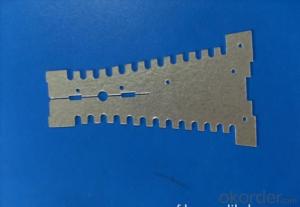

Mica Tube Used in Electric Home Appliances

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

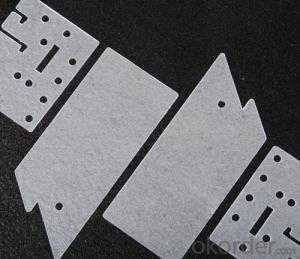

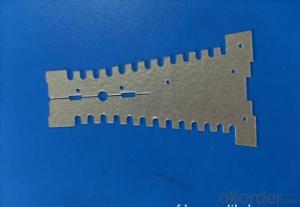

1. Introductions:

Mica tube is made of mica paper with highperformance organic silicon resin. After heating and pressing, the mica plate can be made into rigid or flexible insulating plates. The mica content is about 90% and the organic silicon resin content is 10%.

Mica is a rigid substrate able to withstand very high temperatures and are suited for applications up to 500°F (260°C). Mica heating elements offer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures. Our mica heating element is made by detail order requirments.

2. Applications:

Typical applications of mica heating elements are air heaters, enclosure systems, food service equipment, process and packaging equipment.

3. Main features of Mica Parts:

mica tubes are featured with high strength, good performance, less smoke, less odor etc. This series mica plates are used mainly in household appliances (toaster ovens, microwave ovens, warm air blowers, hair dryers, electric iron etc.), metallurgy (such as linefrequency furnaces, medium frequency furnaces, electric arc furnace, etc.), medical equipment and other industries, used as the heating support, lining plate and partition plate of the electric appliances described above.

4. Technical Parameters:

Tolerance for mica tube | ||

Internal diameter(mm) | Tolerance of ID(mm) | Tolerance of ID(mm) |

<10< span=""> | ±0.3 | ±0.4 |

10 ~ 20 | ±0.4 | ±0.5 |

21 ~ 50 | ±0.5 | ±0.7 |

51 ~ 100 | ±0.6 | ±1.0 |

101 ~ 200 | ±0.8 | ±1.2 |

201 ~ 300 | ±1.0 | ±1.5 |

Length: 10mm to 1000mm | ||

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of mica parts?

Mica laminate and washers made of our own high quality mica plates are used for home appliances, electro-magnets, micro-sensitive control gear etc

---------Which type of mica parts we can produce?

1. Rigid mica parts or Flexible mica parts

2. Muscovite mica parts or phlogopite mica parts

3. Thin mica parts or thick mica parts

4. All the special sized mica parts need drawing.

----------what advantages of mica parts?

1. Good high voltage insulation materials

2. Do not easily break up

3. Easily produce special size

- Q: What is the electrical performance of insulating materials

- The electrical insulating material is a material that is electrically insulated from the device and has a certain mechanical strength, typically having a resistivity of 106 to 1019.cm. Their function in electrical technology is as follows: 1 Insulate the conductor from the other parts; 2 Separate the conductors of different potentials 3 Provide the conditions for the energy storage of the capacitor 4 Improve the potential gradient in the high voltage electric field.

- Q: Brass is not an insulating material?

- Brass is not insulating material. On the contrary is the brass is conductive material. Brass texture hard, can not bend. No copper flexibility is good, so brass can only do a fixed copper conductive use.

- Q: What type of enameled wire and insulation material is used for the compressor

- Motor insulation class The insulation class is divided according to the permissible limit temperature of the insulation material used for the motor. There are Y, A, E, B, F, H, C and several other levels, the allowable limit temperature at all levels as shown in the table below. The so-called permissible limit temperature refers to the permissible maximum operating temperature of the motor insulation material, which reflects the heat resistance of the insulating material. Insulation material is divided into Y grade, A grade, grade E, grade B, grade F, grade H, grade C, permissible temperature (℃) 90,105,120,130,155,180, 180 ℃ or higher.

- Q: Insulation material and the definition of the role of the best professional insulation materials website for my reference

- The main indicators affect the performance of insulating materials 1, insulation resistance, resistivity: resistance is the reciprocal of conductance, the resistivity is the resistance per unit volume. The smaller the conductivity of the material, the greater the resistance, the reciprocal relationship between the two, for the insulation material, always want the resistivity as high as possible. 2, the relative dielectric constant and dielectric loss tangent:

- Q: What insulating material is used for high voltage cables

- YJLV23 Aluminum core XLPE insulated steel tape armored PVC sheathed power cable YJV32 copper core XLPE insulated fine steel wire armored PVC sheathed power cable indoor, tunnel, cable trench, shaft or buried

- Q: Who knows what are the ability of 1300 degrees above the high temperature, insulation materials?

- Heat-resistant polymers can be used as high temperature resistant film insulation materials, high temperature resistant fibers, high temperature resistant coatings, high temperature adhesives. In accordance with the high temperature of the time, but also sub-instant high temperature materials and high temperature materials for a long time. The former in 1000 ~ 10000 ℃ can withstand a few seconds to a few minutes.

- Q: What is the insulating material in the middle of the connecting wire?

- The original wire is insulated paint, you often use, you can also use quick-drying insulating paint.

- Q: What are the commonly used insulating materials?

- Mainly used for motor, electrical winding insulation, switch the bottom plate and insulators, etc. Organic insulation materials are: shellac, resin, rubber, cotton yarn, paper, linen, rayon,

- Q: Wear-resistant, high temperature, insulation materials which

- Epoxy, temperature from 100-400 degrees, processing more convenient. Ceramic is the best and cheap.

- Q: What insulating material is best `?

- Liquid insulation material, also known as insulating oil. Fill the internal or inter-electrode gap between the solid material to improve its dielectric properties and improve the cooling capacity of the equipment. Liquid insulation material high breakdown strength, dielectric loss tangent (tgσ) small, insulation resistance High specific dielectric constant, in addition, also has excellent physical and chemical properties, such as high gasification temperature, high flash point, low freezing point, thermal conductivity, thermal stability, in the electric field under the suction Small and so on.

Send your message to us

Mica Tube Used in Electric Home Appliances

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords