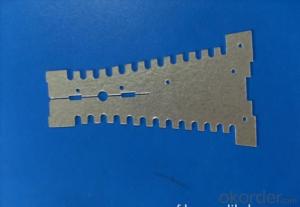

Mica Parts Used in Industry for Air Heater

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction

Mica is a rigid substrate able to withstand very high temperatures and are suited for applications up to 500°F (260°C).

2.Main features of Mica Parts:

Mica heating elementsoffer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures. Our mica heating element is made by detail order requirments.

3. Applications:

Typical applications of mica heating elements are air heaters, enclosure systems, food service equipment, process and packaging equipment.

4. Technical Parameters:

MICA SHEET -----Technical data | ||||||||

ITEM | UNIT | RM | RP | RM-T | RP-T | FM | FP | |

Hardness |

| Rigid | Rigid | Rigid | Rigid | Flexible | Flexible | |

Mica paper |

| Muscovite | Phlogopite | Muscovite | Phlogopite | Muscovite | Phlogopite | |

Thickness | mm | 0.1-2.0 | 0.1-2.0 | 3.0-50 | 3.0-50 | 0.1-2.0 | 0.1-2.0 | |

Mica content | % | ≥90 | ≥90 | >88 | >88 | ≥90 | ≥90 | |

Bond Content | % | <10< span=""> | <10< span=""> | <12< span=""> | <12< span=""> | <10< span=""> | <10< span=""> | |

Density | g/m 3 | 1.6~2.45 | 1.6~2.45 | 2.1~2.4 | 2.1~2.4 | 1.6~2.45 | 1.6~2.45 | |

Heat | Continuous | ℃ | 500 | 700 | 500 | 700 | 500 | 700 |

Peak | ℃ | 700 | 900 | 700 | 900 | 700 | 900 | |

Heat loss at 500℃ | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | <1< span=""> | <1< span=""> | |

Heat loss at 700℃ | % | <2< span=""> | <2< span=""> | <1< span=""> | <2< span=""> | <2< span=""> | <2< span=""> | |

Flexural strength | Mpa | >160 | >140 | — | — | <1< span=""> | <1< span=""> | |

Water absorption 24h/23°C | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | — | — | |

Dielectric strength | KV/mm | >20 | >20 | >15 | >15 | >15 | >15 | |

Volume | 23℃ | ΩNaN | >1017 | >1017 | >1017 | >1017 | — | — |

500℃ | ΩNaN | >1012 | >1012 | >1012 | >1012 | — | — | |

Smoking Test | s | <4< span=""> | <4< span=""> | — | — | — | — | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of mica parts?

Mica laminate and washers made of our own high quality mica plates are used for home appliances, electro-magnets, micro-sensitive control gear etc

---------Which type of mica parts we can produce?

1. Rigid mica parts or Flexible mica parts

2. Muscovite mica parts or phlogopite mica parts

3. Thin mica parts or thick mica parts

4. All the special sized mica parts need drawing.

----------what advantages of mica parts?

1. Good high voltage insulation materials

2. Do not easily break up

3. Easily produce special size

- Q: The electrical equipment in the classroom which uses insulating material

- Insulation material description: Insulation material is electrical insulation material. According to the national standard GB2900.5 provides the definition of insulating material is: "used to make the device in the electrical insulation of the material." That is, to prevent the current through the material. Its resistivity is very high, usually in the range of 10 ^ 9 ~ 10 ^ 22Ω · m. As in the motor, the insulating material around the conductor isolates the turns and isolates it from the grounded stator core to ensure safe operation of the motor.

- Q: What is the 8 ° C rule for insulating materials?

- Insulation material 8 ℃ rules: Insulation material used in the temperature exceeds the limit temperature, the insulation material will quickly deteriorate, the service life will be greatly reduced.

- Q: What type of enameled wire and insulation material is used for the compressor

- Closed compressor, or semi-enclosed compressor, motor stator coil, and refrigerant, frozen oil have direct contact, refrigerant, frozen oil will not damage the insulation of the coil, enameled wire insulation material problems The Small to the refrigerator, freezer compressor, air conditioning compressor, large to semi-closed, fully enclosed chillers, are related to the coil insulation material. To tell the truth I only demolished medium-sized compressors (semi-enclosed compressors for cold storage). Large semi-enclosed high-pressure refrigeration compressor (6KV, 10KV) I only seen in the manufacturer, did not break

- Q: Insulation material and the definition of the role of the best professional insulation materials website for my reference

- The main indicators affect the performance of insulating materials 1, insulation resistance, resistivity: resistance is the reciprocal of conductance, the resistivity is the resistance per unit volume. The smaller the conductivity of the material, the greater the resistance, the reciprocal relationship between the two, for the insulation material, always want the resistivity as high as possible. 2, the relative dielectric constant and dielectric loss tangent:

- Q: What insulating materials are used for high frequency transformers?

- Can be brush, can be sprayed, can be baked Here is the main raw material for ice making. Selection of industrial products. All around the paint factory production. General high-frequency transformer insulation materials used by the scope and form are divided into: impregnated paint, covering paint, silicon steel paint, anti-corona paint four.

- Q: What is the insulating material in the middle of the connecting wire?

- The original wire is insulated paint, you often use, you can also use quick-drying insulating paint.

- Q: What are the gas insulation materials?

- Gas insulation material refers to air, nitrogen, sulfur hexafluoride and other gases

- Q: What are the commonly used insulating materials?

- Mostly used to make insulating varnishes, winding wires, etc. Insulation materials are made of the above two kinds of materials made of various molding insulation materials, used as electrical appliances of the base, shell and so on.

- Q: Wear-resistant, high temperature, insulation materials which

- Epoxy, temperature from 100-400 degrees, processing more convenient. Ceramic is the best and cheap.

- Q: What are the electrical insulation materials

- Insulation board: plastic plate is made of plastic sheet, plastic for the synthesis of polymer compounds, can be free to change the body style. Plastic is the use of monomer raw materials to synthesis or condensation reaction polymerization of materials, synthetic resin and filler, plasticizers, stabilizers, lubricants, colorants and other additives, and its main component is synthetic resin.

Send your message to us

Mica Parts Used in Industry for Air Heater

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords