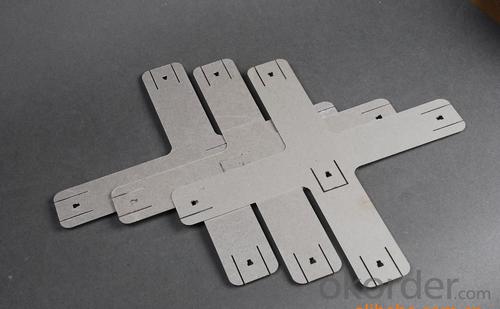

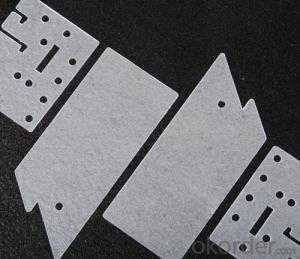

Mica Parts Used as the Heating Support

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introductions:

Mica is a rigid substrate able to withstand very high temperatures and are suited for applications up to 500°F (260°C). Mica heating elementsoffer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures. Our mica heating element is made by detail order requirments.

Mica plate is made of mica paper with high performance organic silicon resin. After heating and pressing, the mica plate can be made into rigid or flexible insulating plates. The mica content is about 90% and the organic silicon resin content is 10%.

2. Main features of Mica Parts:

Rigid mica plates are featured with high strength, good performance, less smoke, less odor etc. This series mica plates are used mainly in household appliances (toaster ovens, microwave ovens, warm air blowers, hair dryers, electric iron etc.), metallurgy (such as line frequency furnaces, medium frequency furnaces, electric arc furnace, etc.), medical equipment and other industries, used as the heating support, lining plate and partition plate of the electric appliances described above.

3. Applications:

Typical applications of mica heating elements are air heaters, enclosure systems, food service equipment, process and packaging equipment.

4. Technical Parameters:

ITEM | UNIT | RM | RP | RM-T | RP-T | FM | FP | |

Hardness |

| Rigid | Rigid | Rigid | Rigid | Flexible | Flexible | |

Mica paper |

| Muscovite | Phlogopite | Muscovite | Phlogopite | Muscovite | Phlogopite | |

Thickness | mm | 0.1-2.0 | 0.1-2.0 | 3.0-50 | 3.0-50 | 0.1-2.0 | 0.1-2.0 | |

Mica content | % | ≥90 | ≥90 | >88 | >88 | ≥90 | ≥90 | |

Bond Content | % | <10< span=""> | <10< span=""> | <12< span=""> | <12< span=""> | <10< span=""> | <10< span=""> | |

Density | g/m 3 | 1.6~2.45 | 1.6~2.45 | 2.1~2.4 | 2.1~2.4 | 1.6~2.45 | 1.6~2.45 | |

Heat | Continuous | ℃ | 500 | 700 | 500 | 700 | 500 | 700 |

Peak | ℃ | 700 | 900 | 700 | 900 | 700 | 900 | |

Heat loss at 500℃ | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | <1< span=""> | <1< span=""> | |

Heat loss at 700℃ | % | <2< span=""> | <2< span=""> | <1< span=""> | <2< span=""> | <2< span=""> | <2< span=""> | |

Flexural strength | Mpa | >160 | >140 | — | — | <1< span=""> | <1< span=""> | |

Water absorption 24h/23°C | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | — | — | |

Dielectric strength | KV/mm | >20 | >20 | >15 | >15 | >15 | >15 | |

Volume | 23℃ | ΩNaN | >1017 | >1017 | >1017 | >1017 | — | — |

500℃ | ΩNaN | >1012 | >1012 | >1012 | >1012 | — | — | |

Smoking Test | s | <4< span=""> | <4< span=""> | — | — | — | — | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of mica parts?

Mica laminate and washers made of our own high quality mica plates are used for home appliances, electro-magnets, micro-sensitive control gear etc

---------Which type of mica parts we can produce?

1. Rigid mica parts or Flexible mica parts

2. Muscovite mica parts or phlogopite mica parts

3. Thin mica parts or thick mica parts

4. All the special sized mica parts need drawing.

----------what advantages of mica parts?

1. Good high voltage insulation materials

2. Do not easily break up

3. Easily produce special size

- Q: What is the 8 ° C rule for insulating materials?

- Such as A-class insulation material limit working temperature of 105 ℃, when the ultimate operating temperature of 8 ℃, its life will be reduced by about half, which is 8 ℃ thermal deterioration rules.

- Q: What type of enameled wire and insulation material is used for the compressor

- Motor insulation class The insulation class is divided according to the permissible limit temperature of the insulation material used for the motor. There are Y, A, E, B, F, H, C and several other levels, the allowable limit temperature at all levels as shown in the table below. The so-called permissible limit temperature refers to the permissible maximum operating temperature of the motor insulation material, which reflects the heat resistance of the insulating material. Insulation material is divided into Y grade, A grade, grade E, grade B, grade F, grade H, grade C, permissible temperature (℃) 90,105,120,130,155,180, 180 ℃ or higher.

- Q: What insulating materials are used for transformers

- Some of the transformer plants in the United States, such as FPT in Virginia, have developed a NOMEX? Aromatic Polyamide using DuPont as a primary insulated dry-type transformer. FPT products are available in two models: FB type 180 ℃ (H level) of the insulation system. FH type 220 ℃ (C level) of the insulation system, the coil temperature rise were 115K (China 125K) and 150K. Its low-voltage coil is foil-type or multi-layer and laminated, and NOMEX? is used for both turn insulation and interlayer insulation. The high-pressure coil is a cake, and the wire is wrapped in NOMEX? paper. The barcakes do not have a conventional stay and a pad, and the comb is used to reduce the maximum voltage of the cake by half. The high-voltage coil of the axial short-circuit resistance, but increased the coil winding system and manufacturing time. High and low voltage coil for nesting, enhanced mechanical strength.

- Q: Who knows what are the ability of 1300 degrees above the high temperature, insulation materials?

- Where the ablative material is also high temperature resistant material. For example, in the 300 ~ 600 ℃, in the air to maintain its mechanical strength, chemical resistance and so on.

- Q: What insulating materials are used for high frequency transformers?

- Can be brush, can be sprayed, can be baked Here is the main raw material for ice making. Selection of industrial products. All around the paint factory production. General high-frequency transformer insulation materials used by the scope and form are divided into: impregnated paint, covering paint, silicon steel paint, anti-corona paint four.

- Q: What is the insulating material in the middle of the connecting wire?

- The original wire is insulated paint, you often use, you can also use quick-drying insulating paint.

- Q: What are the gas insulation materials?

- The relative breakdown strength of air (at air 1) at the standard pressure (101335Pa) is as follows: nitrogen, 1; hydrogen, 0.5; carbon dioxide, 0.9; sulfur hexafluoride, 2.5; freon-12,2.7 The

- Q: What is the DMD insulation material?

- DMD insulating paper, the product is a layer of polyester film coated with adhesive, one side for the polyester fiber non-woven composite, calendering from a composite insulation products, referred to as DMD.

- Q: Wear-resistant, high temperature, insulation materials which

- Polytetrafluoroethylene (engineering plastics) - (- 195 ~ 250) ℃ can be used for a long time. For corrosion-resistant parts, anti-friction wear parts, seals, insulation and so on. Silicone rubber - Upper temperature limit (100 to 300) ° C. For high and low temperature parts, insulation, pipe joints and so on. Fluorine rubber - the use of the upper temperature of 300 ℃, for chemical lining, senior seals, high vacuum plastic parts.

- Q: What insulating material is best `?

- Insulation materials, also known as insulation materials. Insulation material refers to the electrical insulation material, the conductivity of about 10-10 West / m below. According to the needs of different electrical products, but also from the storage Can, heat, cooling, arc, moisture, mildew, anti-corrosion, anti-radiation, mechanical support and fixed, protective conductor and so on.

Send your message to us

Mica Parts Used as the Heating Support

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords