Mica Parts Usded in Electric Arc Furnace Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

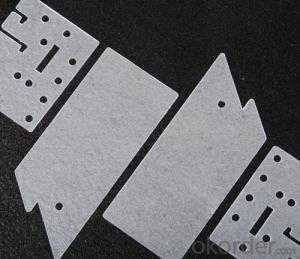

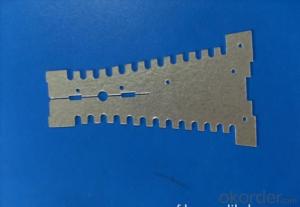

1. Introduction:

Mica is a rigid substrate able to withstand very high temperatures and are suited for applications up to 500°F (260°C). Mica heating elements offer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures. Our mica heating element is made by detail order requirments.

Mica plate is made of mica paper with highperformance organic silicon resin. After heating and pressing, the mica plate can be made into rigid or flexible insulating plates. The mica content is about 90% and the organic silicon resin content is 10%.

2. Applications:

Typical applications of mica heating elements are air heaters, enclosure systems, food service equipment, process and packaging equipment.

3. Main features of Mica Parts:

Mica heating elements offer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures.

4. Technical Parameters:

MICA SHEET -----Technical data | ||||||||

ITEM | UNIT | RM | RP | RM-T | RP-T | FM | FP | |

Hardness |

| Rigid | Rigid | Rigid | Rigid | Flexible | Flexible | |

Mica paper |

| Muscovite | Phlogopite | Muscovite | Phlogopite | Muscovite | Phlogopite | |

Thickness | mm | 0.1-2.0 | 0.1-2.0 | 3.0-50 | 3.0-50 | 0.1-2.0 | 0.1-2.0 | |

Mica content | % | ≥90 | ≥90 | >88 | >88 | ≥90 | ≥90 | |

Bond Content | % | <10< span=""> | <10< span=""> | <12< span=""> | <12< span=""> | <10< span=""> | <10< span=""> | |

Density | g/m 3 | 1.6~2.45 | 1.6~2.45 | 2.1~2.4 | 2.1~2.4 | 1.6~2.45 | 1.6~2.45 | |

Heat | Continuous | ℃ | 500 | 700 | 500 | 700 | 500 | 700 |

Peak | ℃ | 700 | 900 | 700 | 900 | 700 | 900 | |

Heat loss at 500℃ | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | <1< span=""> | <1< span=""> | |

Heat loss at 700℃ | % | <2< span=""> | <2< span=""> | <1< span=""> | <2< span=""> | <2< span=""> | <2< span=""> | |

Flexural strength | Mpa | >160 | >140 | — | — | <1< span=""> | <1< span=""> | |

Water absorption 24h/23°C | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | — | — | |

Dielectric strength | KV/mm | >20 | >20 | >15 | >15 | >15 | >15 | |

Volume | 23℃ | ΩNaN | >1017 | >1017 | >1017 | >1017 | — | — |

500℃ | ΩNaN | >1012 | >1012 | >1012 | >1012 | — | — | |

Smoking Test | s | <4< span=""> | <4< span=""> | — | — | — | — | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of mica parts?

Mica laminate and washers made of our own high quality mica plates are used for home appliances, electro-magnets, micro-sensitive control gear etc

---------Which type of mica parts we can produce?

1. Rigid mica parts or Flexible mica parts

2. Muscovite mica parts or phlogopite mica parts

3. Thin mica parts or thick mica parts

4. All the special sized mica parts need drawing.

----------what advantages of mica parts?

1. Good high voltage insulation materials

2. Do not easily break up

3. Easily produce special size

- Q: There are a lot of online about this, but still do not understand. If the insulation resistance is high enough, hit the pressure should also be qualified ah. There is insulation test itself when the current flow is not large, because the rock table resistance is great. But hit the pressure, I do not know is not a direct high pressure drop in the test product above, there is no great resistance to interference?

- Insulation test Because the test voltage is low, it is not easy to damage the equipment under test. The voltage test is easy to damage the equipment under pressure when the test voltage is high. In some cases, although the withstand voltage test is passed, Causing damage, the test staff will have to use low-voltage insulation test, test the pressure test after the test equipment insulation. Under normal circumstances, insulation resistance qualified, withstand voltage test will be adopted.

- Q: What type of enameled wire and insulation material is used for the compressor

- Enclosed wire and insulation materials for fully enclosed compressors: 1) Refrigerant R12, enameled wire with high strength polyester QZ, insulated with 6400 epoxy resin Insulation H34-4, Polyurethane film for insulating material Green paper (DMD ) Insulation paper; 2) refrigerant R22 and R502, with QF, QXY polyamide imide enameled wire, insulation treatment with EIU epoxy modified impregnated varnish, insulating material with polyimide film and poly Fiber composite foil, F-class insulation DMD insulation paper.

- Q: Who knows what are the ability of 1300 degrees above the high temperature, insulation materials?

- Where the ablative material is also high temperature resistant material. For example, in the 300 ~ 600 ℃, in the air to maintain its mechanical strength, chemical resistance and so on.

- Q: What insulating materials do you need for power tools?

- Insulation system of power tools can be divided into basic insulation, additional insulation, reinforced insulation, double insulation. Basic insulation: enameled wire and iron core between the insulating paper (paper for the green paper or DMD insulation paper) is the basic insulation, Withstand voltage is 1250V;

- Q: What insulating materials are used for high frequency transformers?

- Which is divided into solvent and solvent-free paint is divided into two major categories, mainly used for dipping motor, electrical coil and insulation parts to fill its gap and microporous, immersion paint can be cured in the surface of the formation of continuous formation Of the film, and the coil into a solid as a whole, in order to improve the insulation structure of the moisture, thermal conductivity, dielectric strength and mechanical strength of the performance.

- Q: What is the insulating material in the middle of the connecting wire?

- Looked for a long time to understand your problem, I can see with a relatively thin tube into the insulation, the insulation tube into a plug in the insulation of the skin. Or for the wire, without the foreskin of the wire is not safe

- Q: What are the gas insulation materials?

- In addition to air, nitrogen, carbon dioxide and sulfur hexafluoride gas, there are other gases used for insulation. CCl2F2 (freon-12) was used as an insulating in certain high-energy physical devices. CCl2F2 breakdown strength and SF6 similar, but because of its high liquefaction temperature, and the spark will make CCl2F2 precipitation of carbon particles, therefore, has been replaced by SF6. In hydrogen-cooled generators, hydrogen is also used as insulation in addition to cooling media.

- Q: What is the DMD insulation material?

- DMD insulating paper, the product is a layer of polyester film coated with adhesive, one side for the polyester fiber non-woven composite, calendering from a composite insulation products, referred to as DMD.

- Q: What are the electrical insulation materials

- Insulation material is electrical insulation material. According to the national standard GB2900.5 provides the definition of insulating material is: "used to make the device in the electrical insulation of the material." That is, to prevent the current through the material. Its resistivity is very high, usually in the range of 10 ^ 9 ~ 10 ^ 22Ω · m. As in the motor, the insulating material around the conductor isolates the turns and isolates it from the grounded stator core to ensure safe operation of the motor.

- Q: What insulating material is best `?

- According to their polarity is divided into weak polarity, non-polarity, polarity and strong polarity 4. According to the material source is divided into mineral insulating oil, synthetic insulating oil and vegetable oil 3. Mineral insulating oil referred to as mineral oil, The relative dielectric constant is about 2.2, and the breakdown voltage in the standard electrode is 35 to 50 kV (kV). The flash point is 125 to 135 ° C for the manufacture of transformers and cables , Capacitors, etc. Synthetic insulating oil is a synthetic liquid insulating material.As the mineral oil is a mixture of various hydrocarbons, it is difficult to remove the components of the insulation performance, and the preparation process is complex, easy to burn, low heat resistance , The dielectric constant is not high, so the research and development of the excellent performance of the synthetic insulating oil. Now have used aromatic synthetic oil, silicone oil, ester oil, ether and sulfone synthetic oil, polybutylene, etc. Vegetable oil use Castor oil, soybean oil, rapeseed oil, etc. Castor oil is an excellent dip capacitor for pulse capacitors

Send your message to us

Mica Parts Usded in Electric Arc Furnace Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords