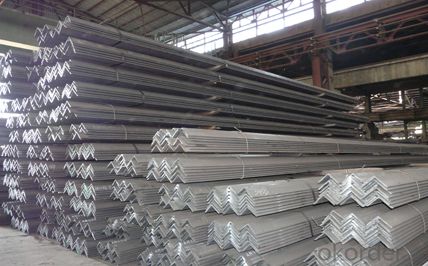

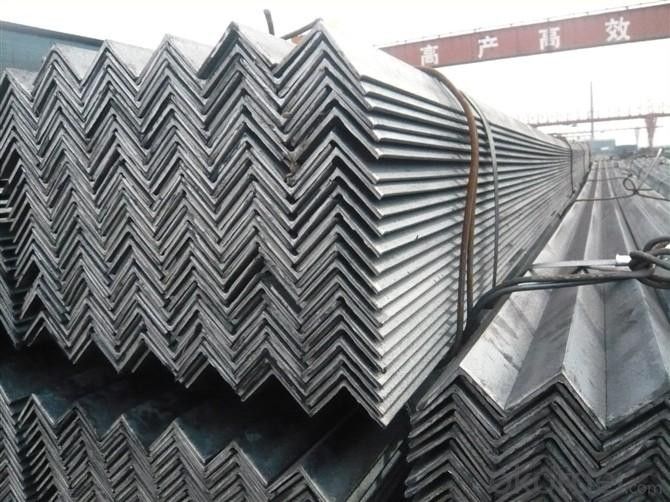

Equal Angle Steel Mild Steel for Infrastructure Project

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Equal Angle Steel Mild Steel for Infrastructure Project at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Equal Angle Steel Mild Steel for Infrastructure Project are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Equal Angle Steel Mild Steel for Infrastructure Project are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Trademark | Rank | Chemical composition (quality score) % | |||||

C | Si | Mn | S | P | |||

≤ | ≤ | ≤ | |||||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | |||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | |||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | ||||||

≤16 | 16-40 | ≤16 | 16-40 | ||||

≥ | ≥ | ||||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

| EQUAL ANGLE STEEL | |||||

| size(mm) | a(mm) | a1(mm) | thickness(mm) | kg/m | length |

| 50*50*4 | 50 | 50 | 4 | 3.059 | 6m,9m,12m |

| 50*50*5 | 50 | 50 | 5 | 3.77 | 6m,9m,12m |

| 50*50*6 | 50 | 50 | 6 | 4.465 | 6m,9m,12m |

| 63*63*5 | 63 | 63 | 5 | 4.822 | 6m,9m,12m |

| 63*63*6 | 63 | 63 | 6 | 5.721 | 6m,9m,12m |

| 65*65*5 | 65 | 65 | 5 | 5 | 6m,9m,12m |

| 65*65*6 | 65 | 65 | 6 | 5.91 | 6m,9m,12m |

| 65*65*8 | 65 | 65 | 8 | 7.66 | 6m,9m,12m |

| 75*75*5 | 75 | 75 | 5 | 5.818 | 6m,9m,12m |

| 75*75*6 | 75 | 75 | 6 | 6.905 | 6m,9m,12m |

| 75*75*8 | 75 | 75 | 8 | 9.03 | 6m,9m,12m |

| 75*75*9 | 75 | 75 | 9 | 9.96 | 6m,9m,12m |

| 75*75*10 | 75 | 75 | 10 | 11.089 | 6m,9m,12m |

| 80*80*6 | 80 | 80 | 6 | 7.375 | 6m,9m,12m |

| 80*80*7 | 80 | 80 | 7 | 8.525 | 6m,9m,12m |

| 80*80*8 | 80 | 80 | 8 | 9.658 | 6m,9m,12m |

| 80*80*10 | 80 | 80 | 10 | 11.874 | 6m,9m,12m |

| 90*90*6 | 90 | 90 | 6 | 8.35 | 6m,9m,12m |

| 90*90*7 | 90 | 90 | 7 | 9.656 | 6m,9m,12m |

| 90*90*8 | 90 | 90 | 8 | 10.946 | 6m,9m,12m |

| 90*90*10 | 90 | 90 | 10 | 13.476 | 6m,9m,12m |

| 100*100*6 | 100 | 100 | 6 | 9.366 | 6m,9m,12m |

| 100*100*7 | 100 | 100 | 7 | 10.83 | 6m,9m,12m |

| 100*100*8 | 100 | 100 | 8 | 12.276 | 6m,9m,12m |

| 100*100*9 | 100 | 100 | 9 | 13.49 | 6m,9m,12m |

| 100*100*10 | 100 | 100 | 10 | 15.12 | 6m,9m,12m |

| 100*100*12 | 100 | 100 | 12 | 17.898 | 6m,9m,12m |

| 120*120*8 | 120 | 120 | 8 | 14.88 | 6m,9m,12m |

| 120*120*10 | 120 | 120 | 10 | 18.37 | 6m,9m,12m |

| 120*120*12 | 120 | 120 | 12 | 21.66 | 6m,9m,12m |

| 125*125*8 | 125 | 125 | 8 | 15.504 | 6m,9m,12m |

| 125*125*10 | 125 | 125 | 10 | 19.133 | 6m,9m,12m |

| 125*125*12 | 125 | 125 | 12 | 22.696 | 6m,9m,12m |

| 130*130*10 | 130 | 130 | 10 | 19.8 | 6m,9m,12m |

| 130*130*12 | 130 | 130 | 12 | 23.6 | 6m,9m,12m |

| 130*130*13 | 130 | 130 | 13 | 25.4 | 6m,9m,12m |

| 130*130*14 | 130 | 130 | 14 | 27.2 | 6m,9m,12m |

| 150*150*10 | 150 | 150 | 10 | 23 | 6m,9m,12m |

| 150*150*12 | 150 | 150 | 12 | 27.3 | 6m,9m,12m |

| 150*150*14 | 150 | 150 | 14 | 31.6 | 6m,9m,12m |

| 150*150*15 | 150 | 150 | 15 | 33.8 | 6m,9m,12m |

| 140*140*10 | 140 | 140 | 10 | 21.49 | 6m,9m,12m |

| 140*140*12 | 140 | 140 | 12 | 25.52 | 6m,9m,12m |

| 140*140*14 | 140 | 140 | 14 | 29.49 | 6m,9m,12m |

| 160*160*10 | 160 | 160 | 10 | 24.73 | 6m,9m,12m |

| 160*160*12 | 160 | 160 | 12 | 29.39 | 6m,9m,12m |

| 160*160*14 | 160 | 160 | 14 | 33.99 | 6m,9m,12m |

| 180*180*12 | 180 | 180 | 12 | 33.16 | 6m,9m,12m |

| 180*180*14 | 180 | 180 | 14 | 39.39 | 6m,9m,12m |

| 180*180*16 | 180 | 180 | 16 | 43.45 | 6m,9m,12m |

| 180*180*18 | 180 | 180 | 18 | 48.63 | 6m,9m,12m |

| 200*200*14 | 200 | 200 | 14 | 42.89 | 6m,9m,12m |

| 200*200*16 | 200 | 200 | 16 | 48.68 | 6m,9m,12m |

| 200*200*18 | 200 | 200 | 18 | 54.4 | 6m,9m,12m |

| 200*200*20 | 200 | 200 | 20 | 60.06 | 6m,9m,12m |

| 200*200*24 | 200 | 200 | 24 | 71.17 | 6m,9m,12m |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Q4: How many tons of steel products could be loaded in containers?

A4: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Images:

- Q: Can steel angles be used as lintels?

- Yes, steel angles can be used as lintels. Steel angles are commonly used in construction as lintels due to their strength and durability. Lintels are structural elements that support the weight of the wall above an opening, such as a door or window. Steel angles are especially suitable for this purpose because they can bear heavy loads and provide excellent structural support. They are often used in masonry construction to create a strong and stable lintel. Additionally, steel angles can be easily customized to fit specific dimensions, making them a flexible choice for lintel applications.

- Q: Are there any limitations on the length-to-thickness ratio of steel angles?

- Yes, there are limitations on the length-to-thickness ratio of steel angles. The length-to-thickness ratio, also known as the slenderness ratio, is an important factor in determining the structural stability and load-bearing capacity of steel angles. The slenderness ratio is calculated by dividing the length of the angle by its thickness. In general, steel angles with a larger length-to-thickness ratio are more prone to buckling or failure under compressive loads. Therefore, there are industry standards and guidelines that specify maximum slenderness ratios for steel angles to ensure structural integrity. The specific limitations on the length-to-thickness ratio of steel angles depend on various factors such as the type of steel, the angle's cross-sectional shape, the applied load, and the intended application. These limitations are typically provided by engineering codes and standards, such as the American Institute of Steel Construction (AISC) or Eurocode, which provide design guidelines for various structural elements including steel angles. It is essential to adhere to these limitations to prevent structural failures and ensure the safety and performance of steel angles in different applications. Structural engineers and designers should consult the relevant codes and standards to determine the appropriate length-to-thickness ratio for specific steel angle designs.

- Q: Can steel angles be used for structural support?

- Yes, steel angles can be used for structural support. Steel angles are often used in construction and engineering projects to provide support and stability to structures. They are commonly used in the construction of buildings, bridges, and other infrastructure. Steel angles are strong and durable, making them suitable for bearing heavy loads and withstanding the forces of compression and tension. Their L-shape design allows for easy installation and connection to other structural elements. Steel angles can be used as beams, columns, braces, and other structural components to provide stability and strength to a structure.

- Q: Can steel angles be used as framing members for suspended ceilings?

- Indeed, framing members for suspended ceilings can be made using steel angles. In construction, steel angles are widely employed due to their robustness and endurance. By serving as framing members, they contribute to the support and stability of the ceiling system. Mounting steel angles onto walls or other structural components is a straightforward task, and they can be easily trimmed to fit the precise dimensions of the ceiling. Furthermore, steel angles can be painted or coated to align with the aesthetic demands of the suspended ceiling. All in all, steel angles prove to be a dependable and appropriate option for framing members in suspended ceilings.

- Q: What are the different methods for cutting steel angles?

- There are several different methods for cutting steel angles, depending on the specific requirements and the tools available. Some of the most common methods include: 1. Manual cutting: This involves using a handheld hacksaw or a metal cutting bandsaw to cut through the steel angle. It is a labor-intensive method and may not be suitable for large-scale projects or precise cuts. 2. Abrasive cutting: This method uses an abrasive wheel or disc to grind through the steel angle. It is commonly done with an angle grinder or a chop saw. Abrasive cutting is faster than manual cutting and can provide reasonably accurate cuts. 3. Plasma cutting: Plasma cutting involves using a high-temperature plasma arc to melt through the steel angle. It is a versatile method that can cut through thick steel angles quickly and accurately. However, it requires specialized equipment and may not be suitable for small-scale or on-site projects. 4. Laser cutting: Laser cutting uses a high-powered laser beam to melt through the steel angle. It is a precise and efficient method that can produce intricate cuts with minimal heat-affected zones. Laser cutting is commonly used in industrial settings and requires specialized equipment. 5. Waterjet cutting: Waterjet cutting utilizes a high-pressure jet of water mixed with abrasive particles to cut through the steel angle. It is a versatile method that can produce precise cuts without generating heat or causing distortion. Waterjet cutting is commonly used in industries where heat-affected zones and material distortion are a concern. 6. Shearing: Shearing involves using a shear machine to apply a cutting force to the steel angle, causing it to fracture along a predetermined line. It is a fast and efficient method for straight cuts and is commonly used for high-volume production. The choice of cutting method depends on various factors such as the size and thickness of the steel angle, the desired accuracy of the cut, the available equipment, and the project requirements. It is important to consider the specific needs and limitations before selecting the most appropriate cutting method.

- Q: How do you prevent rust on steel angles?

- One way to prevent rust on steel angles is by applying a protective coating or paint that acts as a barrier against moisture and oxygen. Additionally, keeping the steel angles dry and storing them in a controlled environment with low humidity can help prevent rust formation. Regular inspections and maintenance, such as cleaning and removing any dirt or corrosion, can also help in preventing rust on steel angles.

- Q: Can steel angles be drilled or cut?

- Indeed, it is possible to drill or cut steel angles. Steel angles, being a flexible structural material, find extensive use in diverse construction and manufacturing endeavors. It is effortless to drill them for the purpose of creating holes for bolts, screws, or other fastening elements. Moreover, steel angles can be fashioned into specific lengths or shapes by employing tools like saws, plasma cutters, or shears. The capacity to drill or cut steel angles renders them exceedingly adaptable and fitting for an extensive array of applications.

- Q: Can steel angles be used for solar panel mounting?

- Solar panel mounting can indeed utilize steel angles. The utilization of steel angles in solar panel mounting systems is prevalent owing to their robustness, longevity, and adaptability. They furnish a stable and secure framework to bear the weight of the solar panels and endure environmental elements such as intense winds and substantial snow loads. Steel angles additionally facilitate effortless modification and positioning of the solar panels to optimize exposure to sunlight. Furthermore, steel angles can be readily tailored and manufactured to meet precise project specifications, rendering them a favored option within the solar sector.

- Q: What are the different surface coating options for steel angles?

- Some different surface coating options for steel angles include galvanization, powder coating, and painting.

- Q: Can steel angles be used for architectural detailing or ornamentation?

- Yes, steel angles can be used for architectural detailing or ornamentation. They are commonly used to add structural support, create unique design elements, and enhance the aesthetic appeal of buildings. Their versatility, strength, and durability make them suitable for various architectural applications.

Send your message to us

Equal Angle Steel Mild Steel for Infrastructure Project

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords