Mica Boards

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 TON m.t.

- Supply Capability:

- 100TON/MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

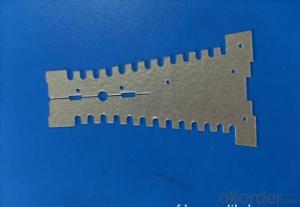

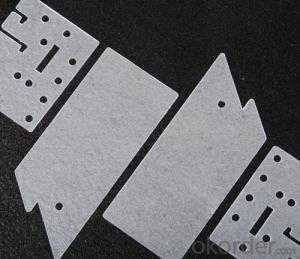

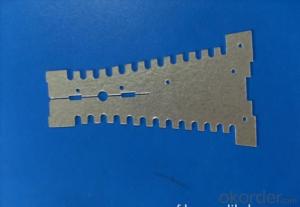

Specifications of Mica Board

Mica Board 1.Free sample 2.Color: White, blue, black 3.Size:customizedceipt of customer remittance

Features of Mica Board

•Excellent resistance to heat up to 1000°C. It has unique temperature resistance,

the maximum working temperature for the Muscovite Mica Plate and Phlogopite Mica

Plate are approximately 500 °C and 750°C respectively,Peak work temperature are

750 °C and 1000 °C respectively.

•Excellent electrical insulation. It has excellent dielectric properties, the maximum

dielectric is more than 20KV/mm.

•Excellent punchability. It has good flexural strength and can be cut very precisely

using die-stamping.

•Environmentally safe. It generates very little smoke even at excessive temperatures

Available

Size: Sheets of 1000 x 600 mm 1000 x 1200 mm 1000 x 2400mm

Strips and punched parts according to drawings for thickness 0, 1 to 2 , 0 mm .

Thickness: 0, 1mm , 0.15mm , 0.2mm , 0.25mm , 0.3mm , …… 5.0mm .

- Q: The electrical equipment in the classroom which uses insulating material

- Insulation material characteristics: chemical resistance with gloss, some transparent or translucent most of the good insulator light weight and strong processing can be easily mass production, cheap and wide range of uses, utility, easy to color, some high temperature

- Q: What is the electrical performance of insulating materials

- The electrical insulating material is a material that is electrically insulated from the device and has a certain mechanical strength, typically having a resistivity of 106 to 1019.cm. Their function in electrical technology is as follows: 1 Insulate the conductor from the other parts; 2 Separate the conductors of different potentials 3 Provide the conditions for the energy storage of the capacitor 4 Improve the potential gradient in the high voltage electric field.

- Q: What type of enameled wire and insulation material is used for the compressor

- Motor insulation class The insulation class is divided according to the permissible limit temperature of the insulation material used for the motor. There are Y, A, E, B, F, H, C and several other levels, the allowable limit temperature at all levels as shown in the table below. The so-called permissible limit temperature refers to the permissible maximum operating temperature of the motor insulation material, which reflects the heat resistance of the insulating material. Insulation material is divided into Y grade, A grade, grade E, grade B, grade F, grade H, grade C, permissible temperature (℃) 90,105,120,130,155,180, 180 ℃ or higher.

- Q: Insulation material and the definition of the role of the best professional insulation materials website for my reference

- The main indicators affect the performance of insulating materials 1, insulation resistance, resistivity: resistance is the reciprocal of conductance, the resistivity is the resistance per unit volume. The smaller the conductivity of the material, the greater the resistance, the reciprocal relationship between the two, for the insulation material, always want the resistivity as high as possible. 2, the relative dielectric constant and dielectric loss tangent:

- Q: What insulating materials are used for transformers

- Dry type transformers before the 1960s are mainly B-type insulation of the open-type dry-type transformers, product model for the SG type. When there is no foil coil, the low pressure for the majority of multi-root and around the layer or spiral coil, high pressure for the pie coil. Wire for the double glass envelope or single glass fiber package enamel enameled wire. The rest of the insulating material is mostly phenolic glass fiber materials. The impregnation process for the room temperature, atmospheric pressure with B-class insulation impregnated paint were high and low pressure coil impregnation and drying at the temperature (drying temperature does not exceed 130 ℃). Although this dry-type transformers than oil-immersed transformers in the fire performance has made great progress, but its moisture, anti-pollution performance is worrying. Is no longer produced. Nevertheless, its successful electrical, magnetic, thermal calculations and structural design have laid a good foundation for the new H-class insulated open-ended transformers that have evolved later.

- Q: What insulating material is used for high voltage cables

- Etc., can withstand mechanical force and a certain tension. YJLV32 aluminum core XLPE insulated fine steel wire armored PVC sheathed power cable YJV33 copper core XLPE insulated fine steel wire armored PVC sheathed power cable YJLV33 aluminum core XLPE insulated steel tape armored PVC sheathed power cable

- Q: What insulating materials do you need for power tools?

- Reinforced insulation: the voltage between the live parts and the accessible housing is 3750V, such as the voltage between the brush and the cover surface; double insulation: basic insulation + additional insulation. Main insulating material: green paper or DMD Insulation paper for basic insulation; shaft insulation and plastic housing for additional insulation; rotor insulation end plate, stator insulation end plate, used to control the creepage distance and electrical clearance; brush grip bakelite powder, used to strengthen the insulation; other parts (Power plugs, commutators, switches, etc.) These are pressure requirements.

- Q: What is the main purpose of insulating materials?

- As the insulating material has a certain degree of insulation strength, a variety of electrical equipment, all kinds of safety equipment (electrical pliers, test pen, insulated gloves, insulation rods, etc.), a variety of electrical materials, factories are required to allow a certain voltage, For the rated voltage. The voltage to be used shall not exceed its rated voltage value in order to avoid accidents.

- Q: Wear-resistant, high temperature, insulation materials which

- Epoxy, temperature from 100-400 degrees, processing more convenient. Ceramic is the best and cheap.

- Q: What is the thermal aging and electrical aging of insulating materials?

- Environmental aging, also known as atmospheric aging, is due to ultraviolet light, ozone, salt spray, acid and other factors caused by pollution of chemical aging, which is the main reason for ultraviolet light. Thermal aging more common in low-voltage electrical appliances, the mechanism is under the action of temperature, the insulating material in some volatile components escape, the internal components of oxidative cracking, thermal cracking, hydrolysis, molecular chain polymerization and other chemical changes, and gradually lose insulation properties.

1. Manufacturer Overview

| Location | Beijing, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 3 Million |

| Main Markets | North America;Southeast Asia ;Western Europe ;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjing |

| Export Percentage | 60% - 70% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | |

| Product Price Range | High; Average |

Send your message to us

Mica Boards

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 TON m.t.

- Supply Capability:

- 100TON/MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords