum profiles?

- Yes, there are some limitations and drawbacks to using aluminum profiles. Firstly, aluminum is a relatively soft metal compared to steel, which means it may not be as strong or durable in certain applications. Additionally, aluminum profiles can be more expensive than other materials such as wood or plastic. They also have lower resistance to high temperatures, which can lead to warping or deformation. Finally, aluminum profiles may require additional surface treatments or coatings to protect against corrosion in certain environments.

- Q: What are the surface finishes available for aluminum profiles?

- There are several surface finishes available for aluminum profiles, each offering different aesthetics and properties. Some of the common surface finishes for aluminum profiles include: 1. Mill Finish: This is the standard finish obtained directly from the mill without any additional treatment. It has a raw appearance with visible manufacturing marks and is typically used for structural applications where aesthetics are not a concern. 2. Anodized Finish: This finish involves an electrochemical process that creates a protective oxide layer on the surface of the aluminum, resulting in increased corrosion resistance and durability. Anodized finishes are available in various colors and can provide a glossy or matte appearance, making them popular for decorative applications. 3. Powder Coating: Powder coating involves applying a dry powder onto the aluminum surface and then curing it in an oven. This finish provides excellent durability, corrosion resistance, and a wide range of color options. It can also offer various textures, such as smooth, matte, or textured, allowing for customization according to specific design requirements. 4. Brushed Finish: This finish is achieved by brushing the aluminum surface with abrasive materials to create a pattern of fine lines, giving it a brushed appearance. This finish is commonly used to add a decorative touch to aluminum profiles and can offer a sleek and modern look. 5. Polished Finish: Polishing involves using abrasive materials to create a smooth and shiny surface on the aluminum. This finish can range from a high gloss mirror-like appearance to a satin finish. Polished finishes are often used in architectural applications where a reflective and visually appealing surface is desired. 6. Wood Grain Finish: This finish involves applying a special coating to the aluminum surface, mimicking the appearance of wood grain. It provides a natural and warm look, making it suitable for applications where a wood-like aesthetic is desired without the maintenance requirements of actual wood. These are just a few examples of the surface finishes available for aluminum profiles. The choice of finish depends on the intended application, desired appearance, and specific requirements such as corrosion resistance, durability, and ease of maintenance.

- Q: This question asks for a description of the various dimensions and forms of aluminum profiles that are utilized in siding systems.

- <p>Aluminum profiles for siding systems come in a variety of sizes and shapes to accommodate different architectural styles and structural requirements. Common profiles include flat bars, channels, angles, and Z-profiles. Sizes can range from narrow trims of 10mm to wide panels of over 200mm in width, with thicknesses typically from 0.5mm to 3mm. Shapes are designed for specific functions, such as interlocking for a seamless appearance, or with grooves for attaching insulation. Custom profiles are also available for unique applications. These profiles are chosen based on the building's design, load-bearing needs, and aesthetic preferences.</p>

- Q: Chengdu where to sell aluminum profiles of many businesses?

- Bus route Liang Jia lane to Qingbaijiang on the car, told the driver to Fengxiang market under the line, and 6 yuan fare, cheaper! Drive away the State Road 108 to Mi Mou Town, Fengxiang market in 108 State Road next great, far away saw. This is the latest information, 2013-9-12

- Q: What are the different machining techniques for aluminum profiles?

- For aluminum profiles, there are various machining techniques available depending on the desired result and project specifications. Some commonly used techniques include: 1. Milling: Rotary cutters are used to remove material from the aluminum profile, allowing for the creation of intricate shapes, slots, and holes. This can be done manually or with the assistance of computer numerical control (CNC) milling machines. 2. Drilling: By employing a rotating cutting tool called a drill bit, holes of different sizes and shapes can be made in the aluminum profile. 3. Turning: A stationary cutting tool is utilized while the aluminum profile rotates, resulting in the removal of material and the creation of cylindrical shapes like shafts or rods. 4. Bending: To achieve curved or angled shapes, the aluminum profile is deformed using this technique. It is widely employed in industries such as construction and automotive. 5. Grinding: By applying abrasive particles to the surface of the aluminum profile, material is eliminated and a smooth finish is achieved. This technique is frequently utilized for precise dimensions and high-quality surface finishes. 6. Sawing: The aluminum profile is cut to the desired length or specific shapes using a saw blade. 7. Welding: The edges of two or more aluminum profiles are melted and fused together to form strong and durable joints. This technique is commonly employed in industries like construction and aerospace. These are just a few examples of the numerous machining techniques available for aluminum profiles. The selection of a technique depends on factors such as the desired outcome, design complexity, and project requirements.

Send your message to us

Mill Aluminum Extrusion Profiles Products

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords