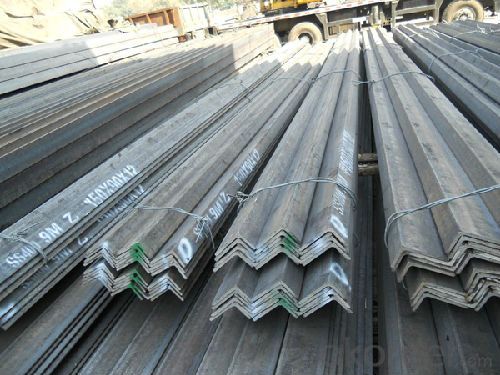

Mild Low Carbon Steel Equal Angles for Wareouses GB, JIS Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Mild Low Carbon Steel Equal Angles for Wareouses GB, JIS Standard at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Mild Low Carbon Steel Equal Angles for Wareouses GB, JIS Standard are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Mild Low Carbon Steel Equal Angles for Wareouses GB, JIS Standard are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1.High quality

2.Suitable price

3.Factory provide directly.

4.Size: 2#-20# /4.5#-20#

Standard:AISI,ASTM,GB,JIS

Dimensions:

1. Equal Angle: 25*25*3mm- 200*200*14/16/18/20mm

2.Unequal Angle: 45*30*4mm-200*125*12/14/16/18mm

Grade:Q235-Q345 Series

Angle steel: equal/Unequal angle bar

| Dimension (mm) | Weight(kg/m) | Dimension (mm) | Weight(kg/m) |

| 20*3 | 0.89 | 80*10 | 11.87 |

| 20*4 | 1.15 | 90*6 | 8.35 |

| 25*3 | 1.12 | 90*7 | 9.66 |

| 25*4 | 1.46 | 90*8 | 10.95 |

| 30*3 | 1.37 | 90*10 | 13.48 |

| 30*4 | 1.79 | 90*12 | 15.94 |

| 36*3 | 1.66 | 100*6 | 9.37 |

| 36*4 | 2.16 | 100*7 | 10.83 |

| 36*5 | 2.65 | 100*8 | 12.28 |

| 40*3 | 1.85 | 100*10 | 15.12 |

| 40*4 | 2.42 | 100*12 | 17.9 |

| 40*5 | 2.98 | 100*14 | 20.61 |

| 45*3 | 2.09 | 100*16 | 23.26 |

| 45*4 | 2.74 | 110*7 | 11.93 |

| 45*5 | 3.37 | 110*8 | 13.53 |

| 45*6 | 3.99 | 110*10 | 16.69 |

| 50*3 | 2.33 | 110*12 | 19.78 |

| 50*4 | 3.06 | 110*14 | 22.81 |

| 50*5 | 3.77 | 125*8 | 15.5 |

| 50*6 | 4.46 | 125*10 | 19.13 |

| 56*3 | 2.62 | 125*12 | 22.7 |

| 56*4 | 3.45 | 125*14 | 26.19 |

| 56*5 | 4.25 | 140*10 | 21.49 |

| 56*8 | 6.57 | 140*12 | 25.52 |

| 63*4 | 3.91 | 140*14 | 29.49 |

| 63*5 | 4.82 | 140*16 | 33.39 |

| 63*6 | 5.72 | 160*10 | 24.73 |

| 63*8 | 7.47 | 160*12 | 29.39 |

| 63*10 | 9.15 | 160*14 | 33.99 |

| 70*4 | 4.37 | 160*16 | 38.52 |

| 70*5 | 5.4 | 180*12 | 33.16 |

| 70*6 | 6.41 | 180*14 | 38.38 |

| 70*7 | 7.4 | 180*16 | 43.54 |

| 70*8 | 8.37 | 180*18 | 48.63 |

| 75*5 | 5.82 | 200*14 | 42.89 |

| 75*6 | 6.91 | 200*16 | 48.68 |

| 75*7 | 7.98 | 200*18 | 54.4 |

| 75*8 | 9.03 | 200*20 | 60.06 |

| 75*10 | 11.09 | 200*24 | 71.17 |

| 80*5 | 6.21 | ||

| 80*6 | 7.38 | ||

| 80*7 | 8.53 | ||

| 80*8 | 9.66 |

| Dimension (mm) | Weight(kg/m) | Dimension (mm) | Weight(kg/m) |

| 25*16*3 | 0.91 | 100*63*6 | 7.55 |

| 25*16*4 | 1.18 | 100*63*7 | 8.72 |

| 32*20*3 | 1.17 | 100*63*8 | 9.88 |

| 32*20*4 | 1.52 | 100*63*10 | 12.1 |

| 40*25*3 | 1.48 | 100*80*6 | 8.35 |

| 40*25*4 | 1.94 | 100*80*7 | 9.66 |

| 45*28*4 | 1.69 | 100*80*8 | 10.9 |

| 45*28*5 | 2.2 | 100*80*10 | 13.5 |

| 50*32*3 | 1.91 | 110*70*6 | 8.35 |

| 50*32*4 | 2.49 | 110*70*7 | 9.66 |

| 56*36*3 | 2.15 | 110*70*8 | 10.9 |

| 56*36*4 | 2.82 | 110*70*10 | 13.5 |

| 56*36*5 | 3.47 | 125*80*7 | 11.1 |

| 63*40*4 | 3.19 | 125*80*8 | 12.6 |

| 63*40*5 | 3.92 | 125*80*10 | 15.5 |

| 63*40*6 | 4.64 | 125*80*12 | 18.3 |

| 63*40*7 | 10 | 140*90*8 | 14.2 |

| 70*45*4 | 3.57 | 140*90*10 | 17.5 |

| 70*45*5 | 4.4 | 140*90*12 | 20.7 |

| 70*45*6 | 5.22 | 140*90*14 | 23.9 |

| 70*45*7 | 6.01 | 160*100*10 | 19.9 |

| 75*50*5 | 4.81 | 160*100*12 | 23.6 |

| 75*50*6 | 5.7 | 160*100*14 | 27.2 |

| 75*50*8 | 7.43 | 160*100*16 | 30.8 |

| 75*50*10 | 9.1 | 180*110*10 | 22.3 |

| 80*50*5 | 5 | 180*110*12 | 26.5 |

| 80*50*6 | 5.93 | 180*110*14 | 30.6 |

| 80*50*7 | 6.85 | 180*110*16 | 34.6 |

| 80*50*8 | 7.75 | 200*125*12 | 29.8 |

| 90*56*5 | 5.66 | 200*125*14 | 34.4 |

| 90*56*6 | 6.72 | 200*125*16 | 39 |

| 90*56*7 | 7.76 | 200*125*18 | 43.6 |

| 90*56*8 | 8.78 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: What does "L125*8" stand for in steel structures?

- Angle steel is divided into equal angle steel and unequal angle steel. The expression of the equal angle steel model is b*d, in which B is the unilateral width of the equilateral angle steel, and the D is the thickness, and the unit is MM. Unequal angles are named by the ratio of the length to the width of a centimeter and the width of a short edge. Therefore, the L125*8 represents an equilateral angle steel beam with a unilateral width of 125 and a thickness of 8. I hope this problem can be solved for you.

- Q: What are the tolerance specifications for steel angles?

- The tolerance specifications for steel angles can vary depending on the specific standards and requirements set by different organizations and industries. However, in general, the tolerance specifications for steel angles typically include measurements for dimensions such as leg length, thickness, and straightness. Leg length tolerance refers to the allowable deviation from the specified leg length of the angle. This tolerance ensures that the angle's legs are within an acceptable range of the desired measurement. For example, a tolerance specification of ±1/8 inch means that the leg length can deviate by up to 1/8 inch in either direction from the specified dimension. Thickness tolerance indicates the permissible deviation in the thickness of the steel angle. This specification ensures that the thickness is consistent and within an acceptable range. It is typically expressed as a percentage or an absolute value. For instance, a tolerance specification of ±10% means that the thickness can deviate by up to 10% above or below the specified dimension. Straightness tolerance ensures that the steel angle is not bent or twisted and meets the required straightness criteria. It is usually measured by the maximum allowable deviation from the straight line. This tolerance specification guarantees that the angle can be easily fitted and aligned during construction or manufacturing processes. It is important to note that the specific tolerance specifications for steel angles may vary depending on the intended application, industry standards, and regulatory requirements. Therefore, it is recommended to refer to the relevant standards, codes, or specifications provided by the manufacturer, industry associations, or governing bodies for accurate and up-to-date information on the tolerance specifications for steel angles.

- Q: How do you join two steel angles together?

- To join two steel angles together, there are several methods you can use depending on the specific application and requirements. Here are a few common techniques: 1. Welding: Welding is the most common method used to join steel angles. It involves heating the joint to a high temperature and melting a filler material, usually a compatible metal, to fuse the two angles together. This creates a strong and permanent bond. Welding requires specialized equipment and expertise, so it is typically done by trained professionals. 2. Bolting: Another method is to use bolts or screws to connect the two steel angles. This involves drilling holes through both angles and then securing them with appropriate fasteners. Bolting allows for easier disassembly and modification if needed. However, it may not provide the same level of strength as welding. 3. Riveting: Riveting is a technique that uses metal pins or bolts called rivets to hold the steel angles together. It involves drilling holes through the angles and inserting the rivets, which are then hammered or pressed to form a permanent joint. Riveting is commonly used in structural applications where high strength and load-bearing capacity are required. 4. Adhesive bonding: In some cases, adhesive bonding can be used to join steel angles. Specialized adhesives are applied to the joint surfaces, and then the angles are pressed together and left to cure. This method can provide a clean and aesthetically pleasing bond, but it may not be as strong as other mechanical methods. When selecting a method to join steel angles, it is important to consider factors such as the load-bearing requirements, structural integrity, accessibility, and the specific conditions of the application. Consulting with a structural engineer or a professional in the field can help determine the most suitable technique for your specific needs.

- Q: What are the standard tolerances for steel angles?

- The standard tolerances for steel angles can vary depending on the specific grade and size of the angle. However, in general, the standard tolerances for steel angles include dimensional tolerances and straightness tolerances. Dimensional tolerances refer to the allowable variations in the dimensions of the steel angle, such as the thickness, width, and length. These tolerances are typically expressed as a range or a maximum allowable deviation from the specified dimensions. Straightness tolerances, on the other hand, refer to the allowable deviation from a straight line that the steel angle can have. This is typically measured by placing a straight edge along the length of the angle and measuring the maximum gap between the straight edge and the angle. It is important to note that the specific tolerances for steel angles should be determined based on the applicable standards and specifications, such as those provided by industry organizations or regulatory bodies. These standards and specifications will provide the necessary guidance on the acceptable tolerances for steel angles based on their intended use and application.

- Q: 304 what does angle iron stand for?

- 304 stainless steel, consisting of 18Cr-9Ni, is the most widely used stainless steel and heat resistant steel. Used in food production equipment, chemical equipment, nuclear energy, etc..

- Q: How can steel angles be cut to size?

- Steel angles can be cut to size using various methods such as sawing, shearing, or plasma cutting.

- Q: Can steel angles be used in fencing?

- Indeed, fencing can make use of steel angles. Steel angles find frequent application in fencing scenarios, serving to furnish structural reinforcement and stability. Their utility ranges from functioning as posts to serving as crossbars, contingent upon the particular design of the fencing. Steel angles possess robustness and durability, rendering them well-suited for enduring various elements whilst guaranteeing security. Through facile welding or bolting, steel angles can effortlessly be conjoined to construct a resilient fencing structure. Furthermore, steel angles can be galvanized or coated, augmenting their resistance to rust and corrosion, thereby securing a fencing solution that endures for a prolonged period with minimal maintenance.

- Q: How do you prevent steel angles from twisting?

- There are several methods that can be employed to prevent steel angles from twisting: 1. Proper fabrication techniques: Ensure that the steel angles are fabricated accurately and precisely, with straight and square cuts. This will help maintain the structural integrity of the angles and prevent them from twisting. 2. Bracing and supports: Use appropriate bracing and supports during the installation process to provide stability to the steel angles. These can include temporary supports, diagonal bracing, or cross bracing, depending on the specific application. 3. Welding techniques: When joining steel angles together, use proper welding techniques to minimize distortion and twisting. This includes using the correct welding process, ensuring proper heat control, and employing suitable fixturing to hold the angles in place during the welding process. 4. Anchoring methods: Depending on the specific application, anchoring methods such as bolting, screwing, or welding the steel angles to other structural elements can help prevent twisting. These anchoring methods provide additional stability and prevent the angles from rotating or twisting under external forces. 5. Regular inspections and maintenance: Conduct regular inspections to identify any signs of twisting or distortion in the steel angles. If any issues are detected, take immediate corrective action to rectify the problem and prevent further twisting. Overall, a combination of accurate fabrication, proper bracing and supports, appropriate welding techniques, anchoring methods, and regular maintenance can effectively prevent steel angles from twisting and ensure their structural stability.

- Q: What are the different types of steel angle connections used in seismic design?

- Seismic design incorporates various types of steel angle connections that are commonly utilized. These connections are specifically engineered to withstand the forces and movements experienced during seismic events. Several types of steel angle connections used in seismic design are as follows: 1. Bolted Flange Plate Connection: This connection involves the bolting of a steel plate to the flanges of two angle sections. It demonstrates excellent resistance against lateral and vertical forces while accommodating rotational movements. 2. Welded Flange Plate Connection: Similar to the bolted flange plate connection, this connection entails the welding of a steel plate to the flanges of two angle sections. It offers superior strength and stiffness but is less ductile when compared to the bolted version. 3. Extended Single Plate Connection: This connection is established by extending a single plate beyond the flanges of two angle sections and welding it to both flanges. It provides commendable resistance against lateral and vertical forces while accommodating some degree of rotation. 4. Double Angle Connection: In this connection, two angle sections are joined together using bolts or welds. It possesses high strength and stiffness, effectively resisting lateral and vertical forces. 5. Diagonal Brace Connection: This connection involves connecting diagonal braces to the flanges of two angle sections. It enhances resistance against lateral forces and effectively controls building sway during seismic events. 6. Gusset Plate Connection: This connection employs a gusset plate to connect two or more angle sections. It demonstrates good strength and stiffness while effectively resisting lateral and vertical forces. Each of these steel angle connections possesses its own advantages and disadvantages. The choice of connection relies on factors such as structural design requirements, loadings, and the level of seismic activity in the region. It is crucial to carefully consider these factors and seek consultation with structural engineers to ensure the appropriate connection type is employed for a seismic design project.

- Q: What are the design considerations for using steel angles in architectural applications?

- When considering the use of steel angles in architectural applications, there are several important design considerations to keep in mind. First and foremost, it is crucial to understand the structural requirements of the application. Steel angles can provide excellent strength and stability, but their suitability for a particular design will depend on factors such as the load-bearing capacity needed and the structural stability required. It is important to consult with a structural engineer to determine the appropriate size, shape, and thickness of the steel angles to ensure they can safely support the intended loads. Another consideration is the aesthetic appeal of the steel angles. While they are primarily chosen for their structural properties, they can also contribute to the overall design and visual impact of a building. Architects can choose from a variety of finishes, including painted, galvanized, or even stainless steel angles, to achieve the desired look. The shape and arrangement of the angles can also be used creatively to enhance the architectural design and create unique visual effects. Durability is another important design consideration. Steel angles are known for their strength and resistance to corrosion, which makes them suitable for various architectural applications. However, depending on the environmental conditions, additional protective measures may be required to prevent rusting or deterioration over time. This can include applying protective coatings or ensuring proper drainage to prevent water accumulation. Ease of fabrication and installation is also an essential consideration. Steel angles can be easily fabricated into various shapes and sizes, allowing for flexibility in design. They can be cut, welded, or bent to meet the specific requirements of the architectural application. Additionally, their standardized sizes and availability make them relatively easy to source and install. Finally, cost considerations should not be overlooked. Steel angles are generally cost-effective compared to other structural materials, such as wood or concrete. However, the overall cost will depend on factors such as the size, finish, and quantity of steel angles required. It is important to strike a balance between the desired design and the available budget. In conclusion, when considering the use of steel angles in architectural applications, it is essential to carefully assess the structural requirements, aesthetics, durability, ease of fabrication and installation, and cost considerations. By taking these design considerations into account, architects can make informed decisions and ensure the successful integration of steel angles into their designs.

Send your message to us

Mild Low Carbon Steel Equal Angles for Wareouses GB, JIS Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords