Mild Steel Double T Equivalent to I Beam Steel in Middle Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Mild Steel Double T Equivalent to I Beam Description:

Mild steel double T equivalent to I beam is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Mild steel double T equivalent to I beam is usually made of structural steel and is used in construction and civil engineering. The mild steel double T equivalent to I beam resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Mild steel double T equivalent to I beam theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel I Beam Bar IPE Form:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

3. Steel I Beam Bar IPE Images:

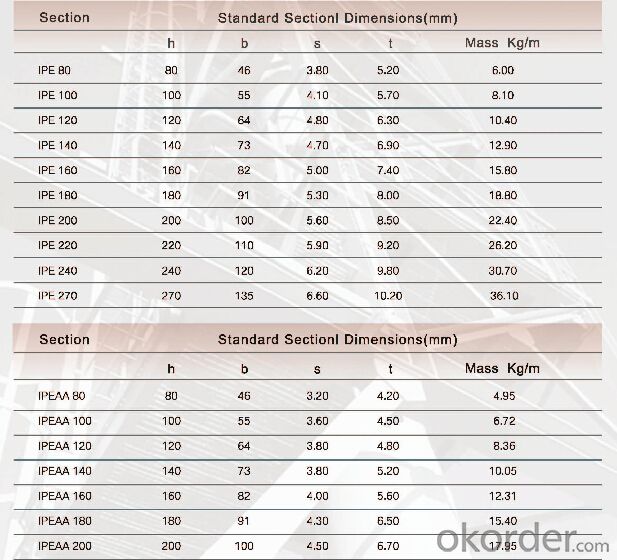

4. Steel I Beam Bar IPE Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: Can steel I-beams be used in the construction of healthcare facilities?

- Yes, steel I-beams can be used in the construction of healthcare facilities. Steel I-beams are commonly used in construction due to their strength, durability, and ability to support heavy loads. They provide structural stability to the building, making them suitable for healthcare facilities where safety and longevity are crucial.

- Q: What's the difference between 25B and 25A I-beam?

- Channel type 25a#, 25b#, 25c# is to indicate "waist height of the same" channel, but its leg width and waist thickness is different, so you need to add a, B, C to the right of the model to be distinguished. For example, 25a# means 250*78*7. 25b# stands for 250*80*9.25c# stands for 250*82*11.

- Q: Channel and I-beam are commonly used in construction sites. It is better to have on-site construction drawings, thank you

- Channel and I-beam are usually used to build floors.

- Q: Are steel I-beams resistant to corrosion?

- Indeed, steel I-beams exhibit exceptional resistance against corrosion. Typically crafted from carbon steel, these beams contain a substantial amount of carbon alongside other elements that heighten their resistance against corrosion. In addition, an extra layer of protection can be applied to steel I-beams through techniques like galvanization or painting. These treatments create a barrier between the steel's surface and its surroundings, effectively preventing direct contact with moisture and other corrosive elements. Consequently, steel I-beams are frequently employed in construction ventures necessitating corrosion resistance, such as the development of bridges, buildings, and other structures exposed to harsh environmental conditions.

- Q: What are the considerations for steel I-beam design in corrosive chemicals environments?

- When designing steel I-beams for corrosive chemical environments, there are several important considerations to take into account. Firstly, it is crucial to select the right type of steel that offers excellent resistance to corrosion. Stainless steel grades, such as 316 or 2205, are commonly chosen for their high corrosion resistance properties. These steels contain alloying elements like chromium and molybdenum, which provide a protective layer against corrosive chemicals. Secondly, the design of the I-beam should incorporate proper protection measures to prevent direct contact between the steel and corrosive chemicals. This can be achieved by using protective coatings, such as epoxy or polyurethane paints, that act as a barrier between the steel and the corrosive environment. Additionally, the use of sacrificial anodes or cathodic protection systems can be employed to further safeguard the steel against corrosion. Another important consideration is the structural integrity of the I-beam. Corrosion can weaken the steel over time, leading to a decrease in load carrying capacity. It is essential to factor in the potential loss of strength due to corrosion and incorporate appropriate safety margins in the design. Regular inspections and maintenance should also be conducted to detect any signs of corrosion and address them promptly. Furthermore, the design should account for the specific type of corrosive chemical present in the environment. Different chemicals have varying degrees of corrosiveness, and some may require additional measures such as specialized coatings or materials to ensure long-term durability. Lastly, it is crucial to adhere to relevant industry standards and guidelines for designing steel structures in corrosive environments. Standards like the American Institute of Steel Construction (AISC) provide guidance on material selection, design considerations, and construction practices specific to corrosive environments. In summary, the considerations for steel I-beam design in corrosive chemical environments involve selecting the appropriate corrosion-resistant steel, implementing protective measures, accounting for potential loss of strength due to corrosion, considering the specific corrosive chemicals present, and following industry standards and guidelines. By addressing these factors, the design can ensure the longevity and safety of the steel I-beams in corrosive environments.

- Q: Can steel I-beams be used to create open floor plans in buildings?

- Steel I-beams possess the capability to fashion open floor plans within buildings. Renowned for their robustness and capacity to span vast distances, these beams prove to be perfect for constructing expansive areas without necessitating supplementary support columns or walls. They can effortlessly bear the weight of multiple floors above, thus enabling the realization of commodious and unobstructed arrangements. Furthermore, steel I-beams frequently find application in commercial and industrial structures desiring capacious open spaces, thereby granting versatility in terms of design and functionality.

- Q: How do you anchor steel I-beams to the foundation?

- To anchor steel I-beams to a foundation, there are several methods commonly used in construction. One common technique is to use anchor bolts or anchor rods. These bolts or rods are typically embedded into the foundation during its construction. The I-beams are then positioned on the foundation, and holes are drilled through the flange plates of the beams to correspond with the anchor bolt locations. The beams are then bolted down to the foundation using nuts and washers, ensuring a secure connection. Another method is the use of epoxy anchors. Epoxy anchors are installed by drilling holes into the foundation and then injecting epoxy resin into the holes. Once the epoxy has cured, steel rods or threaded rods are inserted into the epoxy-filled holes. The I-beams are then secured to these rods using nuts and washers, providing a strong and reliable anchor. In some cases, welding may also be employed to anchor steel I-beams to the foundation. This method involves welding steel plates to the foundation and then welding the I-beams to these plates. Welding provides a permanent and robust connection, but it requires skilled welders and proper welding techniques to ensure structural integrity. The specific method chosen for anchoring steel I-beams to a foundation depends on various factors, such as the load requirements, the foundation type, and the construction regulations applicable in the area. It is crucial to consult with structural engineers and adhere to local building codes to ensure the correct and safe installation of steel I-beams on a foundation.

- Q: What are the common finishes for steel I-beams?

- The common finishes for steel I-beams include hot-dip galvanizing, priming and painting, and powder coating. Hot-dip galvanizing is a process that involves coating the steel I-beam with a layer of zinc, protecting it from corrosion and ensuring its longevity. This finish is commonly used in outdoor applications where the I-beam will be exposed to moisture or harsh environmental conditions. Priming and painting is another common finish for steel I-beams. It involves applying a layer of primer to the surface of the I-beam to enhance adhesion, followed by one or more coats of paint. Priming and painting not only provide a protective barrier against corrosion but also allow for customization in terms of color and appearance. Powder coating is a finish that involves electrostatically applying a dry powder onto the surface of the I-beam. The powder is then cured under heat, forming a hard and durable finish. Powder coating offers excellent corrosion resistance, as well as a wide range of color options and a smooth, even appearance. It is worth mentioning that the choice of finish for steel I-beams depends on the specific requirements of the application. Factors such as the environment, aesthetic preferences, and level of corrosion resistance needed should be taken into consideration when selecting the appropriate finish for steel I-beams.

- Q: What are the different methods of protecting steel I-beams from corrosion?

- There are several methods of protecting steel I-beams from corrosion. One common method is applying a protective coating such as paint or epoxy. These coatings act as a barrier between the steel and the environment, preventing moisture and oxygen from reaching the surface of the beam. Another method is galvanization, which involves coating the steel with a layer of zinc. The zinc acts as a sacrificial anode, corroding instead of the steel and providing long-lasting protection. Additionally, using stainless steel or corrosion-resistant alloys for the I-beams is another effective way to prevent corrosion. Regular maintenance such as cleaning, inspection, and repairing any damaged coatings is also crucial in preserving the integrity of the steel beams and preventing corrosion.

- Q: Can steel I-beams be used in the construction of hotels and resorts?

- Yes, steel I-beams can certainly be used in the construction of hotels and resorts. Steel I-beams are commonly used in the construction industry due to their strength, durability, and versatility. They provide excellent structural support, making them ideal for large-scale projects like hotels and resorts that require sturdy frameworks to support multiple floors, walls, and roofs. Moreover, steel I-beams can handle heavy loads and offer flexibility in design, allowing architects and engineers to create spacious and open layouts for hotels and resorts. Additionally, steel is fire-resistant, which is an important safety consideration for buildings with many occupants. Overall, steel I-beams are a popular choice in the construction of hotels and resorts due to their strength, durability, design flexibility, and fire-resistant properties.

Send your message to us

Mild Steel Double T Equivalent to I Beam Steel in Middle Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords