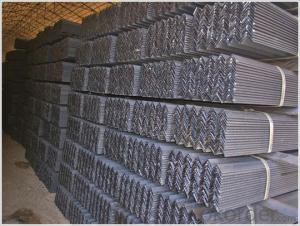

Hot Rolled Steel Angle with Good Quality with The Size 120*120mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application: Hot Rolled Angle Steel is widely used in many fields like the communication tower, beam and rafters of the houses,and bridge. And it is also can be used to be the connection material between different steel structure parts.

Features:

Different Sizes: 50*50mm---250*250mm

Different Standards:GB Standard, JIS Standard, En Standard

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

- Q: Can steel angles be used for door frames?

- Yes, steel angles can be used for door frames. Steel angles provide strength and stability, making them a suitable choice for supporting and reinforcing door frames.

- Q: How are steel angles cut to specific lengths?

- Steel angles can be cut to specific lengths using various tools and methods such as sawing, shearing, or using a plasma cutting machine. These techniques allow for precise and accurate cuts based on the required measurements.

- Q: Can steel angles be used in load-bearing columns?

- Yes, steel angles can be used in load-bearing columns. Steel angles are often used in construction for their strength and durability. They provide structural support and can be used to reinforce load-bearing columns. The angle shape of the steel allows for greater stability and load-bearing capacity compared to other materials. Steel angles are commonly used in the construction of buildings, bridges, and other structures where load-bearing columns are required.

- Q: Where can steel angles be purchased?

- Steel angles can be purchased from a variety of sources. One option is to visit a local hardware store or building supply center that specializes in construction materials. These stores typically carry a wide range of steel products, including steel angles. Another option is to search online for suppliers or distributors that specialize in steel products. Many online retailers offer a wide selection of steel angles and provide the convenience of shopping from home. Additionally, contacting local steel fabrication companies or metal suppliers could be a good option, as they often sell steel angles in various sizes and grades. It is recommended to compare prices, quality, and reviews before making a purchase to ensure getting the best deal and product suitable for the intended use.

- Q: Can steel angles be used for foundation supports?

- Indeed, foundation supports can utilize steel angles. In construction endeavors, steel angles are frequently employed to furnish structural support and stability. Possessing the capacity to endure substantial burdens and offer longevity, steel angles prove themselves ideal for foundation supports. Furthermore, steel angles can be effortlessly linked to other structural elements, like beams or columns, to establish a steadfast foundation system. Moreover, steel angles can be tailored and manufactured to precise measurements and proportions, guaranteeing they conform to the unique prerequisites of the foundation design.

- Q: What is the maximum allowable tensile stress for a steel angle?

- The maximum allowable tensile stress for a steel angle depends on various factors such as the specific grade of steel, the manufacturing process, and the intended application. Steel angles are commonly used in construction and structural applications, and their maximum allowable tensile stress is typically determined by industry standards and design codes. For example, in the United States, the American Institute of Steel Construction (AISC) provides design specifications for structural steel angles. According to AISC, the maximum allowable tensile stress for a steel angle is typically based on the yield strength of the steel material. The yield strength refers to the stress at which a material begins to deform permanently. It is usually specified in terms of pounds per square inch (psi) or megapascals (MPa). Steel angles are typically designed to operate within a certain percentage of their yield strength to ensure structural integrity and safety. In general, the maximum allowable tensile stress for a steel angle is often limited to a percentage of its yield strength, typically ranging from 50% to 70%. This means that the maximum tensile stress that can be applied to a steel angle is a fraction of its yield strength. It is crucial to consult the appropriate design standards and codes, such as those provided by AISC or other relevant organizations, to determine the specific maximum allowable tensile stress for a given steel angle in a particular application. These standards consider factors such as load conditions, safety factors, and environmental conditions to ensure the structural integrity and reliability of the steel angle.

- Q: Can steel angles be used in the construction of power plants?

- Yes, steel angles can be used in the construction of power plants. Steel angles are commonly used in structural applications and are well-suited for supporting heavy loads and providing structural stability. In power plant construction, steel angles can be utilized for various purposes such as framing structural components, supporting equipment and machinery, reinforcing concrete structures, and providing structural integrity to the overall plant infrastructure. Additionally, steel angles offer excellent resistance to corrosion, which is particularly important in power plants where exposure to high temperatures, moisture, and chemicals is common. Overall, the versatility, strength, and durability of steel angles make them a suitable choice for use in the construction of power plants.

- Q: What are the limitations of using steel angles in corrosive or saltwater environments?

- The susceptibility of steel angles to corrosion limits their use in corrosive or saltwater environments. Since steel is mostly made up of iron, it can react with oxygen and water to form rust, or iron oxide. This corrosion process is accelerated in the presence of corrosive substances or saltwater. In these environments, there are a couple of limitations to consider. One limitation is the potential for accelerated corrosion. This can weaken the structural integrity of the steel angles, compromising the overall stability and safety of any structure they are used in. This is particularly concerning when the steel angles are load-bearing or subjected to significant stress. Another limitation is the shortened lifespan of steel angles in corrosive or saltwater environments. The ongoing corrosion process significantly reduces their lifespan, leading to more frequent maintenance or replacement needs. This can result in higher costs and potential disruptions to operations or projects. Additionally, the appearance of steel angles can be negatively affected by corrosion in corrosive or saltwater environments. The surface of the steel can develop rust stains, which are aesthetically unappealing, especially when the steel angles are visible. To overcome these limitations, alternative materials can be considered for corrosive or saltwater environments. For example, stainless steel contains a high proportion of chromium, which gives it enhanced corrosion resistance. Additionally, protective coatings or treatments like galvanizing or epoxy coatings can be applied to steel angles to create an extra barrier against corrosion. In conclusion, although steel angles are versatile and commonly used in various applications, their use in corrosive or saltwater environments is limited due to their susceptibility to corrosion. It is important to carefully assess the specific environment and explore alternative materials or protective measures to ensure the longevity and integrity of any structure or project.

- Q: Are steel angles suitable for architectural cladding?

- Yes, steel angles can be suitable for architectural cladding. Steel angles offer structural support and can be used to create clean lines and sharp corners in architectural designs. They are durable, weather-resistant, and can be customized to match the desired aesthetic. Additionally, steel angles provide versatility in terms of installation and can be easily attached to different building materials.

- Q: What is the maximum length of a steel angle available in the market?

- The maximum length of a steel angle available in the market can vary depending on the manufacturer and specific requirements, but it is typically around 20 feet (6.1 meters).

Send your message to us

Hot Rolled Steel Angle with Good Quality with The Size 120*120mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords